A mnbr biological filler for nitrogen and phosphorus removal

A bio-filler, nitrogen and phosphorus removal technology, applied in sustainable biological treatment, biological water/sewage treatment, water pollutants, etc. , to achieve the effect of accelerating the formation and adhesion, fast film hanging, and strong impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

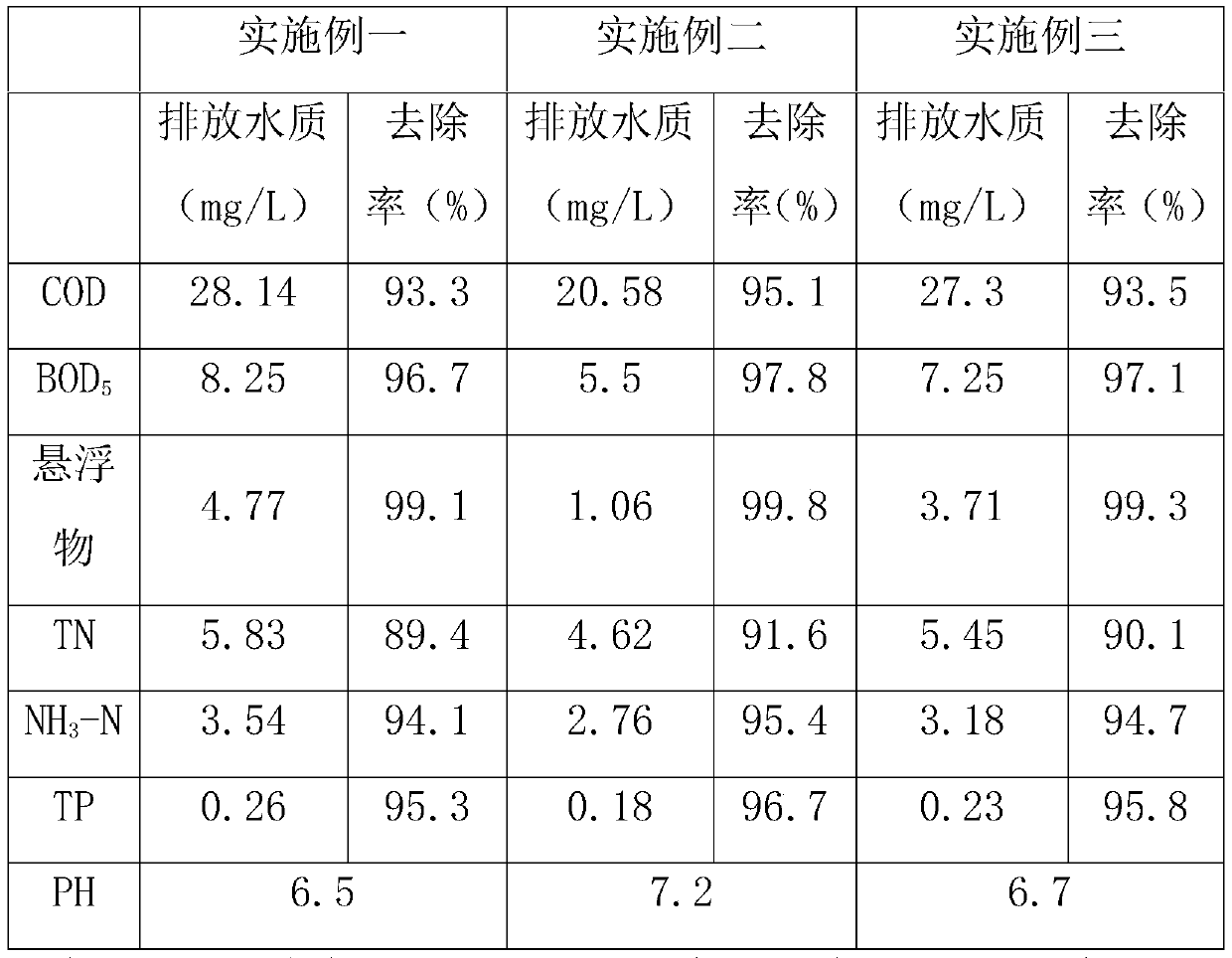

Embodiment 1

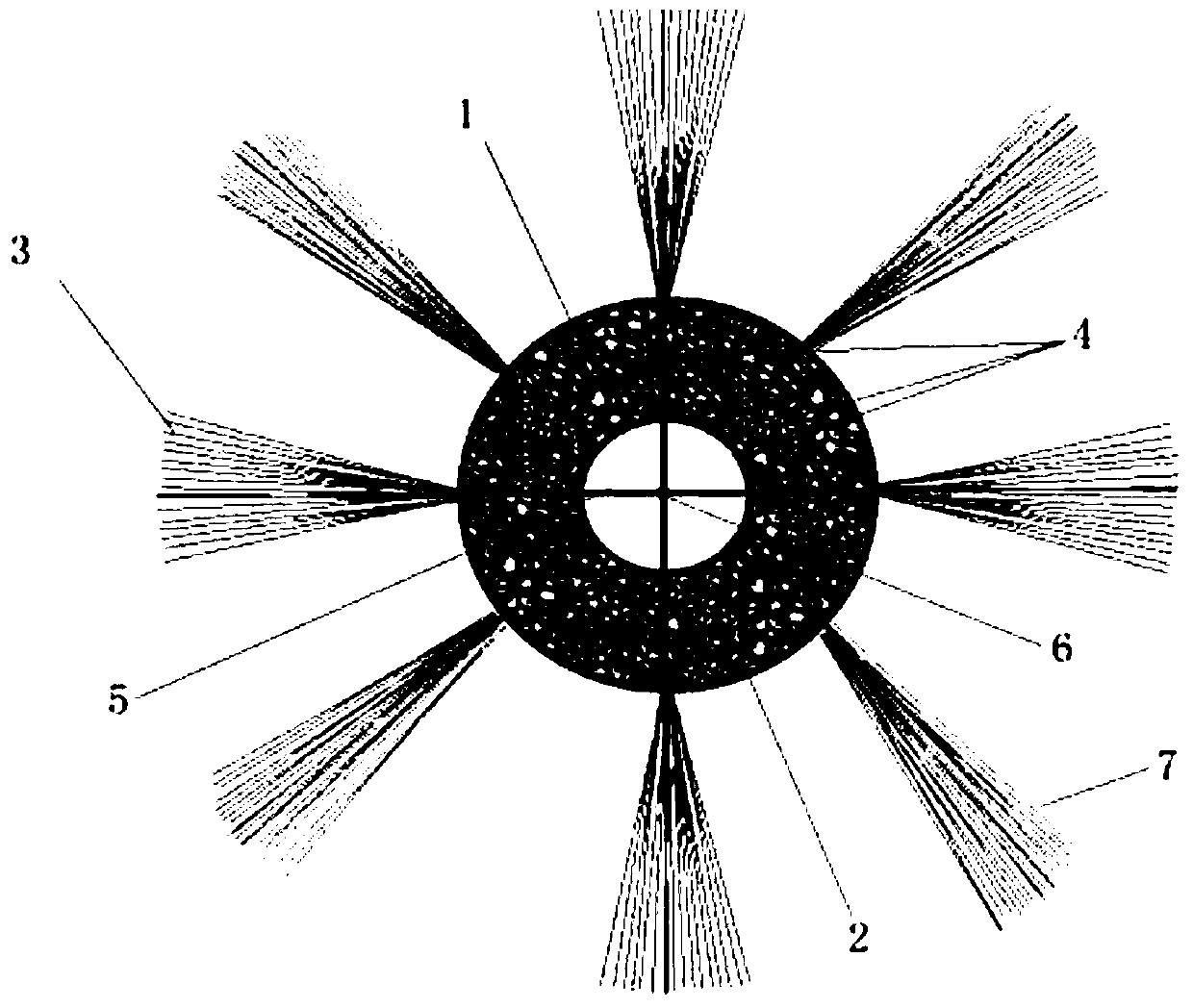

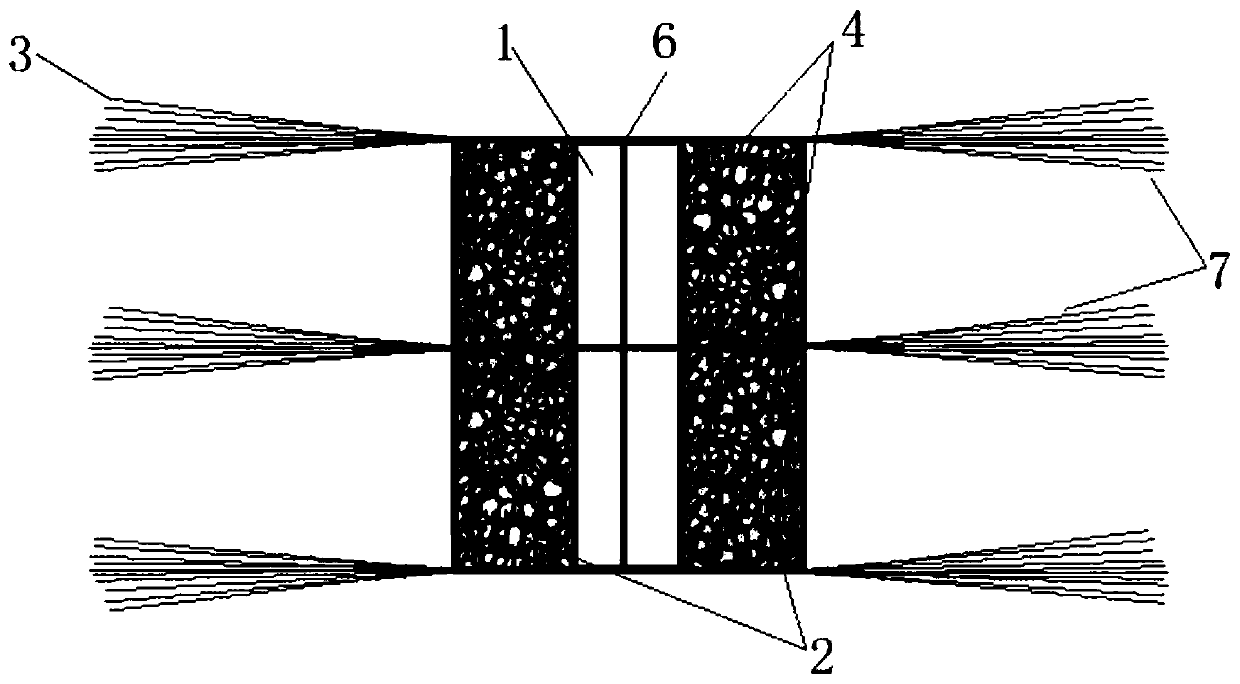

[0026] Such as Figure 1-2 As shown, the present invention provides a MNBR biological filler for denitrification and phosphorus removal. The biological filler is cylindrical as a whole; the biological filler includes: an inner ring layer 1, a middle ring layer 2, an outer ring layer 3, and a filler matrix; the filler matrix includes a membrane shell Skeleton 4, tie bars 5, central axis 6; outer ring layer 3 is set on the periphery of the packing matrix; central axis 6 runs through the entire packing matrix up and down; tie bars 5 are supported between the central axis 6 and middle ring layer 2; inner ring layer 1 It is arranged in the middle of the membrane shell skeleton 4; the middle ring layer 2 is arranged on the periphery of the inner ring layer 1;

[0027] The middle ring layer 2 is filled with three-dimensional porous fibers; the outer ring layer 3 is radially distributed filamentary fibers 7; the outer ring layer 3 is provided with 8 groups of filamentary fibers 7; eac...

Embodiment 2

[0041] Biological filler structure is the same as embodiment one

[0042] The filler matrix includes the following raw materials in parts by weight: 45 parts of polypropylene, 32 parts of polyvinyl chloride, 14 parts of polyvinyl alcohol, 5 parts of polyacrylamide, 2 parts of antioxidant, and the antioxidant is 1:0.03:0.6 in mass ratio A composition of molecular sieves, 2,6-di-tert-butyl-p-cresol and boron nitride;

[0043] The preparation method of filler matrix comprises the following steps:

[0044] S1. Molecular sieves, 2,6-di-tert-butyl-p-cresol and boron nitride are jointly added to a fine grinder according to the mass ratio, and fully ground for 0.4h to obtain an antioxidant;

[0045] S2. Add the polypropylene, polyvinyl chloride, polyvinyl alcohol, polyacrylamide and antioxidant of the specific gravity into the high mixer, and mix thoroughly to obtain a mixture;

[0046] S3, adding the mixture into a twin-screw extruder, and extruding it at a temperature of 200°C to ...

Embodiment 3

[0049] Biological filler structure is the same as embodiment one

[0050] The filler matrix includes the following raw materials in parts by weight: 50 parts of polypropylene, 40 parts of polyvinyl chloride, 18 parts of polyvinyl alcohol, 8 parts of polyacrylamide, 3 parts of antioxidant, and the antioxidant is a mass ratio of 1:0.05:0.8 A composition of molecular sieves, 2,6-di-tert-butyl-p-cresol and boron nitride;

[0051] The preparation method of filler matrix comprises the following steps:

[0052] S1. Molecular sieves, 2,6-di-tert-butyl-p-cresol and boron nitride are added to a fine grinder according to the mass ratio, and fully ground for 0.5h to obtain an antioxidant;

[0053] S2. Add the polypropylene, polyvinyl chloride, polyvinyl alcohol, polyacrylamide and antioxidant of the specific gravity into the high mixer, and mix thoroughly to obtain a mixture;

[0054] S3, adding the mixture into a twin-screw extruder, and extruding it at a temperature of 220° C. to form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com