Four-rope grab bucket slag material grabbing system

A technology of slag material and grab bucket, which is applied in the field of automatic control, can solve problems such as affecting sightlines and safety accidents, and achieve the effect of eliminating swing, heavy workload and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

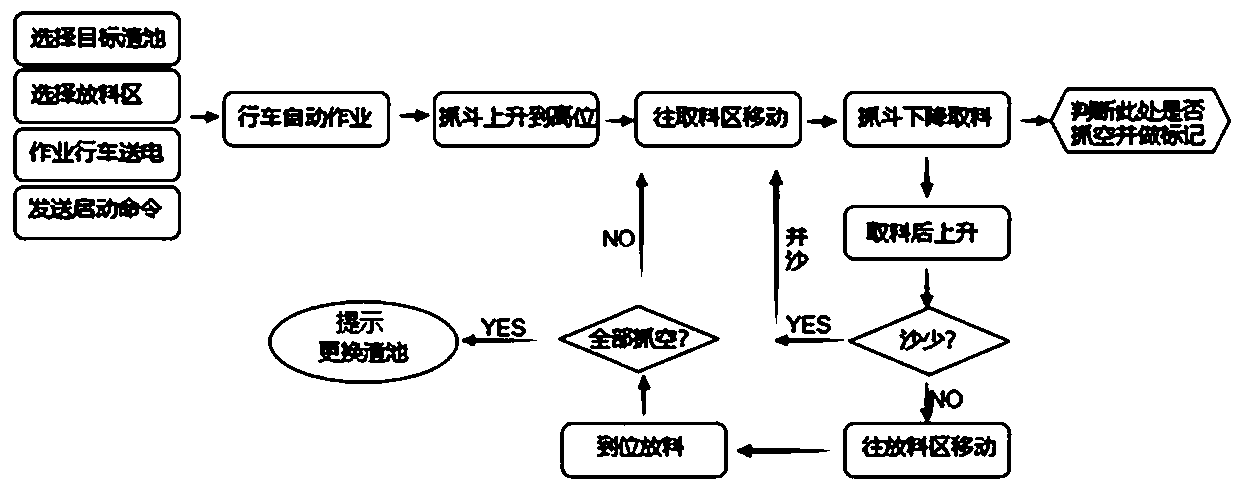

Method used

Image

Examples

Embodiment Construction

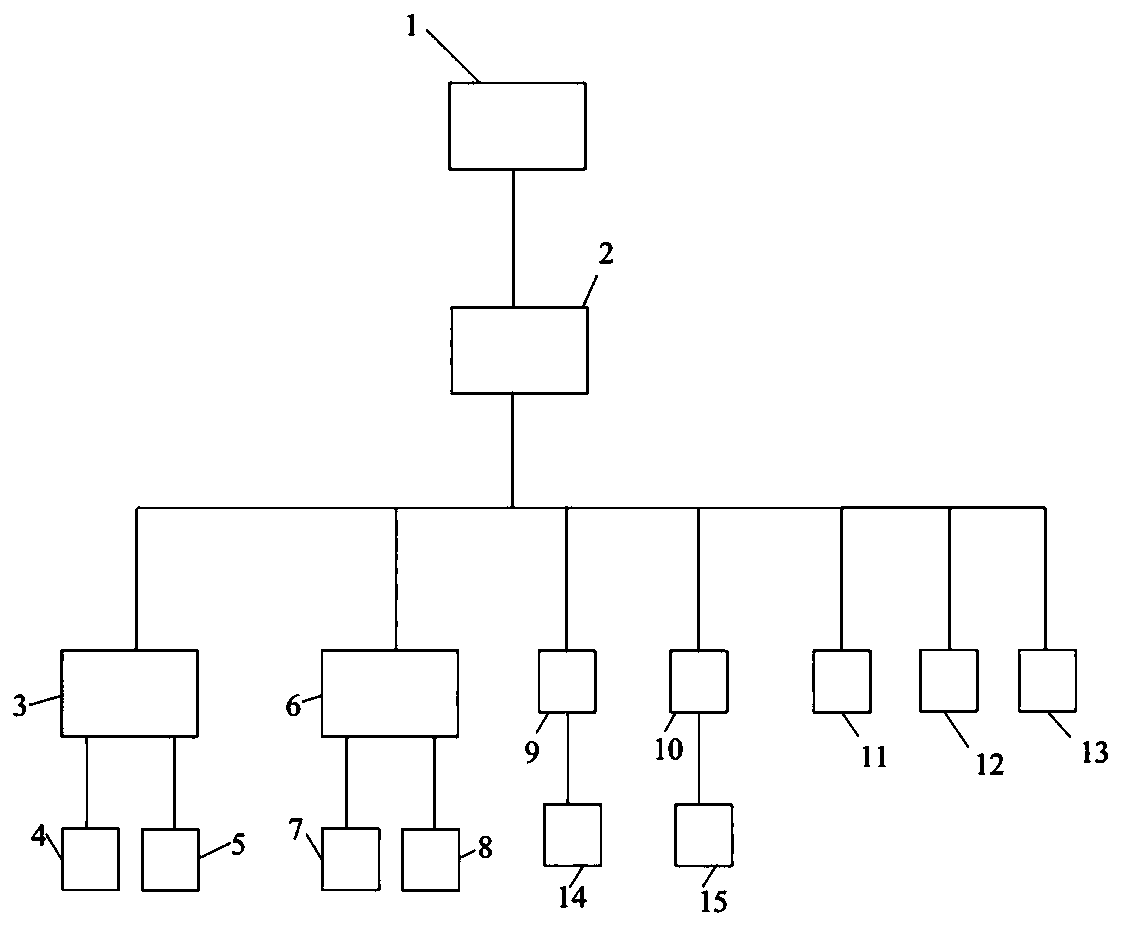

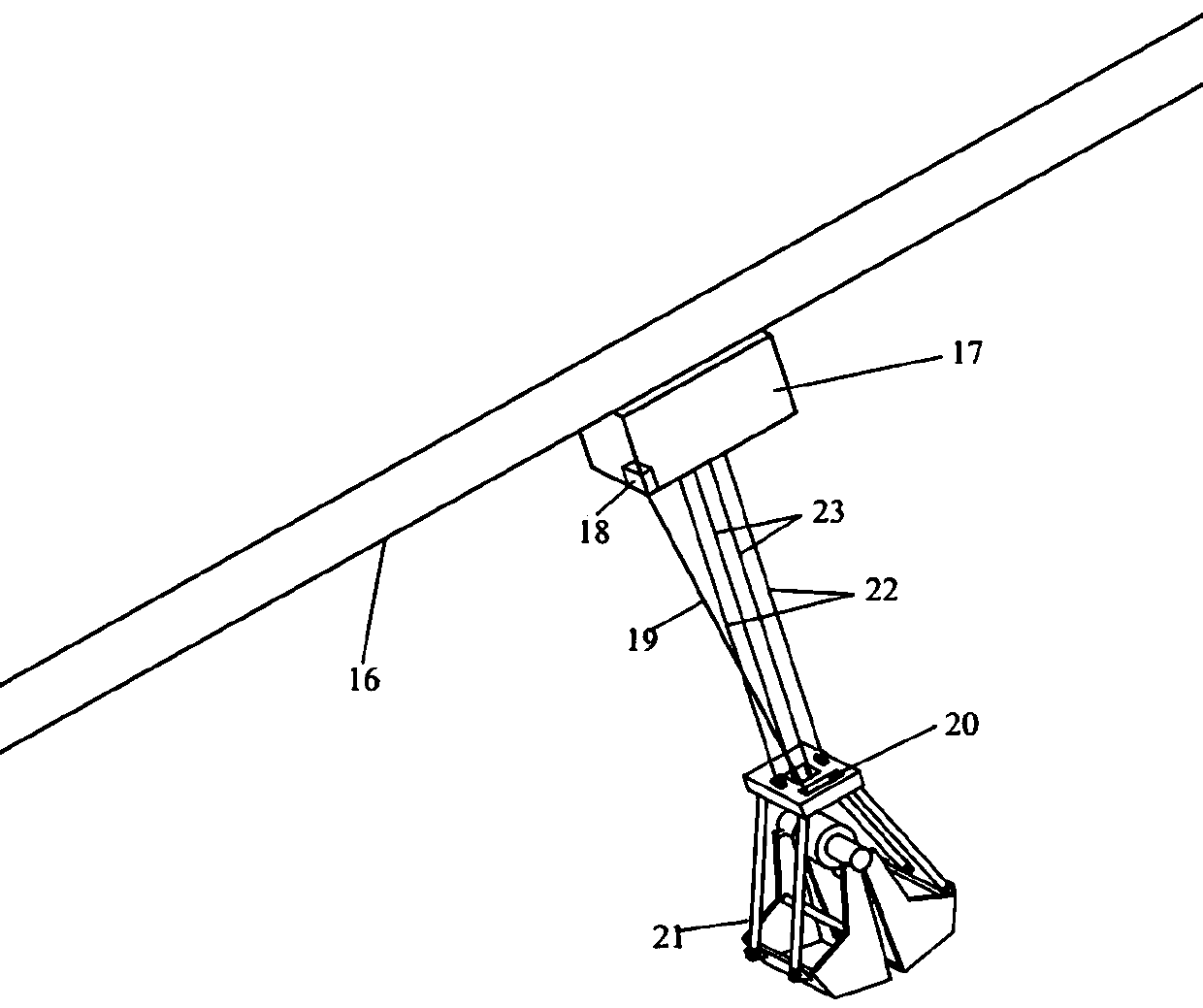

[0031] as attached Figure 2-5 As shown, the four-rope grab system provided by the present invention includes computer 1, PLC 2, lifting frequency converter 3, incremental encoder A5, switching frequency converter 6, incremental encoder B8, cart walking frequency conversion 9, trolley walking inverter 10, trolley positioning device 11, twisted rope detection device 12, overload limiter 13, cart traveling motor 14, trolley traveling motor 15, traveling girder 16, traveling trolley 17, grab bucket 21;

[0032] The driving trolley 17 is slidingly connected with the driving girder 16; the driving trolley 17 is provided with a lifting motor 4, an opening and closing motor 7, a hoisting rope 22, an opening and closing rope 23, a lifting drum 24, a limit cam 25, an opening and closing drum 26, Reducer A27 and reducer B36; hoisting motor 4 is connected with reducer A27, reducer A27 is connected with lifting drum 24; opening and closing motor 7 is connected with reducer B36, reducer B3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com