High-water-pressure shield tunnel segment joint multi-channel waterproof device of reserved grouting hole

A technology of shield tunnel segment and waterproof device, which is applied to tunnels, tunnel linings, shaft equipment, etc., can solve the problems of large local shear force at the corners of segments, limited closing compression force, and damage at the corners of segments, etc. Achieve the effect of reducing time costs and construction costs, reducing long-term performance considerations, and reducing operation and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

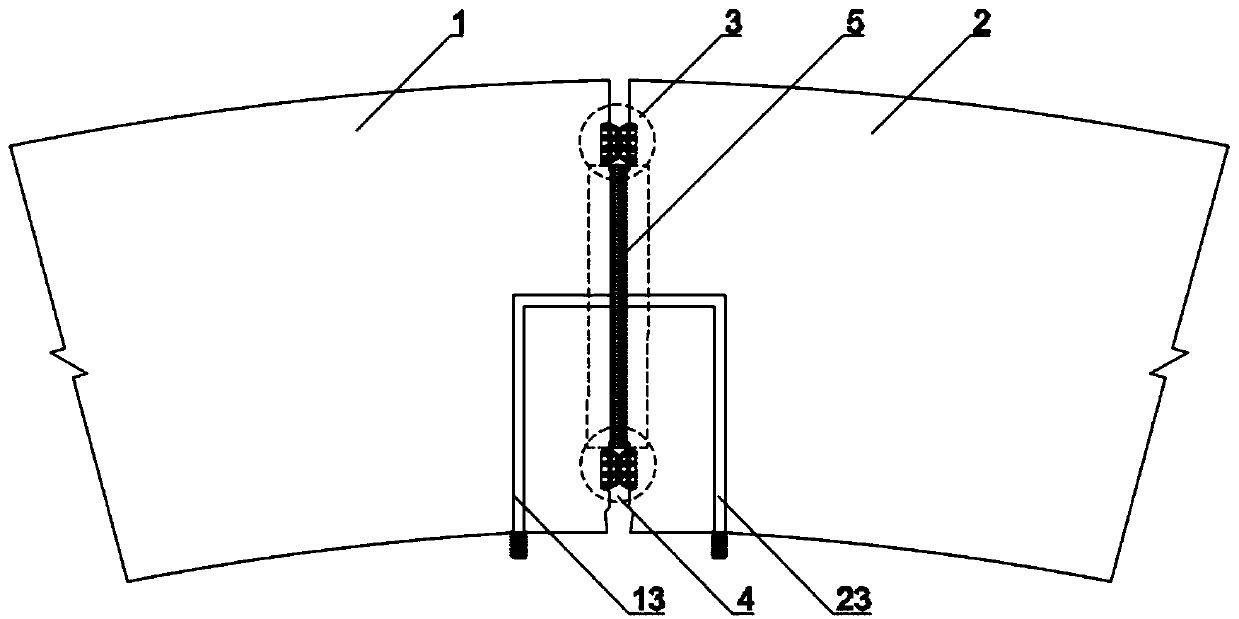

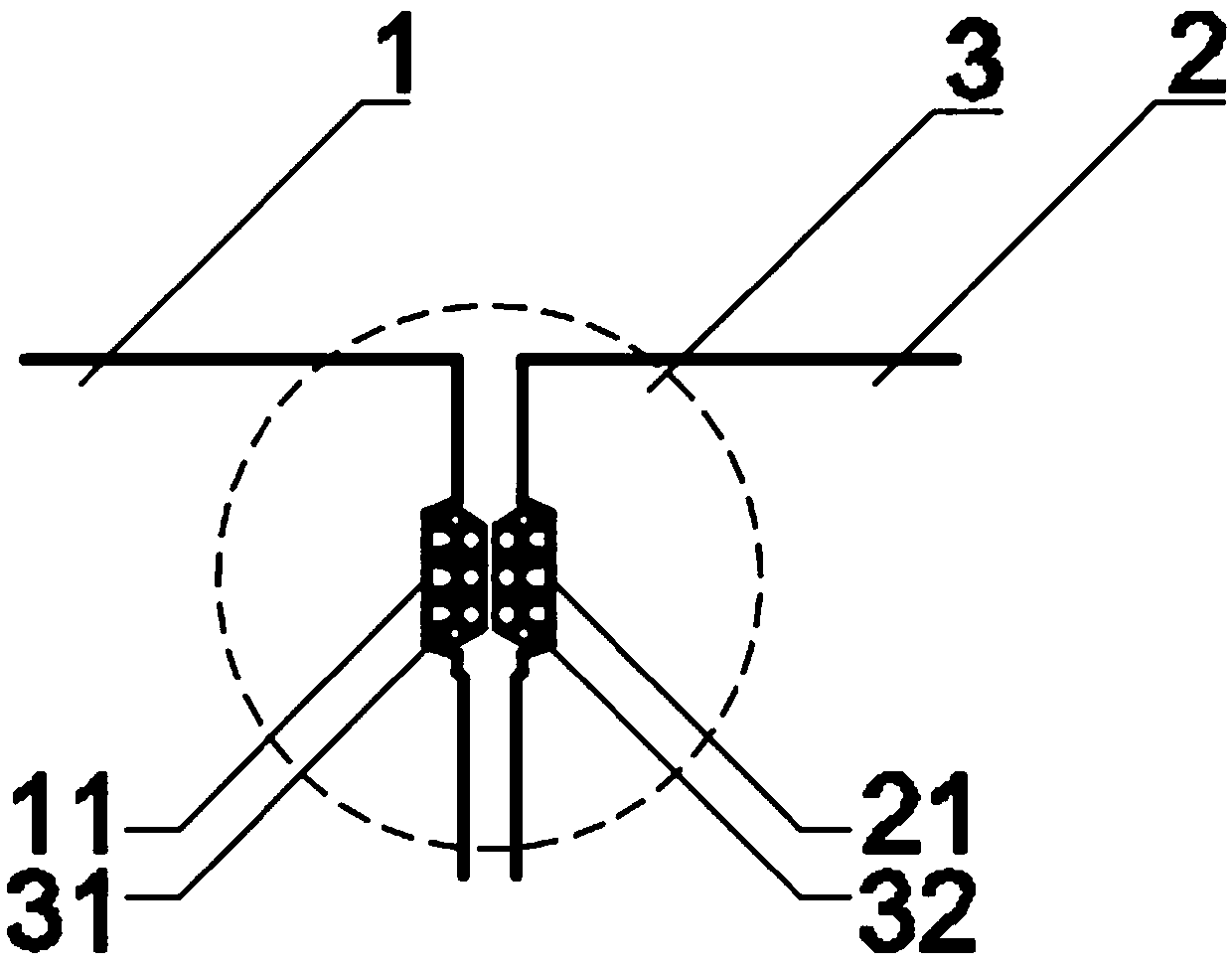

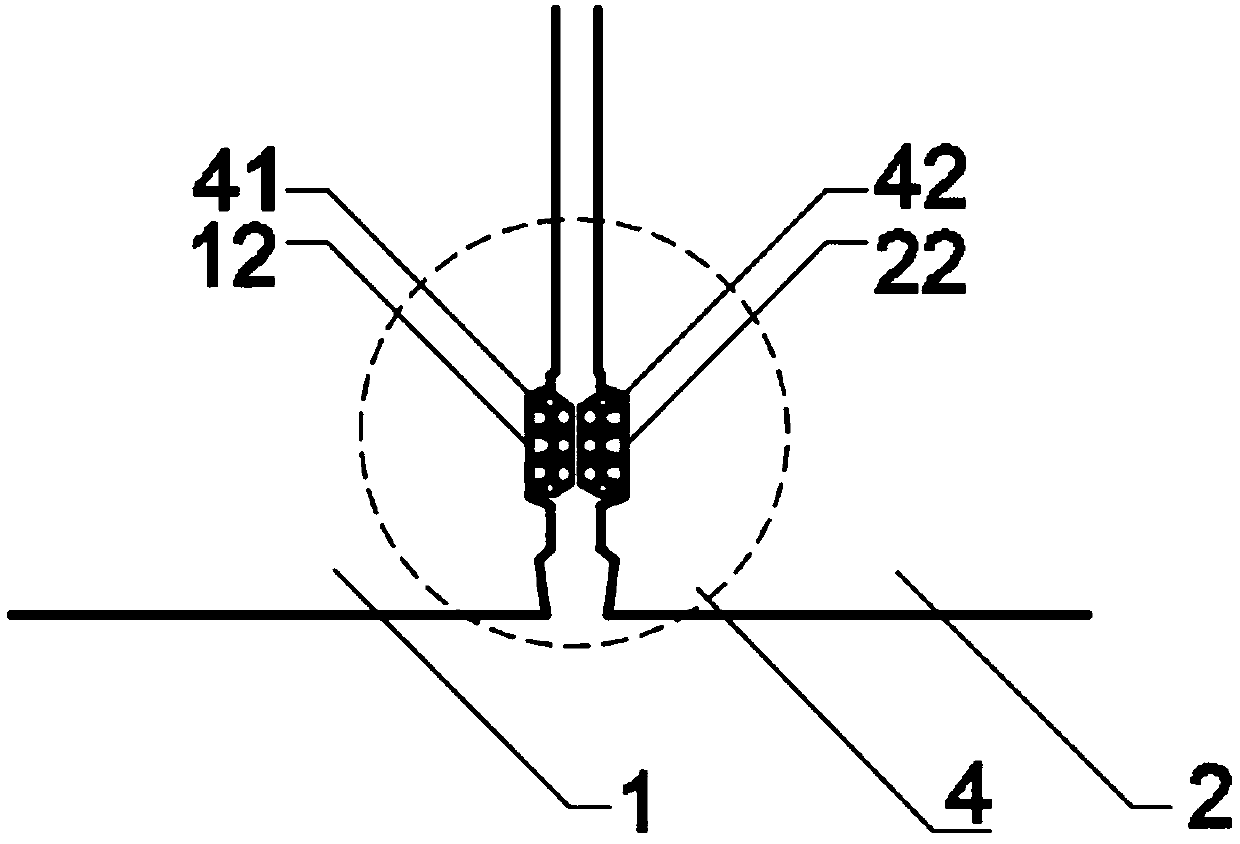

[0038] Such as Figure 1-4 As shown, the high hydraulic pressure shield tunnel segment joint multi-channel waterproof device with reserved grouting holes of the present invention comprises: the first shield tunnel segment (1), the second shield tunnel segment (2), The first elastic gasket waterproof structure (3), the second elastic gasket waterproof structure (4) and the third grouting layer waterproof structure (5). The first shield tunnel segment (1) is provided with a first outer sealing gasket groove (11), a first inner sealing gasket groove (12) and a first embedded grouting pipe (13). The second shield tunnel segment (2) is provided with a second outer sealing gasket groove (21), a second inner sealing gasket groove (22) and a pre-buried grouting pipe (23).

[0039] The first elastic gasket waterproof structure (3) consists of the first outer elastic gasket (31) pasted on the first outer gasket groove (11) of the first shield tunnel segment (1) and the first outer gask...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com