Improved sand-blasting machine

The technology of a sandblasting machine and a sandblasting device is applied in the field of machinery, which can solve the problems of affecting physical health, low sandblasting efficiency, increasing labor intensity of workers, etc., and achieves the effects of good sandblasting effect, high sandblasting efficiency and manpower saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

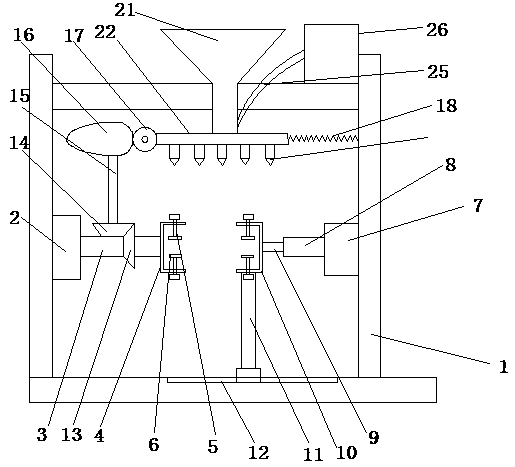

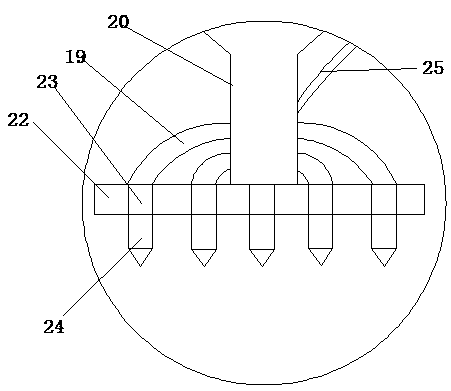

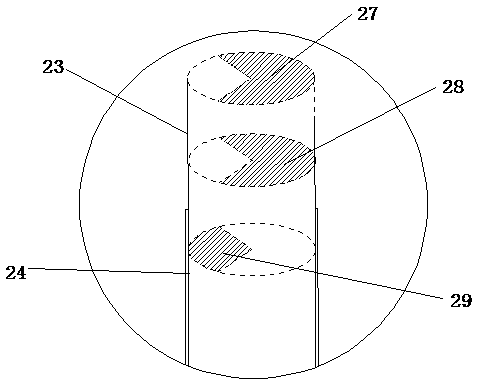

[0018] Such as Figure 1-Figure 3 An improved sand blasting machine shown includes a frame 1. The frame 1 is a rectangular structure with an upper end consisting of two side walls and a base. A motor 2 is fixedly installed in the side wall at the left end of the frame 1. The motor 2 Coaxially connected to the first rotating shaft 3, the other end of the first rotating shaft 3 is connected to the first guide sleeve 4, and the opposite side walls of the first guide sleeve 4 are provided with threaded holes, and the screw rod 5 extends into the first guide sleeve through the threaded hole 4, a splint 6 is fixedly installed at one end of the screw rod 5 inside the first guide sleeve 4. The right side of the frame 1 relative to the motor is equipped with a driving cylinder 7, the piston rod 8 of the driving cylinder 7 is connected with the rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com