Spraying paint exhaust gas adsorption treatment device

An adsorption treatment and waste gas technology, which is applied in gas treatment, dispersed particle filtration, membrane technology, etc., can solve the problem that the take-off pressure of the pressure relief valve cannot be adjusted according to the actual situation, the cost of activated carbon adsorbent is high, and the disassembly of the adsorption tank is inconvenient. Achieve the effect of reducing usage limitations, improving filtering effect, and improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

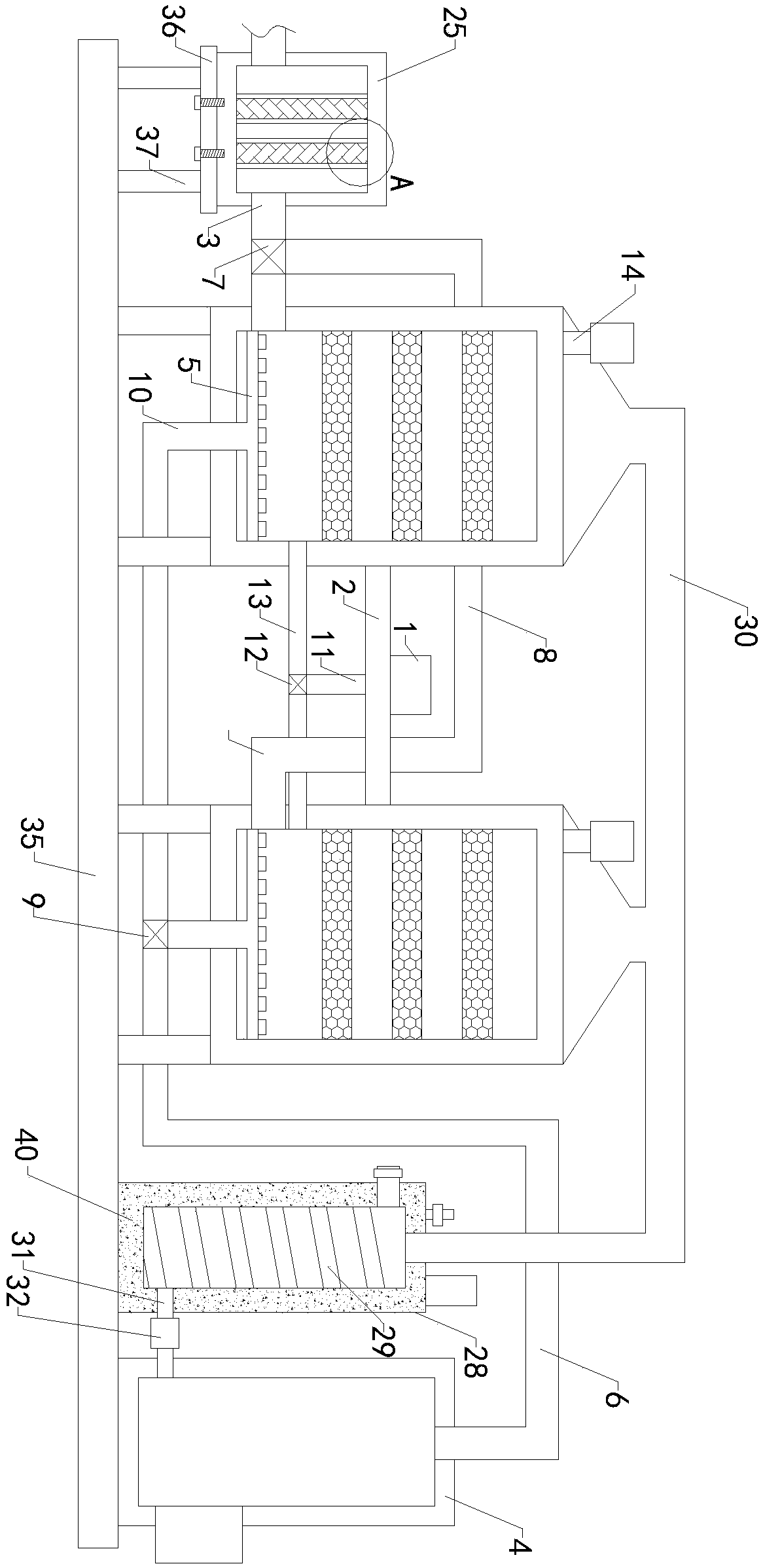

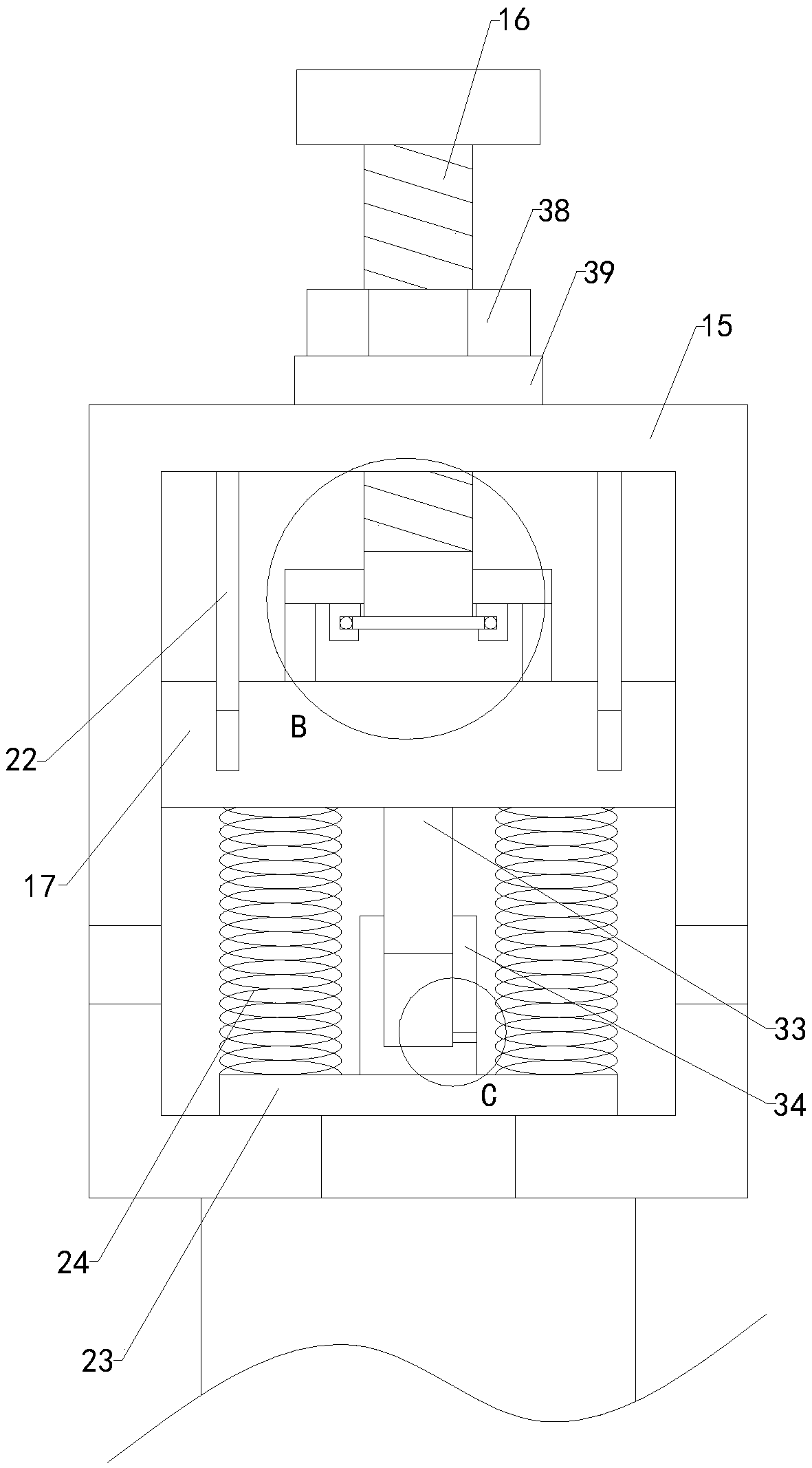

[0022] Such as Figure 1 to Figure 5 As shown, a kind of paint spray waste gas adsorption treatment device of the present invention comprises hot air blower 1, connecting plate 2, first connecting pipe 3, boiler 4, two groups of steam spray discs 5 and first steam pipeline 6, and adsorption tank is provided with two group, and the two groups of adsorption tanks are equipped with adsorption chambers, and the two groups of adsorption chambers are equipped with multiple sets of support screen frames horizontally, and the multiple sets of support screen frames inside the two groups of adsorption chambers are filled with multiple sets of activated carbon Adsorbent, the left fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com