Orthotropic steel-ultra high performance concrete bridge deck structure and its construction method

An ultra-high-performance, orthotropic technology, applied in bridges, bridge materials, bridge construction, etc., can solve problems such as roof and longitudinal ribs, longitudinal ribs and diaphragm fatigue cracking, etc., to achieve fatigue cracking, reliable connection, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

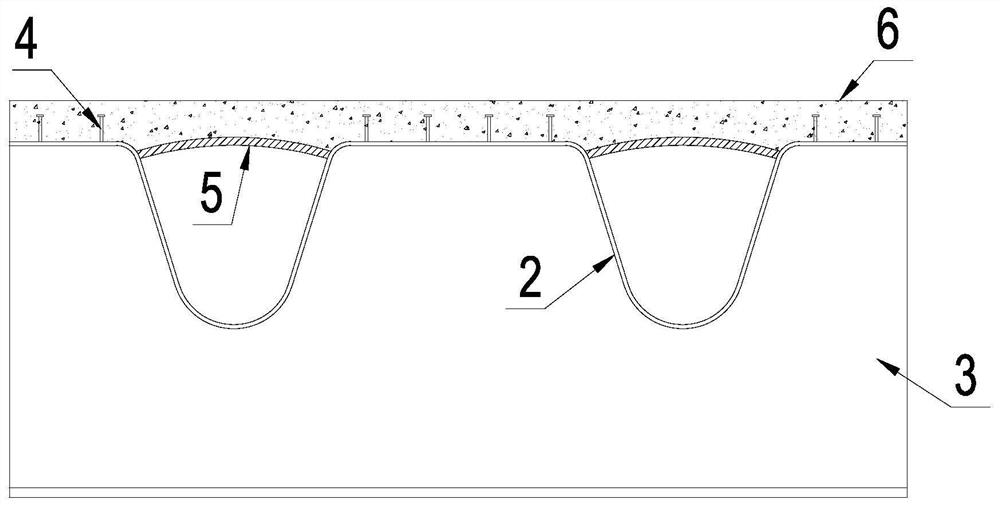

[0043] Such as figure 2 As shown, the prefabricated ultra-high-performance concrete layer 5 is arranged in the upper notch of the U-shaped groove, and the cast-in-place ultra-high-performance concrete layer 6 is arranged above the prefabricated ultra-high-performance concrete layer 5 and covers the top of the longitudinal rib 2 face. During the construction process, firstly, a prefabricated ultra-high performance concrete layer 5 is placed in the U-shaped notch as a base form, and the ultra-high performance concrete layer 6 is formed by pouring again.

specific Embodiment 2

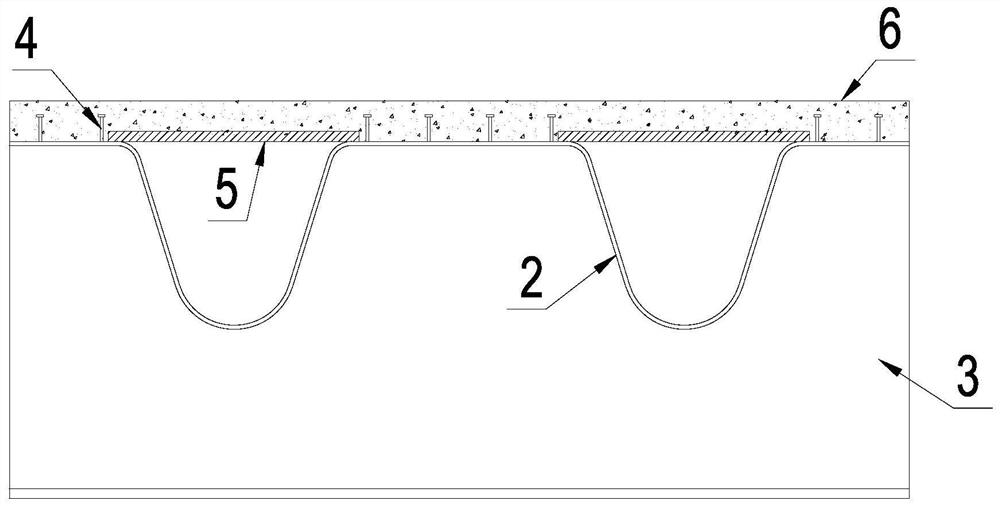

[0045] Such as image 3 As shown, the structure of its ultra-high performance concrete bridge deck 1, longitudinal rib 2, diaphragm 3 and shear connector 4 is the same as that of the specific embodiment 1, the difference is that the prefabricated ultra-high performance concrete layer 5 is a slab shape, and its bottom surface is flush with the upper end surface of the U-shaped notch.

specific Embodiment 3

[0047] Such as Figure 4 As shown, the prefabricated ultra-high performance concrete layer 5 is set on the top of the U-shaped groove, and the cast-in-place ultra-high performance concrete layer 6 is set on both sides of the prefabricated ultra-high performance concrete layer 5, and its top surface is the same as the prefabricated ultra-high performance concrete layer. The top surface of the concrete layer 5 is flush.

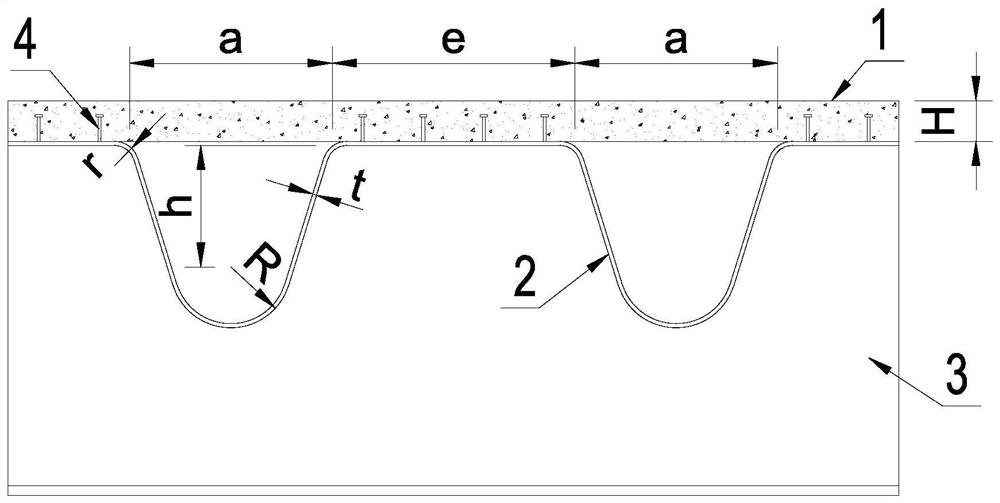

[0048]In the present invention, in order to increase the strength, several steel bars are embedded in the ultra-high performance concrete bridge deck 1 and arranged in a net shape. Preferably, the thickness H of the ultra-high performance concrete bridge deck 1 is 8-15 cm. Between the U-shaped grooves on the longitudinal ribs 2 is a horizontal part, the bottom of the U-shaped grooves is arc-shaped, and the notches are connected to the horizontal parts of the longitudinal ribs 2 through arc chamfering. Preferably, the notch width a of the U-shaped groove is 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com