Sand-coated sound absorption board based on gypsum board

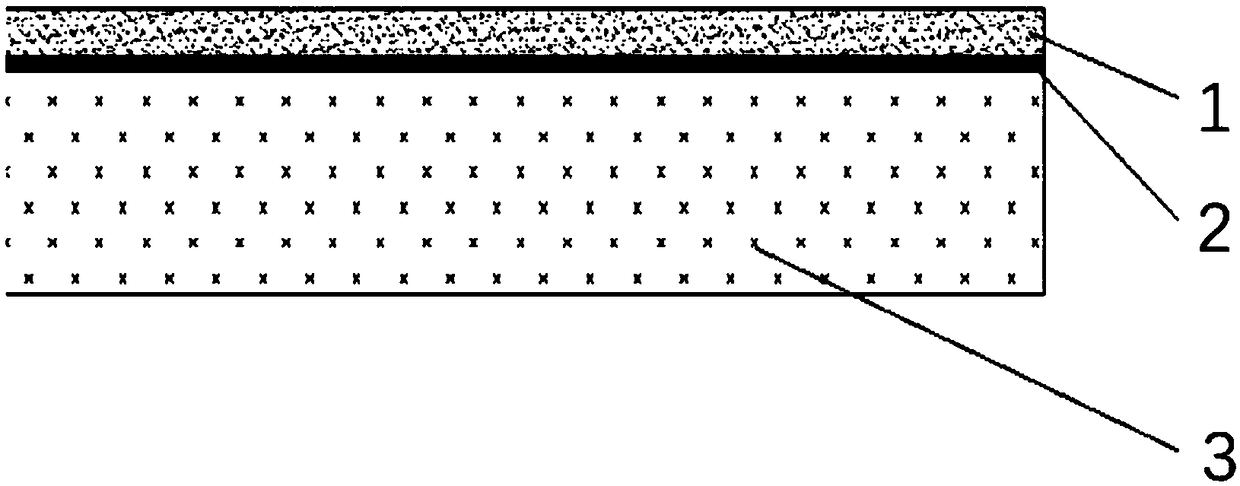

A technology of gypsum board and sound-absorbing board, which is applied in the direction of covering/lining, layered products, construction, etc. It can solve the problems that the sound-absorbing characteristics cannot be customized and adjusted, the flame-retardant performance of sound-absorbing materials is low, and the large-area cannot be realized, so as to achieve improvement Good sound insulation performance, good sound absorption performance, and excellent sound absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] Preferably, the above-mentioned sand-covered sound-absorbing board based on gypsum board, the preparation method of the resin particles includes:

[0031] Add fiber mixed with calcium carbonate to the resin before the resin is cured, and decompose the calcium carbonate under acidic conditions after the resin is cured;

[0032] Wherein, the fiber mixed with calcium carbonate is preferably added in the form of a grid braid, and is evenly immersed in the resin before the resin is solidified. The grid braids of different layers can be tightened to form a fixed interval, and the solidified Calcium carbonate fibers are mixed into the resin; before the calcium carbonate is decomposed and decomposed under acidic conditions, the resin can be crushed into predetermined small particles (or granulated), and the acid can penetrate through the fiber material on the surface of the resin. inside the resin, and dissolve the calcium carbonate, the CO produced by the reaction 2 It can be...

Embodiment 1

[0055] In this embodiment, a method for preparing a sand-covered sound-absorbing board based on gypsum boards includes:

[0056] a. Preparation of inorganic binder: add (by weight) 7 parts of sodium silicate, 5 parts of magnesium silicate, and 1 part of lithium silicate to 12 parts of water to obtain water glass;

[0057] b. Preparation of resin particles:

[0058] Add 20 parts of calcium carbonate fibers / nanoparticles and 80 parts of polylactic acid into the screw extruder with the required composite width nozzle, at 2.66×10 -3Vacuum under Pa, under the protection of nitrogen, melt and mix evenly at 179°C-200°C, spin it through the spinning head at a speed of about 0.5m / min and cool to a temperature of about 20°C. The diameter of the fiber is 0.1 mm to 0.2 mm. The obtained fiber that is mixed with calcium carbonate is woven into a grid shape, divided into 2 layers and evenly placed in the mold (the addition accounts for 30% of the resin volume after curing), and slowly impo...

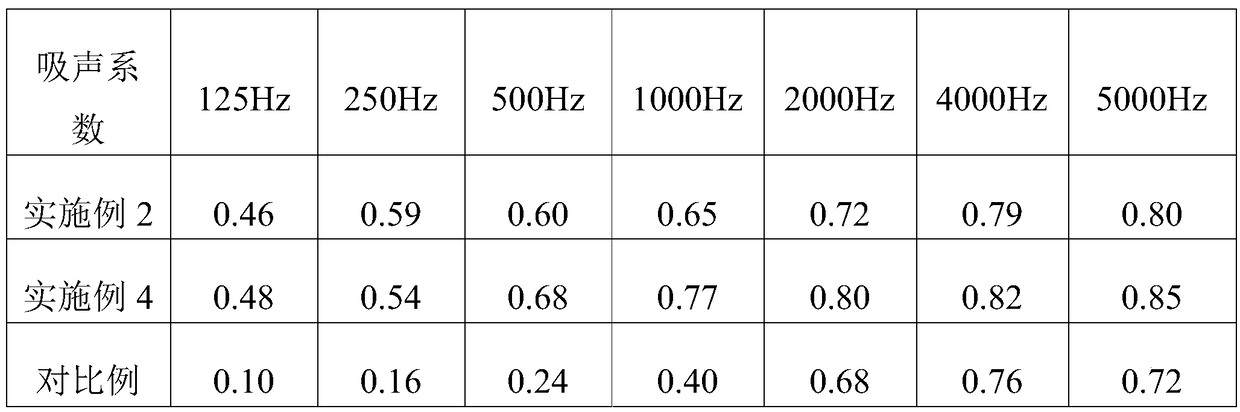

Embodiment 2

[0065] In this embodiment, a method for preparing a sand-covered sound-absorbing board based on gypsum boards includes:

[0066] a. Preparation of inorganic binder: 13 parts by weight of sodium silicate, 1 part of magnesium silicate, 3 parts of lithium silicate were added to 18 parts of water to obtain water glass;

[0067] b. Preparation of resin particles:

[0068] Add 40 parts of calcium carbonate fiber / nanoparticles and 60 parts of polylactic acid into the screw extruder with the required composite width nozzle, at 2.66×10 -3 Vacuum under Pa, under the protection of nitrogen, melt and mix evenly at 179°C-200°C, spin it through the spinning head at a speed of about 0.5m / min and cool to a temperature of about 20°C. The diameter of the fiber is 0.1 mm to 0.2 mm. The obtained fiber mixed with calcium carbonate is woven into a grid shape, divided into 3 layers and placed evenly in the mold (the addition accounts for 40% of the resin volume after curing), slowly import epoxy r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com