Non-contact type cable voltage measuring sensor

A voltage measurement, non-contact technology, applied in the field of sensors, can solve the problems of complex insulation structure, high-frequency oscillation of ferromagnetic resonance, inability to meet, etc., to ensure safety and convenience, eliminate magnetic saturation, and reduce insulation difficulty. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

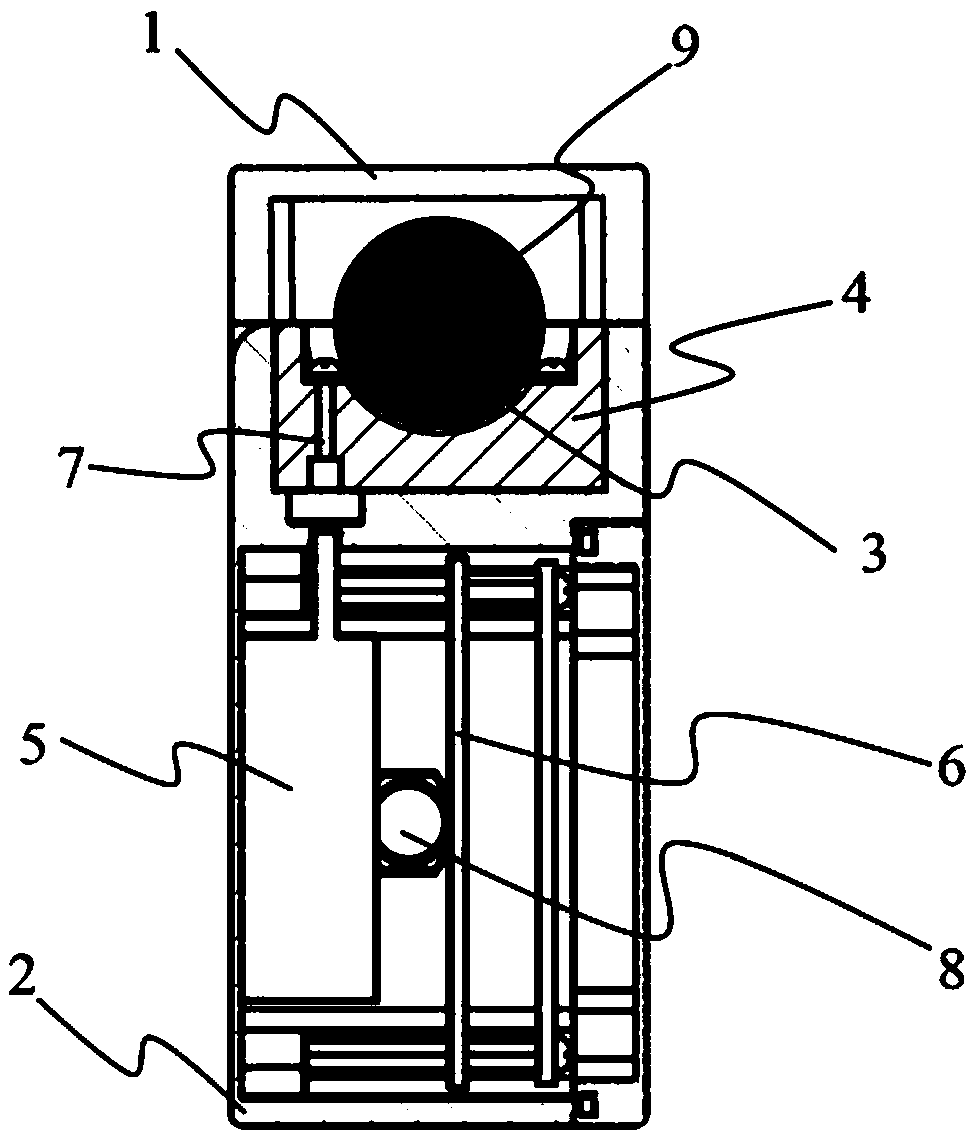

[0055] In the first exemplary embodiment of the present invention, a non-contact cable voltage measurement sensor is provided. figure 1 It is a schematic diagram of the cross-sectional structure of the non-contact cable voltage measurement sensor perpendicular to the cable axis direction according to the first embodiment of the present invention. Such as figure 1 As shown, the non-contact cable voltage measurement sensor of the present invention includes: a shielding cover 1, a housing 2, a detection electrode 3, an insulator 4, an electric field measurement module 5, a signal demodulation and communication circuit 6, an electrode wire 7 and an aviation Insert the female seat 8.

[0056] The shielding cover 1 is connected with the housing 2 to form a cavity structure. The cable 9 to be tested is inserted through the cavity structure. The shielding cover 1 can shield the influence of the external electric field on the cable to be tested 9 and make the voltage measurement accurate ...

no. 2 example

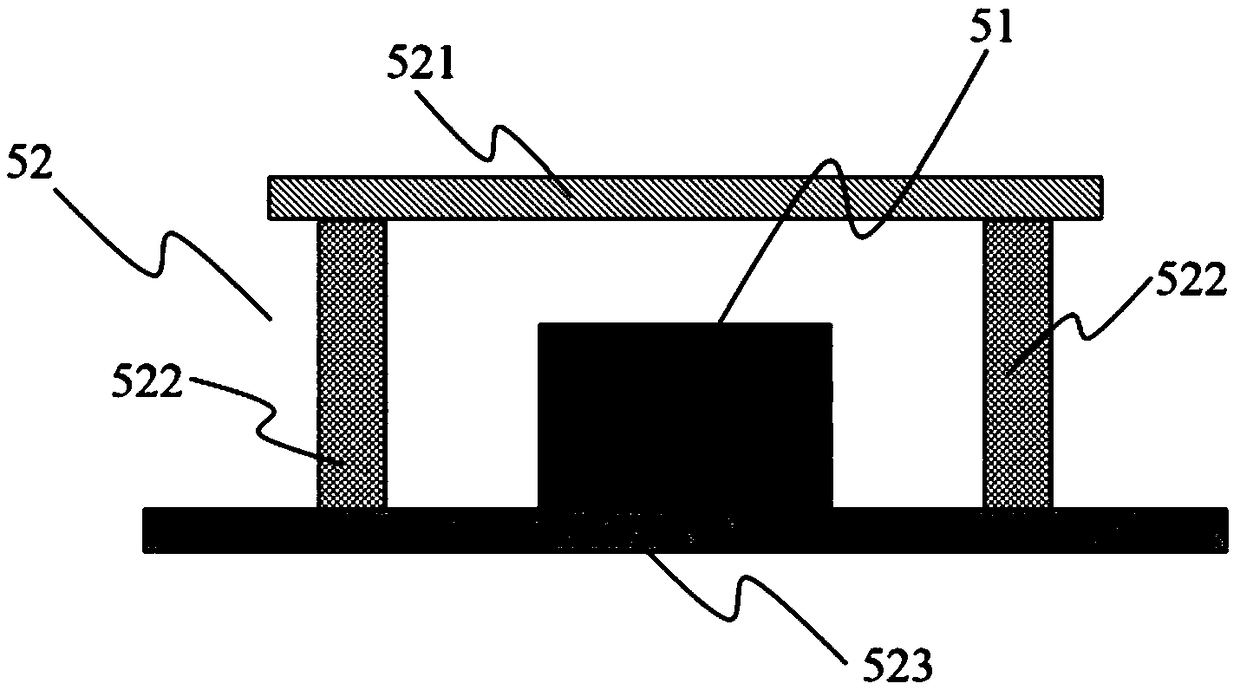

[0070] In the second exemplary embodiment of the present invention, a non-contact cable voltage measurement sensor is provided. Figure 5 It is a schematic cross-sectional view of a part of the structure perpendicular to the cable axis direction of the second embodiment of the present invention. Such as Figure 5 As shown, compared with the non-contact cable voltage measurement sensor of the first embodiment, the difference of the non-contact cable voltage measurement sensor of this embodiment is:

[0071] An insulating layer 10 is provided on the upper surface of the detection electrode 3 to completely cover the cable 9 under test. When the cable 9 under test is circular, the outer shape of the insulating layer 10 is circular, and its inner diameter is greater than or equal to the outer diameter of the cable 9 under test. Of course, the insulating layer 10 can also be partially connected to the detection electrode 3, and the other part is connected to the inside of the rotating ...

no. 3 example

[0075] In the third exemplary embodiment of the present invention, a non-contact cable voltage measurement sensor group is provided. Image 6 It is a schematic cross-sectional view of a part of the structure perpendicular to the cable axis direction of the third embodiment of the present invention. Such as Image 6 As shown, the non-contact cable voltage measurement sensor group of the present invention includes three non-contact cable voltage measurement sensors, and each non-contact cable voltage measurement sensor is the same as the non-contact cable voltage measurement in the second embodiment. The structure of the sensors is the same, but the thickness of the insulating layer 10 in each non-contact cable voltage measurement sensor is not consistent.

[0076] Using multiple non-contact cable voltage measurement sensors to measure the voltage of high-voltage cables can eliminate common mode interference noise and further improve measurement accuracy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com