A prefabricated assembly pipe gallery structure

A technology of prefabricated assembly and pipe gallery, applied in underwater structures, infrastructure engineering, construction, etc., can solve the problems of comprehensive pipe gallery damage, uneven resistance to foundation, leakage of comprehensive pipe gallery, etc., and achieves good anti-seepage performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

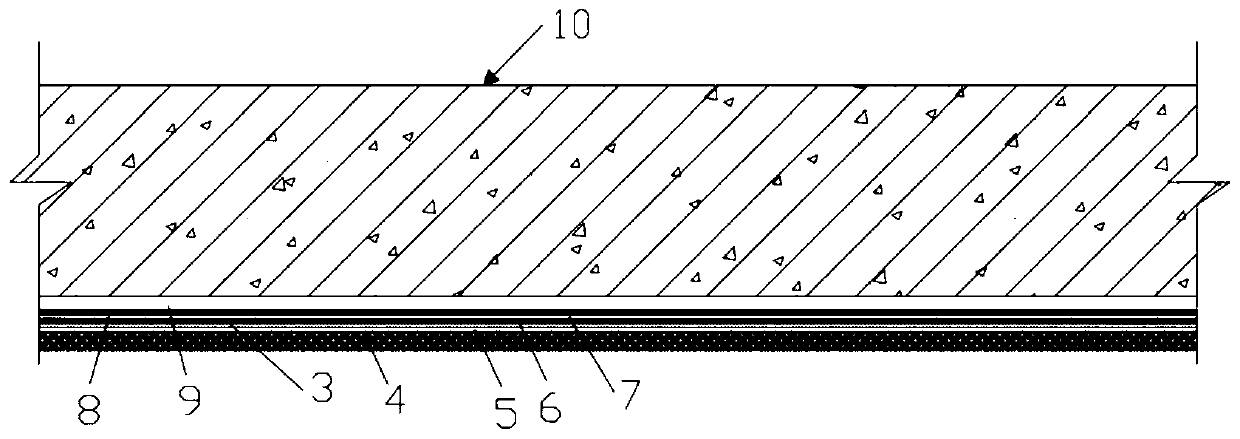

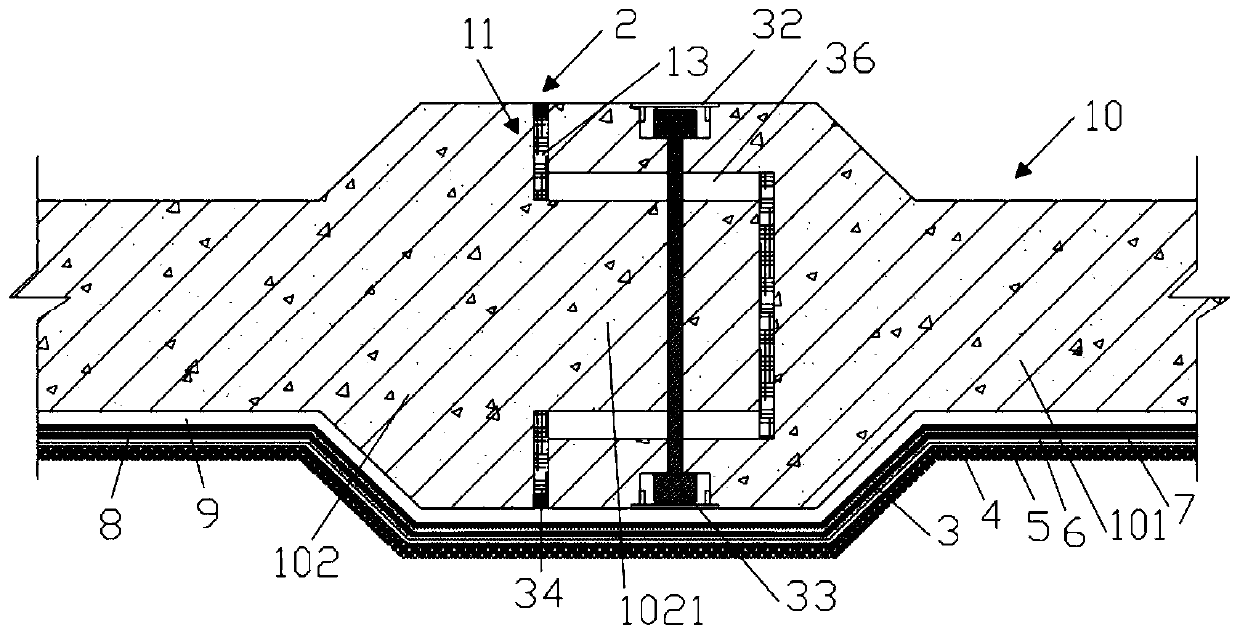

[0041] figure 2 A sectional view of the bottom plate 10 and a sectional view of the bottom deformation seam 2 are shown, as figure 2 As shown, the bottom of the base plate 10 of the underground comprehensive utility gallery is laid with a first waterproof layer 3. Before the construction of the base plate 10, the backfill soil layer 4 is formed by layering and compacting before the bottom of the underground comprehensive utility gallery. Pour 100mm thick fine stone concrete on top to form a cushion layer 5, which is compacted as it is beaten, and pour a 1:2.5 cement mortar leveling layer 6 on the cushion layer 5, and then place it on the cement mortar leveling layer 6 Lay the first waterproof layer 3 of the waterproof membrane, the material of the first waterproof layer 3 is SBS modified asphalt root puncture resistant waterproof membrane, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com