Bearing and energy-dissipation difunctional corrugated steel plate wall

A corrugated steel plate, dual-function technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of low vertical bearing capacity, low lateral and buckling bearing capacity, limited hysteretic performance, and steel plate wall deformation, etc. Reduced welding workload, high anti-side and energy efficiency, and reduced plate thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to further illustrate the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, but they should not be construed as limiting the protection scope of the present invention.

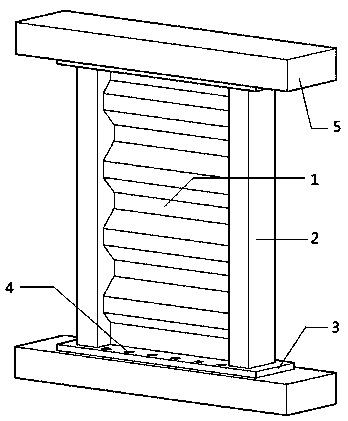

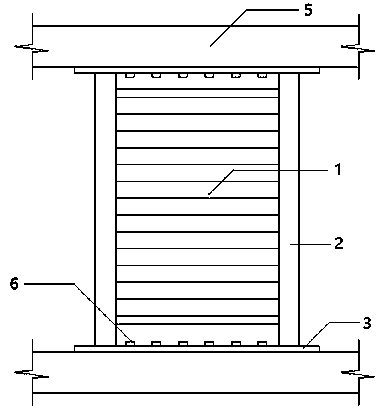

[0019] like figure 1 , 2 As shown, a corrugated steel plate wall with dual functions of load-bearing and energy-dissipating in the present invention includes: an anti-seismic energy-dissipating element located in the center, that is, a non-buckling corrugated steel plate energy-dissipating wall 1 and square steel tube concrete column members 2 on both sides, and a buckling-free corrugated steel plate The energy-dissipating wall 1 is connected to the square steel tube concrete column members 2 on the left and right sides by welding. The upper and lower ends of the square steel tube concrete column members 2 are respectively welded with a bottom plate 3, and the bottom plate 3 is provided with bolt holes 4. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com