Polycrystalline silicon reducing furnace

A reduction furnace, polysilicon technology, applied in the direction of silicon compounds, inorganic chemistry, non-metallic elements, etc., can solve the problems of uneven reaction temperature, affecting product quality, uneven material distribution, etc., to achieve uniform thickness and solve uneven reaction temperature. , the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

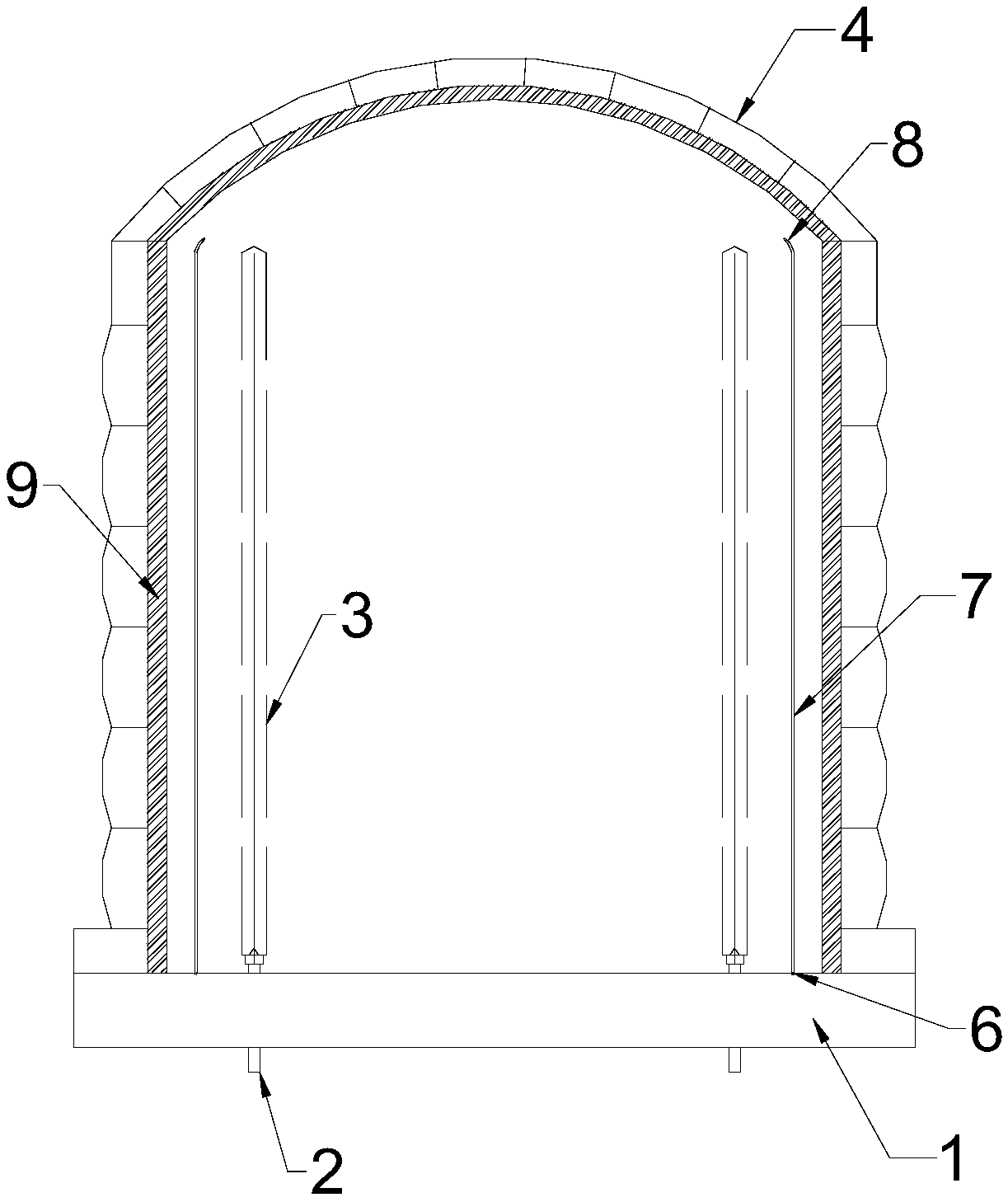

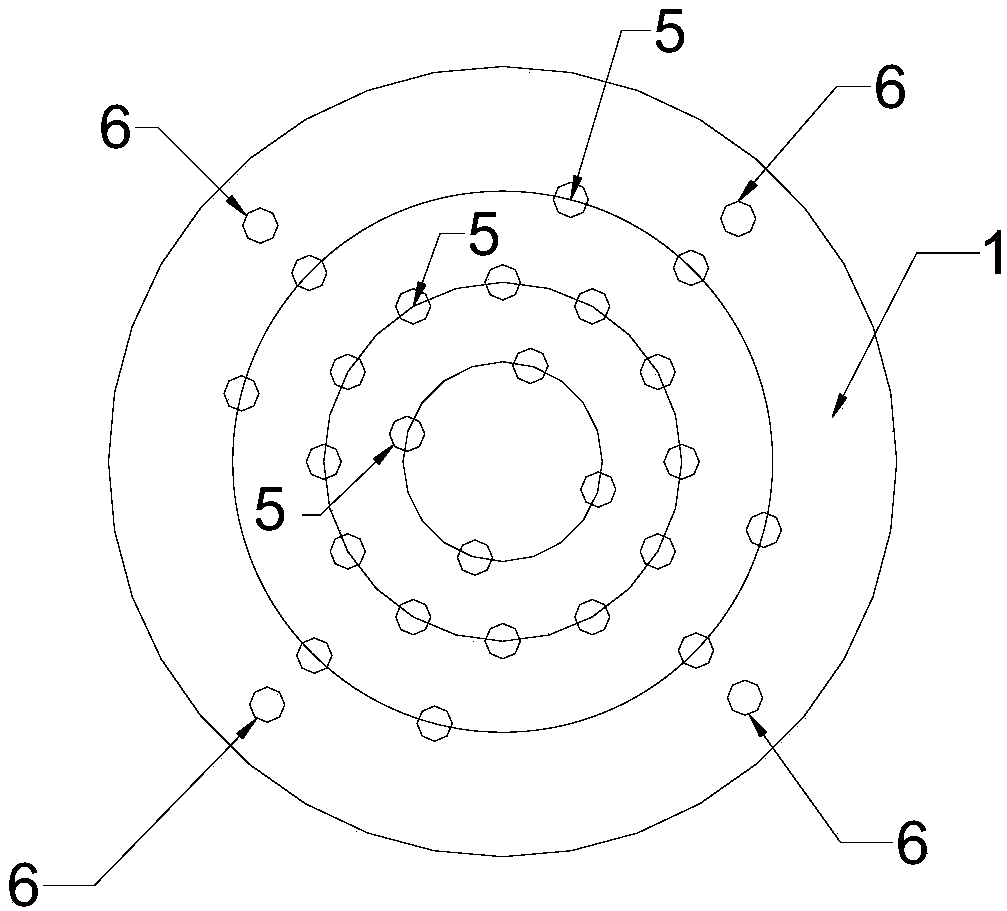

[0021] see figure 1 , figure 2 , the present invention provides a polysilicon reduction furnace, which includes a chassis 1, an electrode 2 arranged on the chassis 1 and a bell jar 4 placed above the chassis 1, silicon core rods 3 are installed on the electrodes 2, and the chassis 1 A plurality of bottom air inlet nozzles 5 are arranged on the top, and the bottom air inlet nozzles 5 are distributed in concentric circles on the chassis 1. Four top air inlets 6 are also arranged around the edge of the chassis 1, and the top air inlets 6 are preferably symmetrical. Equidistantly arranged around the edge of the chassis 1 , the top air inlet 6 is connected to the top air intake extension pipe 7 , and the top end of the top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com