Method for preparing one-dimensional luminescent ultrafine CsPbBr3 perovskite nano-wires

A perovskite and nanowire technology, applied in the field of nano-luminescent material preparation, can solve the problems of difficult to control reaction time nucleation rate, unsatisfactory product optical properties, low product comparability, etc., achieving excellent luminescent properties, less defects, Surface complete effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]A One-dimensional Luminescent Ultrafine CsPbBr 3 A method for preparing perovskite nanowires, comprising the following steps:

[0038] In a constant temperature water bath at 20°C, weigh 7.8g of acetone, 0.89g of oleic acid and 0.41g of oleylamine, add them into a 25mL three-neck flask with a condenser, stir until the reaction solution is clear and transparent, and accurately weigh 0.1468g of PbBr 2 and 0.0852g CsBr into a three-necked flask. at 2000r·min -1 centrifuged after 6 hours of reaction, the centrifuge speed is 6500r·min -1 , and the time is 5 minutes. After separation, the lower layer precipitated as the product CsPbBr 3 , the yield was 92%.

[0039] The present embodiment product CsPbBr 3 After drying in vacuum at 80°C, carry out XRD characterization, the results are as follows figure 1 shown by figure 1 Known embodiment 1 product is CsPbBr 3 .

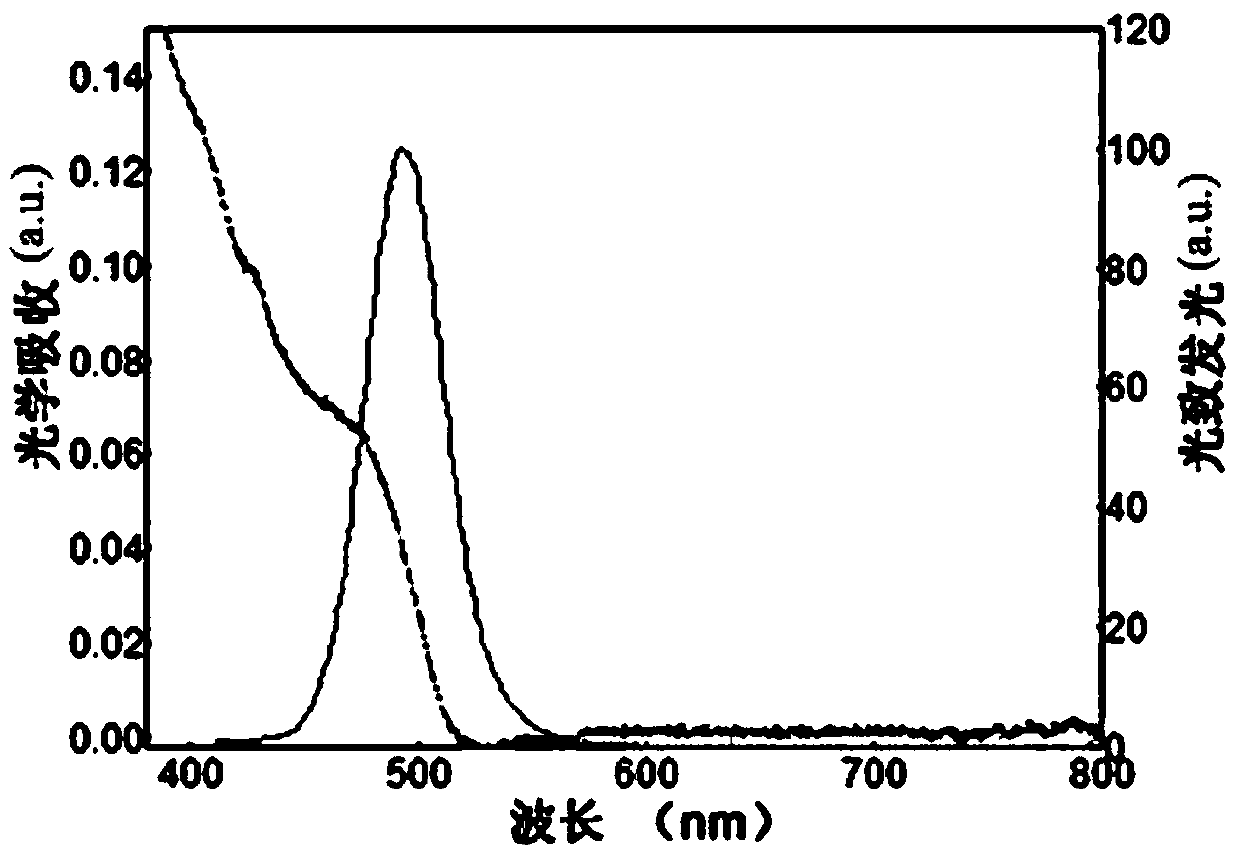

[0040] The present embodiment product CsPbBr 3 After being dispersed in toluene, it was characterized by...

Embodiment 2

[0043] A One-dimensional Luminescent Ultrafine CsPbBr 3 A method for preparing perovskite nanowires, comprising the following steps:

[0044] In a constant temperature water bath at 40°C, weigh 7.8g of acetone, 0.89g of oleic acid and 0.41g of oleylamine, add them into a 25mL three-neck flask with a condenser, stir until the reaction solution is clear and transparent, and accurately weigh 0.1468g of PbBr 2 and 0.0852g CsBr into a three-necked bottle. at 2000r·min -1 centrifuged after 4 hours of reaction, the centrifuge speed is 6500r min -1 , and the time is 5 minutes. After separation, the lower layer was precipitated to obtain the product CsPbBr 3 , and the yield was 87%.

[0045] The present embodiment product CsPbBr 3 After being dispersed in toluene, it was characterized by TEM, and its morphology features are as follows: Figure 5 shown by Figure 5 It can be seen that nanowires can be formed at this time, with a small amount of other morphological impurities, an...

Embodiment 3

[0047] A One-dimensional Luminescent Ultrafine CsPbBr 3 A method for preparing perovskite nanowires, comprising the following steps:

[0048] In a constant temperature water bath at 50°C, weigh 7.8g of acetone, 0.89g of oleic acid, and 0.41g of oleylamine, add them to a 25mL three-necked flask with a condenser, stir until the reaction solution is clear, and accurately weigh 0.1468g of PbBr 2 and 0.0852g CsBr into a three-necked bottle. at 2000r·min -1 centrifuged after 4 hours of reaction, the centrifuge speed is 6500r min -1 , and the time is 5 minutes. After separation, the lower layer was precipitated to obtain the product CsPbBr 3 , the yield was 80%.

[0049] The present embodiment product CsPbBr 3 After being dispersed in toluene, it was characterized by TEM, and its morphology features are as follows: Figure 6 shown by Figure 6 It can be seen that nanowires with uniform morphology can be formed at this time, with an average of 32.0 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com