A warm isostatic press

A technology of warm isostatic pressing machine and pressing plate, which is applied in presses, manufacturing tools, etc. It can solve the problems of large heat absorption, rapid temperature drop of pressure transmission medium, and inability to maintain a constant temperature in the cylinder, so as to prevent damage, big drive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

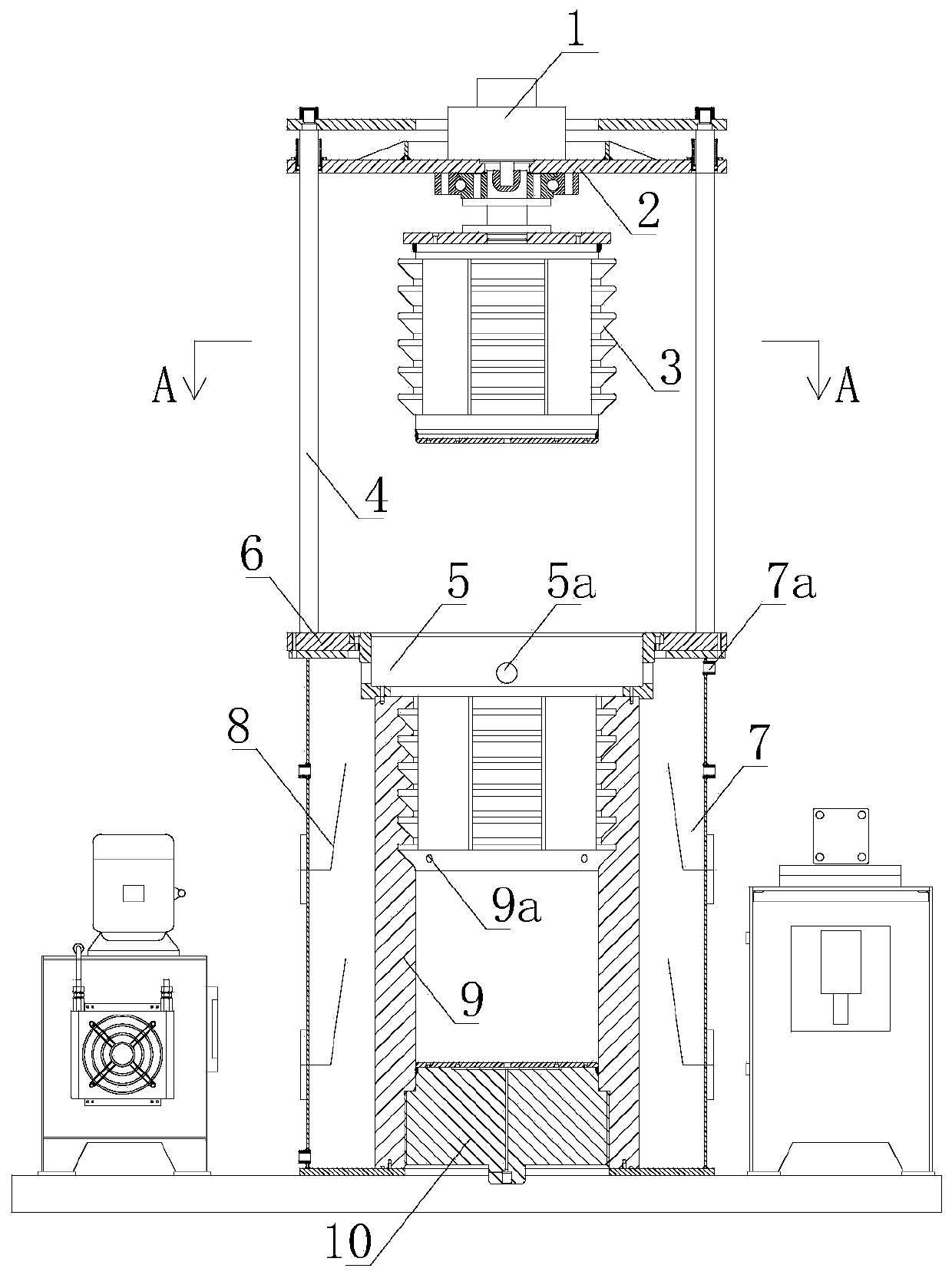

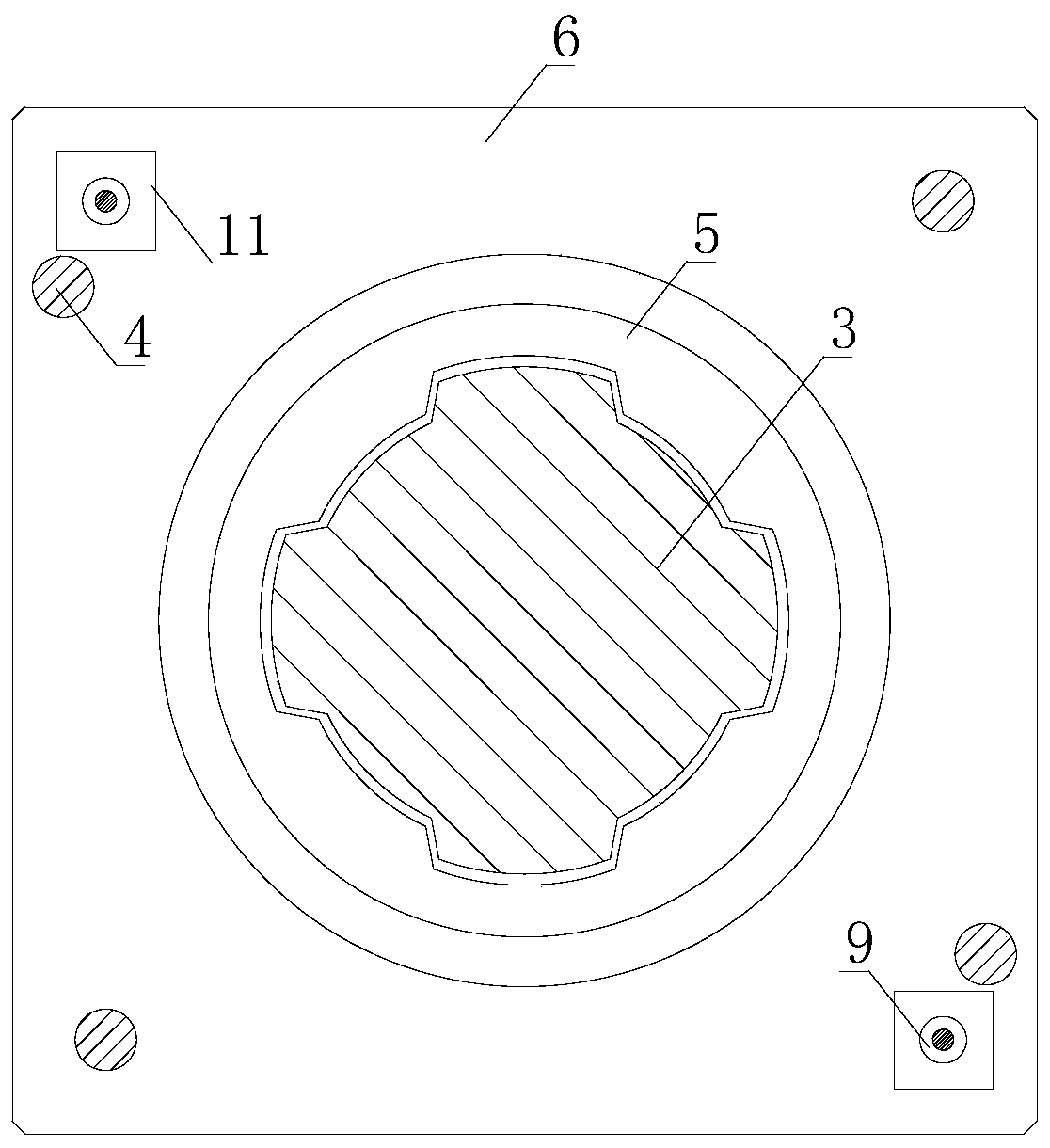

[0035] Such as Figure 1-9 As shown, this embodiment provides a warm isostatic press, including a heating filling system, a working cylinder and an incubator 7; the heating filling system is respectively provided with an inlet and an outlet, and the inlet of the heating filling system is connected to There is a water tank; the working cylinder includes a hollow cylinder body 9 with openings at both ends of the upper and lower ends and an upper end cover assembly 3 and a lower end cover assembly 10 which are respectively sealed at the openings at both ends of the cylinder body 9; When the inner wall is provided with a drainage hole 9a and the upper end cover assembly 3 blocks the cylinder body 9, the drainage hole 9a is also blocked by the upper end cover assembly 3; The outlet of the row system and the channel 10e of the hollow part of the cylinder 9; the insulated box 7 is set outside the cylinder 9 and has a gap with the cylinder 9, and the top of the insulated box 7 is prov...

Embodiment 2

[0042] For implementing the present invention better, on the basis of embodiment 1, as Figure 1-9 As shown, in this example,

[0043] The warm isostatic press also includes a bottom plate 6, a lifting plate 2 that slides up and down on the bottom plate 6, a first driving device 11 that drives the lifting plate 2 to slide up and down, and a The second driving device 1; a rotary locking structure is provided between the upper end cover assembly 3 and the cylinder body 9, and the upper end cover assembly 3 is rotatably arranged on the lifting plate 2; the second driving device 1 drives the upper end cover assembly 3 Forward and reverse.

[0044] By providing the first driving device 11 and the second driving device 1 , the labor intensity of the operator can be reduced. Preferably, in this embodiment, the first driving device 11 includes an oil cylinder, and the second driving device 1 includes a hydraulic motor. Specifically, such as Figure 1-2 As shown, in this embodiment...

Embodiment 3

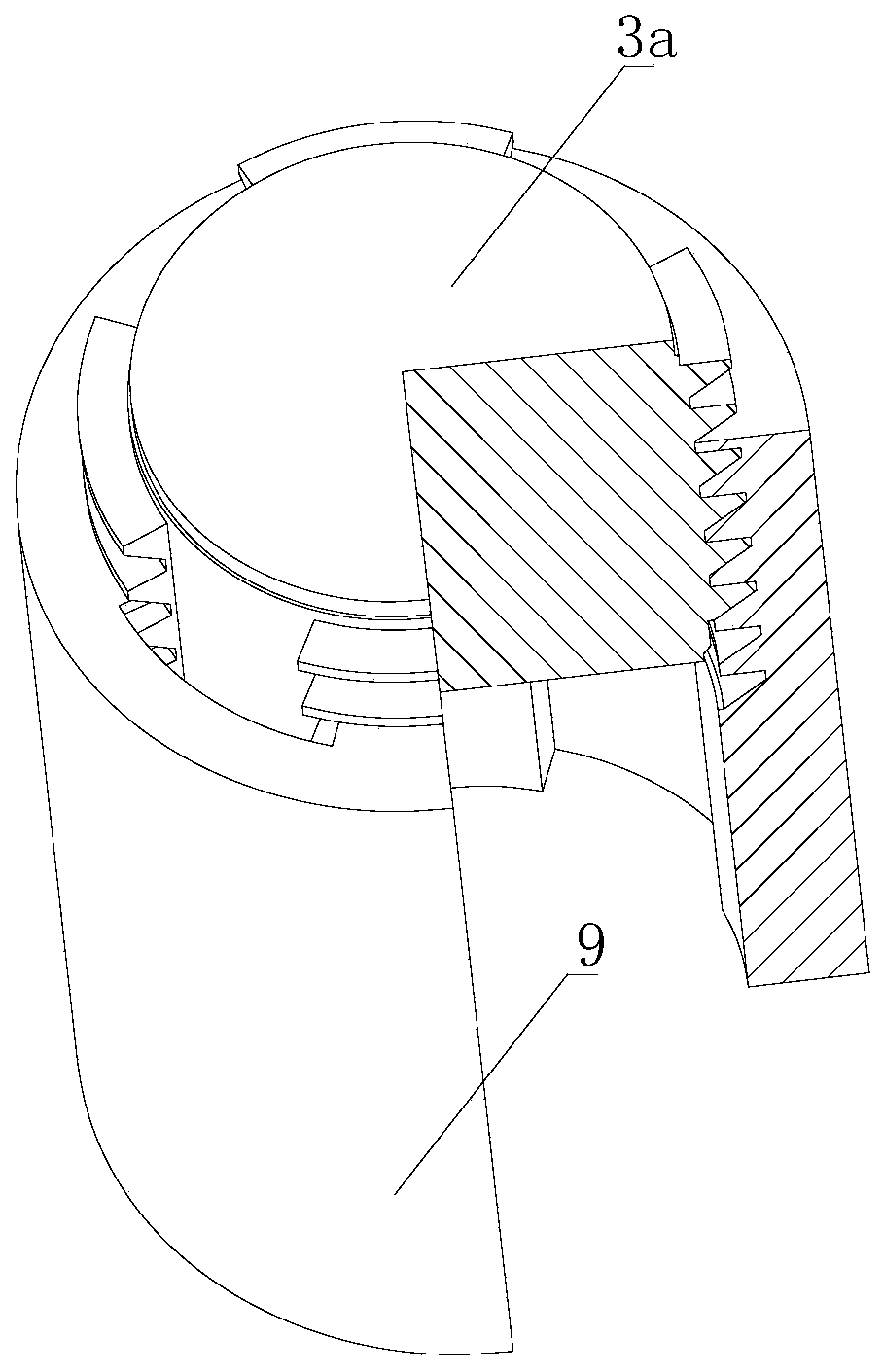

[0047] For implementing the present invention better, on the basis of embodiment 1, as Figure 1-9 As shown, in this embodiment, the upper end cover assembly 3 includes a locking member 3a, a first sealing retaining ring 3f, a first sealing ring 3d, a second sealing ring 3g and a lower pressure plate 3e; the locking member 3a and the A rotary locking structure is provided between the cylinders 9; the bottom end of the locking member 3a is provided with a first circular platform section and a first cylindrical section sequentially connected from top to bottom; The diameter of the small end of a circular platform section is equal to the diameter of the first cylindrical section; the inner surface of the first sealing retaining ring 3f is an inner conical surface adapted to the first circular platform section; the lower pressure plate 3e is detachably connected to the first cylindrical section On the bottom end face; the first sealing ring 3d is arranged on the top of the locking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com