Microporous PTFE composite carbon nanotube paper and preparation method thereof

A carbon nanotube and PTFE technology, which is applied in the field of microporous PTFE composite carbon nanotube paper and its preparation, can solve the problems of decreased hydrophobicity, inability to directly borrow the pore-making method, low plasticity, etc., and achieves improved elongation at break, The effect of maintaining superhydrophobicity and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

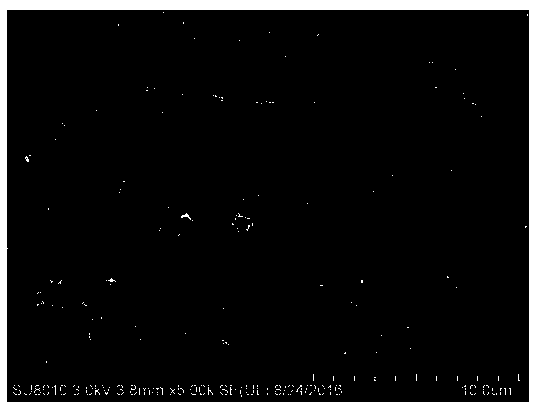

[0023] Embodiment 1: As shown in Figure 1, this microporous PTFE composite carbon nanotube paper is uniformly compounded by PTFE and carbon nanotubes, and has a network-like cross-overlapping structure, with uniform micropores, and PTFE is evenly distributed on the hole walls, which is super-hydrophobic Pores, thickness 49±3um, air permeability 15.4μm / (Pa•s), elongation at break 126±5%, resistivity 362±24mΩ.cm, static contact angle 139°±9°.

[0024] The preparation method of microporous PTFE composite carbon nanotube paper, the specific preparation steps are as follows:

[0025] (1) Preparation of basic materials: Mix PTFE emulsion and carbon nanotube dispersion evenly, the mass ratio of PTFE and CNTs is 8:1, the micropores are formed by suction filtration with a microporous filter membrane with a pore size of 1 μm; the wool blanket is sandwiched, at 120 Dry at ℃ for 40 minutes, after drying, the carbon paper is separated from the substrate, the carbon paper is sintered, and t...

Embodiment 2

[0030] Example 2: This microporous PTFE composite carbon nanotube paper is uniformly composited by PTFE and carbon nanotubes, and has a network-like cross-overlapping structure, with uniform micropores, PTFE is evenly distributed on the hole walls, and it is a super-hydrophobic hole with a thickness of 57 ± 5um , air permeability 9.5μm / (Pa•s), elongation at break 193±30%, resistivity 297±19mΩ.cm, static contact angle 142°±9°.

[0031] The preparation method of microporous PTFE composite carbon nanotube paper, the specific preparation steps are as follows:

[0032] (1) Preparation of basic materials: Mix PTFE emulsion and carbon nanotube dispersion evenly, the mass ratio of PTFE and CNTs is 3:1, the micropores are formed by suction filtration with a microporous filter membrane with a pore size of 1 μm; the wool blanket is sandwiched, at 120 Dry at ℃ for 40 minutes, after drying, the carbon paper is separated from the substrate, the carbon paper is sintered, and the muffle furna...

Embodiment 3

[0037] Example 3: This microporous PTFE composite carbon nanotube paper is uniformly composited by PTFE and carbon nanotubes, and has a network-like cross-overlapping structure, with uniform micropores, PTFE is evenly distributed on the hole walls, and it is a super-hydrophobic hole, with a thickness of 82 ± 5um , air permeability 2.7μm / (Pa•s), elongation at break 210±45%, resistivity 195±8mΩ.cm, static contact angle 140°±5°.

[0038] The preparation method of microporous PTFE composite carbon nanotube paper, the specific preparation steps are as follows:

[0039](1) Preparation of basic materials: Mix PTFE emulsion and carbon nanotube dispersion evenly, the mass ratio of PTFE and CNTs is 3:1, the micropores are formed by suction filtration with a microporous filter membrane with a pore size of 1 μm; the wool blanket is sandwiched, at 120 Dry at ℃ for 40 minutes, after drying, the carbon paper is separated from the substrate, the carbon paper is sintered, and the muffle furnac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com