System used for solar battery cell printing and printing method

A technology of solar cells and printing methods, which is applied in the post-processing of printing, general parts of printing machinery, printing, etc., can solve the problems of poor transfer printing effect, poor quality, and poor printing uniformity, and achieve good transfer printing effect, High yield rate and good printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the drawings and specific embodiments of the specification.

[0035] At present, the main application formats for printing are relief, offset, and intaglio. The existing common intaglio printing is characterized by concave parts of the graphics and text, so that the layout is completely immersed in the printing material, and then the excess printing material is scraped off with a squeegee to remove the remaining concave The method of transferring the lower part of the printed material to the printed matter is gravure printing. This solution uses conductive silver paste as a printing material for printing on solar cells. The printed matter has a three-dimensional effect, and the small lines can be printed clearly, so that various plates can be freely and widely selected and used.

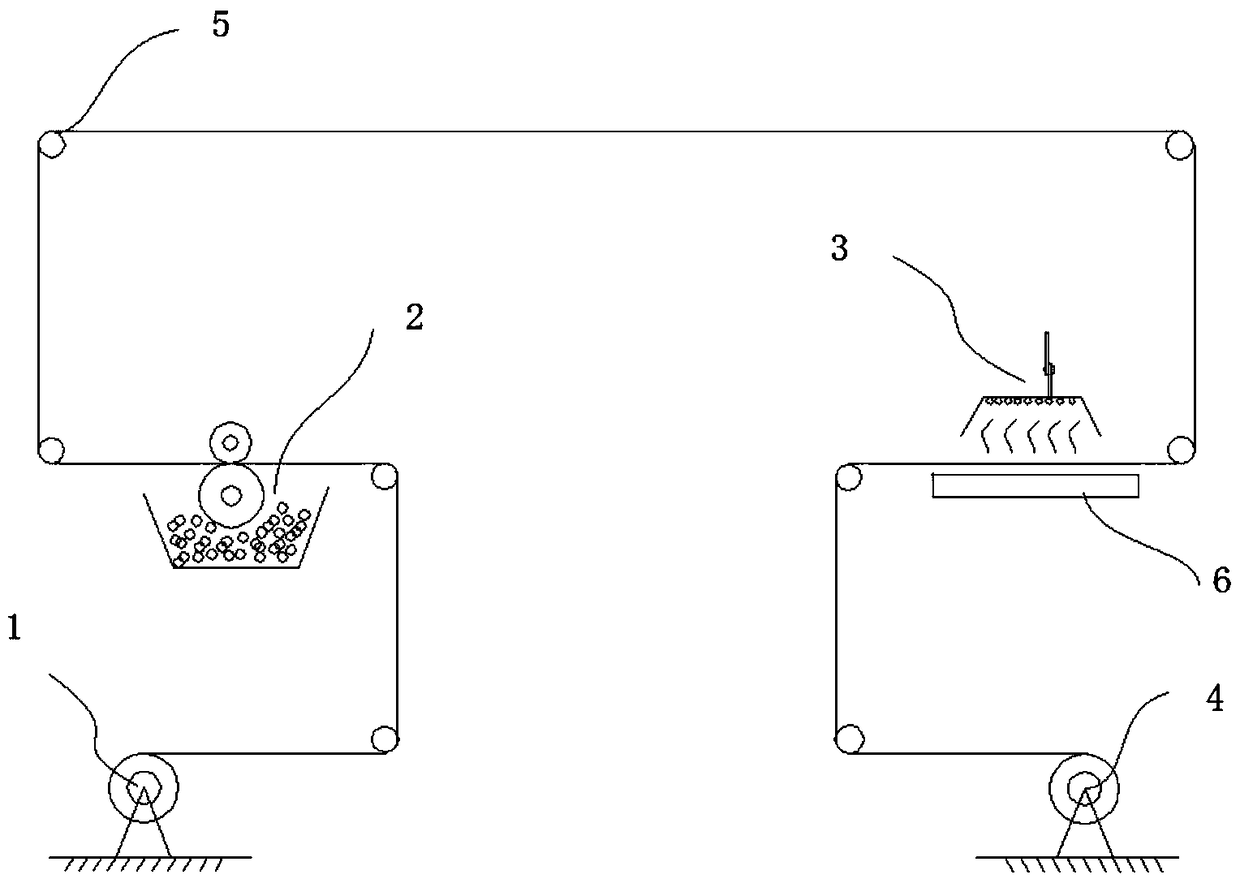

[0036] Such as figure 1 As shown, this solution establishes a system for screen printing to print the substrate 1 of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com