Tobacco leaf baking controlling instrument

A control device and tobacco leaf technology, applied in the field of tobacco leaf control device and tobacco leaf curing control device, can solve the problems of poor tobacco leaf modulation, high relative energy consumption, motor heating, etc., so as to improve the quality of flue-cured tobacco, prolong the service life, and improve energy saving The effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

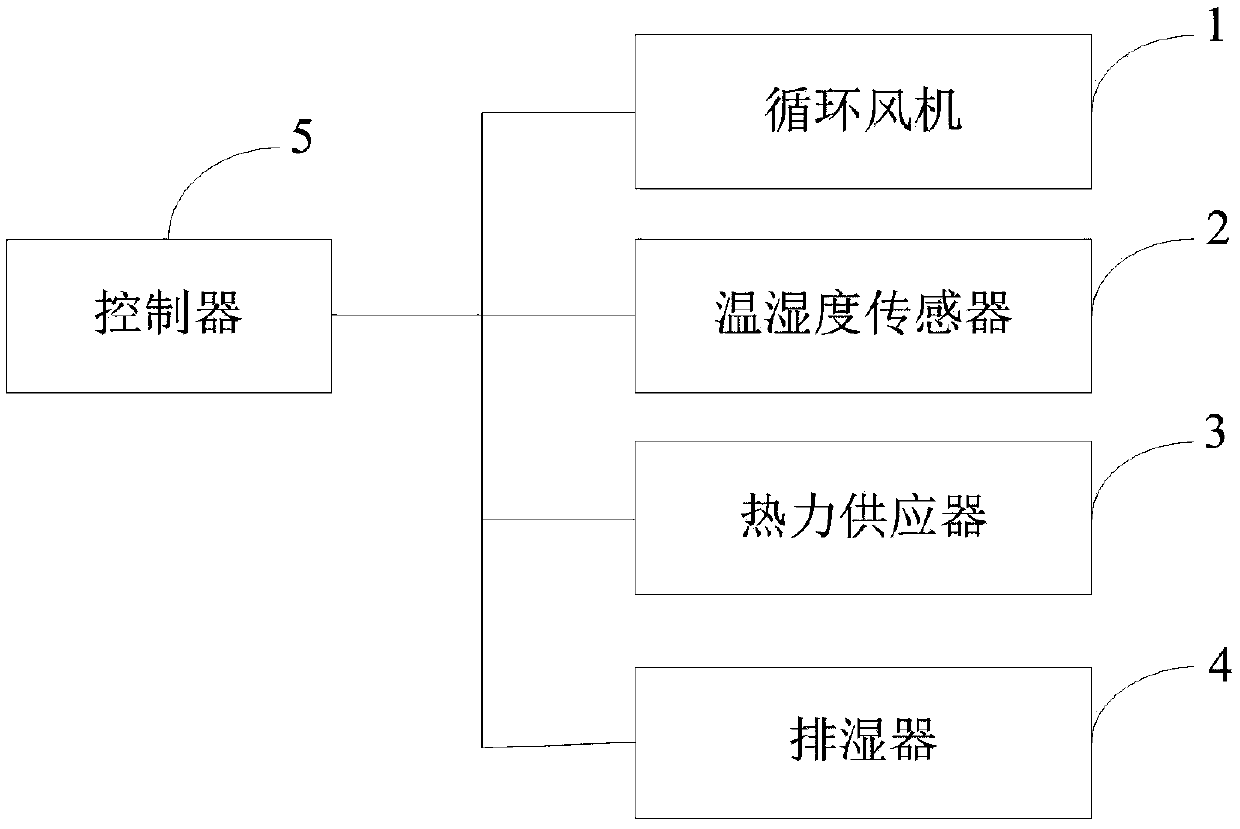

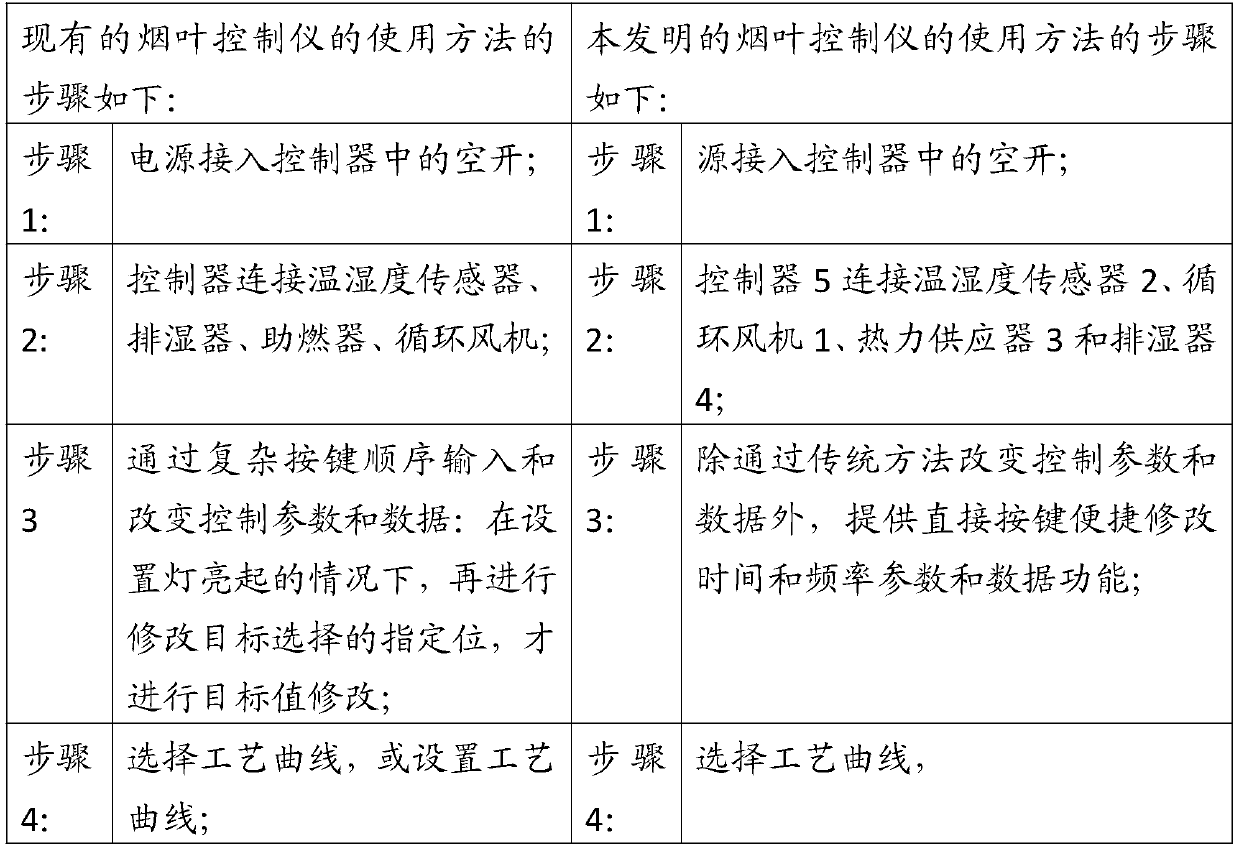

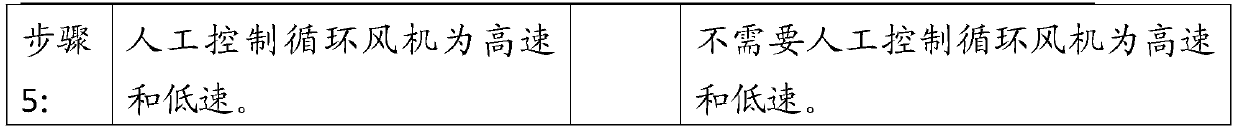

[0028] figure 1 It is a structural diagram of the tobacco leaf controller in the embodiment of the present invention. like figure 1 As shown, the tobacco leaf curing controller, the controller includes:

[0029] The circulation fan 1 is used to provide heat and air circulation for the smoke chamber;

[0030] The temperature and humidity sensor 2 is used to collect the temperature and humidity data of the smoke chamber to provide instruction basis for automatic control;

[0031] The heat supplier 3 is used to provide heat for the smoke chamber, and its heat is a necessary guarantee for biochemical reactions and dehydration;

[0032] Dehumidifier 4, used for dehumidification and dehydration of tobacco leaves;

[0033] The controller 5 is connected to the circulation fan, the temperature and humidity sensor, the heat supplier and the dehumidifier respectively, and is used to adjust the air and heat circulation speed and circulation direction in the smoke chamber respectively....

example 2

[0061] Because the speed adjustment of soft start is very wide, it can be set arbitrarily within 1 ~ 50Hz. The power changes of the 4 / 6-pole circulating fan and the permanent magnet circulating fan are respectively close to the following table 1 under the frequency conversion technology:

[0062] Table 1 Power consumption of 2.2kW permanent magnet or four-six-pole circulating fan working under the action of frequency converter (arbitrary adjustment)

[0063]

[0064] It can be seen from the above table 1 that soft start is beneficial to overcome the fragile equipment and reduce the starting current, especially to overcome the insufficient power supply of the full-load baking standby power generator set. It is good for saving energy and reducing consumption, improving intelligent control, reducing manual operation, and improving the quality of tobacco leaf curing. The inventor further compared the effects of the 4 / 6-pole fan and the permanent magnet frequency conversion fan...

Embodiment 3

[0066] In order to effectively prevent the biochemical change and physical change of the tobacco leaf process during the tobacco leaf preparation process, one-way bad direction conversion. The following test results have proved the advancement and creativity of the present invention.

[0067] Table 2 Statistical results and analysis table of dry and fresh tobacco leaves during curing (curing)

[0068]

[0069] As can be seen from Table 2, the impact on the dry matter of baking is: the weight gain of the lower leaf dry leaves is 5.3%, the middle part leaf dry leaf weight gain is 3.6%, and the upper leaf dry leaf weight gain is 1.9%.

[0070] Table 3 Overall appearance quality evaluation of cured tobacco leaves

[0071]

[0072]

[0073] Through the data in Table 3, the test group personnel and the tobacco farmers think together: the tobacco leaves after processing the curing of the present invention are good, the color is bright, the organizational structure of the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com