A kind of vacuum induction furnace smelting rapid denitrification method

A vacuum induction furnace and denitrification technology, applied in furnaces, electric furnaces, furnace types, etc., can solve problems such as the decrease of working vacuum, the number of oxide inclusions and slag, and the effect of denitrification, and achieve the effect of small erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

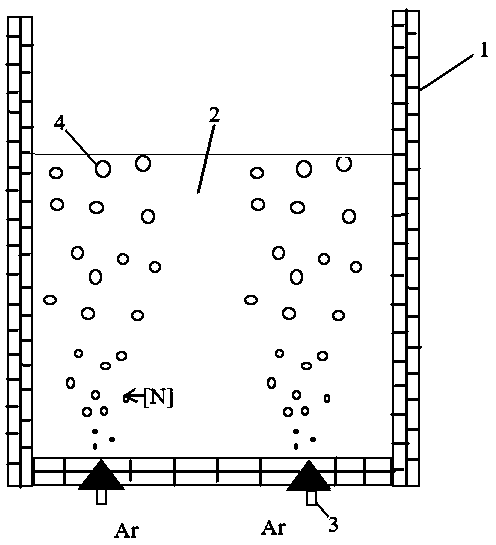

Image

Examples

Embodiment 1

[0016] Turn on the argon gas switch, check whether the two gas permeable bricks at the bottom of the crucible are normal, if not, replace the smelting preparation stage, estimate according to the oxygen content of the main raw materials such as electrolytic nickel plate, industrial pure iron, medium carbon ferrochrome, etc., according to the mass fraction of 50% The ratio is mixed with carbon powder and placed on the bottom of the crucible. Close the furnace cover and start vacuuming until the absolute vacuum reaches about 10 -2 Pa, and the static air leakage rate does not exceed 300Pa.L / s, if it is abnormal, it needs to be checked and dealt with. When electrified and melted, sufficient carbon-oxygen reaction helps to remove part of N. After the charge is completely melted, turn on the bottom blowing argon switch and adjust the flow rate or pressure, and observe that there are obvious bubbles escaping from the surface of the molten pool, and the time is 30 minutes. After the...

Embodiment 2

[0018] Turn on the argon gas switch, check whether the two gas permeable bricks at the bottom of the crucible are normal, and replace them if they are abnormal.

[0019] In the smelting preparation stage, according to the estimation of the oxygen content of the main raw materials such as industrial pure iron, electrolytic nickel plate, ferrosilicon, etc., the corresponding carbon powder is mixed in the proportion of 150% by mass fraction and placed at the bottom of the crucible. Close the furnace cover and start vacuuming until the absolute vacuum reaches about 10 -2 Pa, and the static air leakage rate does not exceed 300Pa.L / s, if it is abnormal, it needs to be checked and dealt with. When electrified and melted, sufficient carbon-oxygen reaction helps to remove part of N. After the charge is completely melted, turn on the bottom blowing argon switch and adjust the flow rate or pressure, and observe that there are obvious bubbles escaping from the surface of the molten pool,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com