Connecting rod type crankshaft-free engine

A technology without crankshaft and engine, applied in the field of fuel engine and connecting rod type crankless engine, can solve the problems of large exhaust gas emission, insufficient cylinder combustion, low internal combustion engine heat engine efficiency, etc., to achieve high heat engine efficiency, not easy to slip, transmission great effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

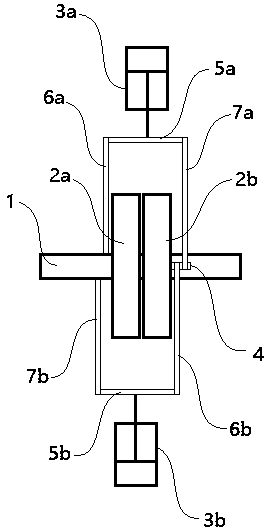

[0037] see figure 1 with figure 2 Shown, a kind of connecting rod type crankshaftless engine comprises output shaft 1, first one-way wheel 2a, second one-way wheel 2b, first piston 3a and second piston 3b; Said first one-way wheel 2a and The second one-way wheels 2b are both sleeved on the output shaft 1, the effective rotation directions of the first one-way wheels 2a and the second one-way wheels 2b are the same, and the first one-way wheels 2a and the left or right end of the outer surface of the second one-way wheel 2b are provided with a short connecting shaft 4; the first piston 3a and the second piston 3b are respectively arranged on the upper and lower sides of the output shaft 1 , the piston rod of the first piston 3a is provided with a first long connecting shaft 5a, the piston rod of the second piston 3b is provided with a second long connecting shaft 5b, the first long connecting shaft 5a and the first long connecting shaft 5a The two long connecting shafts 5b a...

Embodiment 2

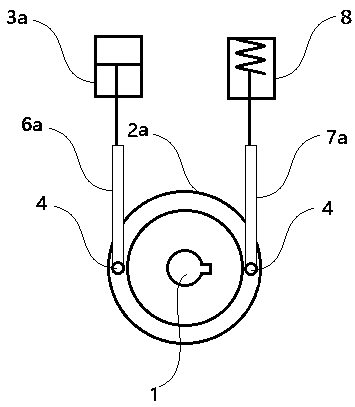

[0040] see image 3 As shown, a connecting rod type crankshaftless engine includes an output shaft 1, a first one-way wheel 2a, a first piston 3a and an air spring 8; the first one-way wheel 2a is sleeved on the output shaft 1 , the left and right ends of the outer surface of the first one-way wheel 2a are respectively provided with a short connecting shaft 4; the first piston 3a is located above or below the short connecting shaft 4, and is connected to The rod 6a is connected to the short connecting shaft 4, the air spring 8 is located above or below the other short connecting shaft 4, and is connected to the short connecting shaft through the first driven connecting rod 7a. 4 connections.

[0041] Further, when the effective rotation direction of the first one-way wheel 2a is counterclockwise, the first piston 3a is arranged above the short connecting shaft 4 on the left side or the short connecting shaft 4 on the right side. Below the connecting shaft 4, the air spring 8...

Embodiment 3

[0043] see Figure 4 with Figure 5 As shown, the first one-way wheel 2a and the second one-way wheel 2b have the same structure, and both include an output disc 201, a transmission wheel 202, a one-way locking mechanism and a supporting bearing mechanism. The transmission wheel 202 is sheathed outside the output disc 201, and the output disc 201 is detachable. A shaft mounting hole 203 and a shaft positioning groove 204 for mounting the output shaft are provided in the center of the output disc 201 .

[0044] Between the output disk 201 and the transmission wheel 202, there are 4-8 one-way locking mechanisms. Each one-way locking mechanism includes a wedge-shaped groove 205 provided on the circumference of the output disk 201, the bottom surface, front side, rear side and inner side of the wedge-shaped groove 205 are closed surfaces, and the wedge-shaped groove The outer surface of 205 is an open surface, and the bottom surface, front side, rear side, and inner surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com