A medium and high temperature heat pump mixed working fluid

A mixed working medium and high-temperature heat pump technology, which is applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve problems such as insufficient lubrication, poor oil return, excessive lubricant retention, etc., to reduce friction and improve heat transfer efficiency , the effect of reducing environmental protection requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the lubricating compatibilizer is as follows: in parts by weight, take 100 parts of poly-butene-1, 1-5 parts of 1,4,8,11-tetraazatetracyclo[4,11]diene , 0.01 to 0.06 parts of 2,4,6-tripyridyl triazine europium, 1 to 4 parts of benzoyl peroxide and 5 to 20 parts of white oil, react at a temperature of 40 to 60 ° C for 7 to 15 hours to get the product.

[0032] A method for preparing a medium-high temperature heat pump mixed working fluid as described above is adopted:

[0033] Physically mix 1,1,2,2-tetrafluoroethane, difluoroethane, and a lubricant compatibilizer in a liquid state according to the ratio to obtain a medium-high temperature new working medium suitable for normal temperature heat pump units.

Embodiment 1

[0037] Preparation of lubricant compatibilizer: by weight, 100 parts of poly-butene-1, 3 parts of 1,4,8,11-tetraazatetracyclo[4,11]diene, 0.03 parts of 2,4, 6-tripyridyltriazine europium, 2 parts of benzoyl peroxide, 13 parts of white oil, reacted at 48°C for 11 hours to obtain the product.

[0038] Preparation of refrigerant:

[0039] 1,1,2,2-Tetrafluoroethane 71%

[0040] Difluoroethane 28.5%

[0041] Lubrication compatibilizer 0.5%

[0042]The medium and high temperature new working fluid suitable for normal temperature heat pump units can be obtained by physically mixing the above various components according to their corresponding proportions in the liquid phase state.

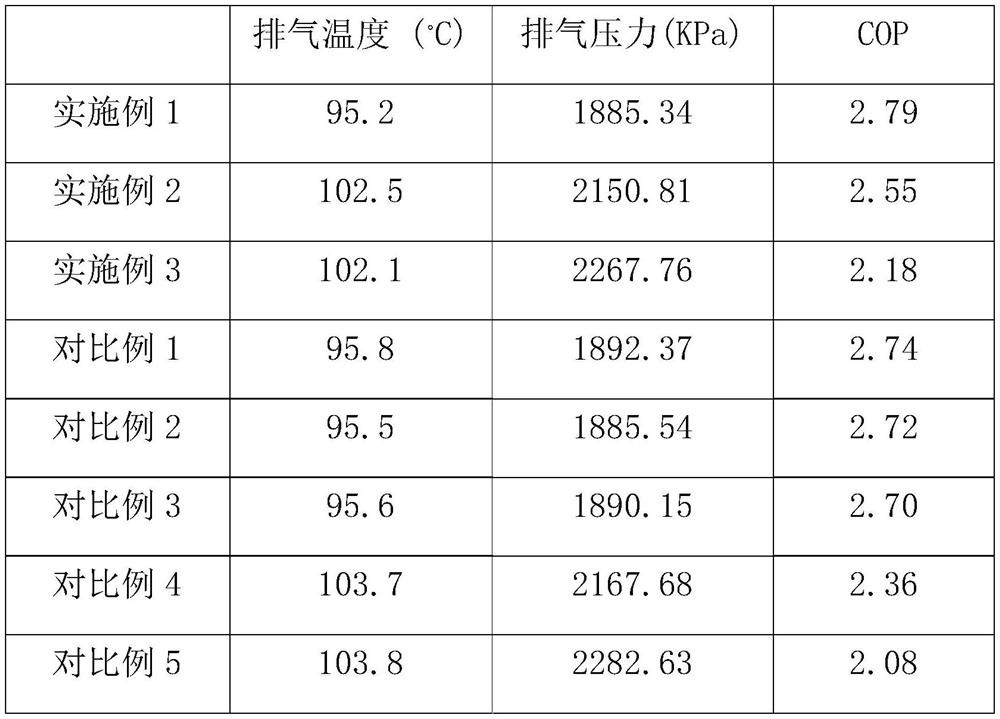

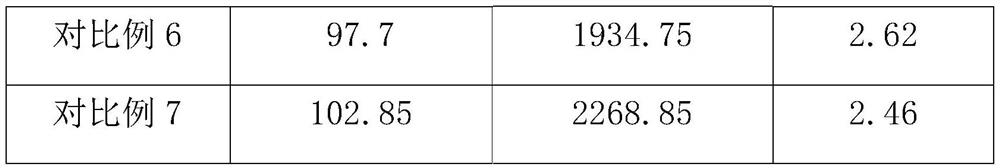

[0043] The working medium of the present invention is directly poured into the existing HFC-134a air conditioning unit (without changing the lubricating oil), and converted into a medium-high temperature heat pump unit with a new working medium, and the cycle energy efficiency and the matching degree o...

Embodiment 2

[0046] Preparation of lubricant compatibilizer: by weight, 100 parts of poly-butene-1, 1 part of 1,4,8,11-tetraazatetracyclo[4,11]diene, 0.01 part of 2,4, 6-tripyridyl triazine europium, 1 part of benzoyl peroxide, 5 parts of white oil, react at 40°C for 15 hours to obtain the product.

[0047] Preparation of refrigerant:

[0048] 1,1,2,2-Tetrafluoroethane 60%

[0049] Difluoroethane 39.9%

[0050] Lubrication compatibilizer 0.1%

[0051] The medium and high temperature new working fluid suitable for normal temperature heat pump units can be obtained by physically mixing the above various components according to their corresponding proportions in the liquid phase state.

[0052] The design conditions of the heat pump system are taken as: the average evaporation temperature is 15°C, the average condensation temperature is 75°C, the constant entropy efficiency of the compression process is 80%, and there is no supercooling and superheating regulation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com