Formaldehyde recycling device

A formaldehyde and absorption tower technology, applied in the field of formaldehyde recovery devices, can solve problems such as increasing product consumption, formaldehyde product waste, etc., and achieve the effects of reducing unit consumption, solving pipeline blockage, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

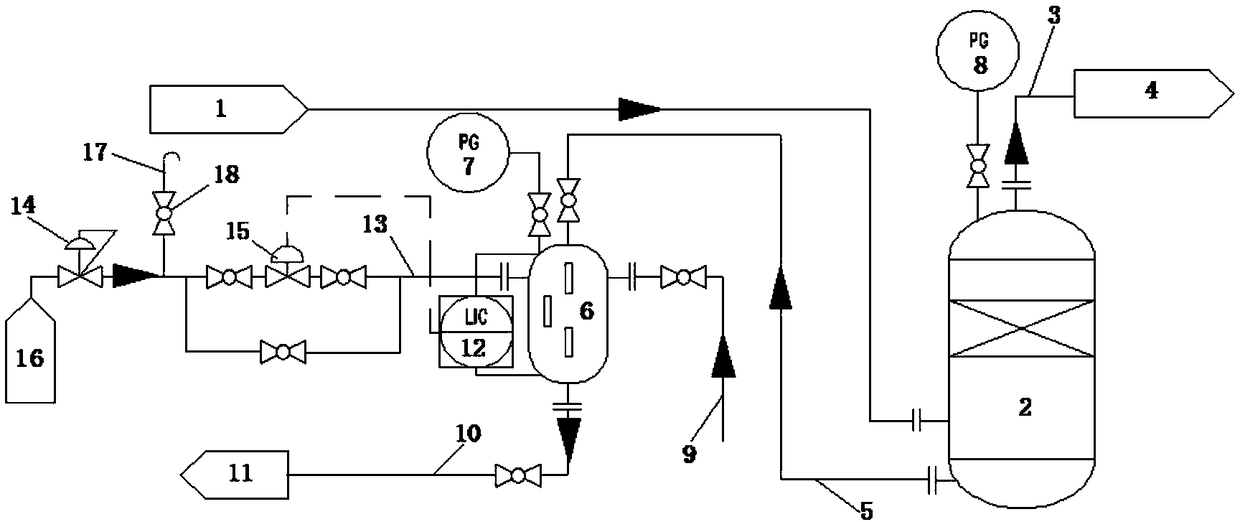

[0020] When the amount of methanol in the formaldehyde reactor is 4000kg / h, the amount of water added to the top of the formaldehyde absorption tower is 800kg / h, the formaldehyde content in the tail gas at the top of the tower is 0.08%, and the total amount entering the tail gas eliminator 2 is 9000Nm 3 / h, the amount of tail gas recovered by the reactor is 3600Nm 3 / h, the recovery system of this device completes a condensate delivery process every 4 hours in the condensate tank 6, and 1.8m of condensate can be recovered throughout the day 3 , equivalent to about 15kg of 100% formaldehyde.

Embodiment 2

[0022] When the amount of methanol in the formaldehyde reactor is 3000kg / h, the amount of water added to the top of the formaldehyde absorption tower is 600kg / h, the formaldehyde content in the tail gas at the top of the tower is 0.07%, and the total amount entering the tail gas eliminator 2 is 6500Nm 3 / h, the amount of tail gas recovered by the reactor is 2700Nm 3 / h, the recovery system of this device completes a condensate delivery process every 5 hours in the condensate tank 6, and 1.4m of condensate can be recovered throughout the day 3 , equivalent to about 10kg of 100% formaldehyde.

Embodiment 3

[0024] When the amount of methanol in the formaldehyde reactor is 2500kg / h, the amount of water added to the top of the formaldehyde absorption tower is 450kg / h, the formaldehyde content in the tail gas at the top of the tower is 0.06%, and the total amount entering the tail gas eliminator 2 is 5500Nm 3 / h, the amount of tail gas recovered by the reactor is 2200Nm 3 / h, the recovery system of this device completes a condensate delivery process every 6 hours in the condensate tank 6, and 1.2m of condensate can be recovered throughout the day 3 , equivalent to about 5kg of 100% formaldehyde.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com