Centering guide mechanism of pipe die washing machine

A technology of guiding mechanism and cleaning machine, which is applied in the direction of ceramic molding machines and manufacturing tools, can solve problems such as insufficient cleaning, affecting mold sealing, and mold damage, so as to reduce friction, ensure safety and service life, The effect of ensuring airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

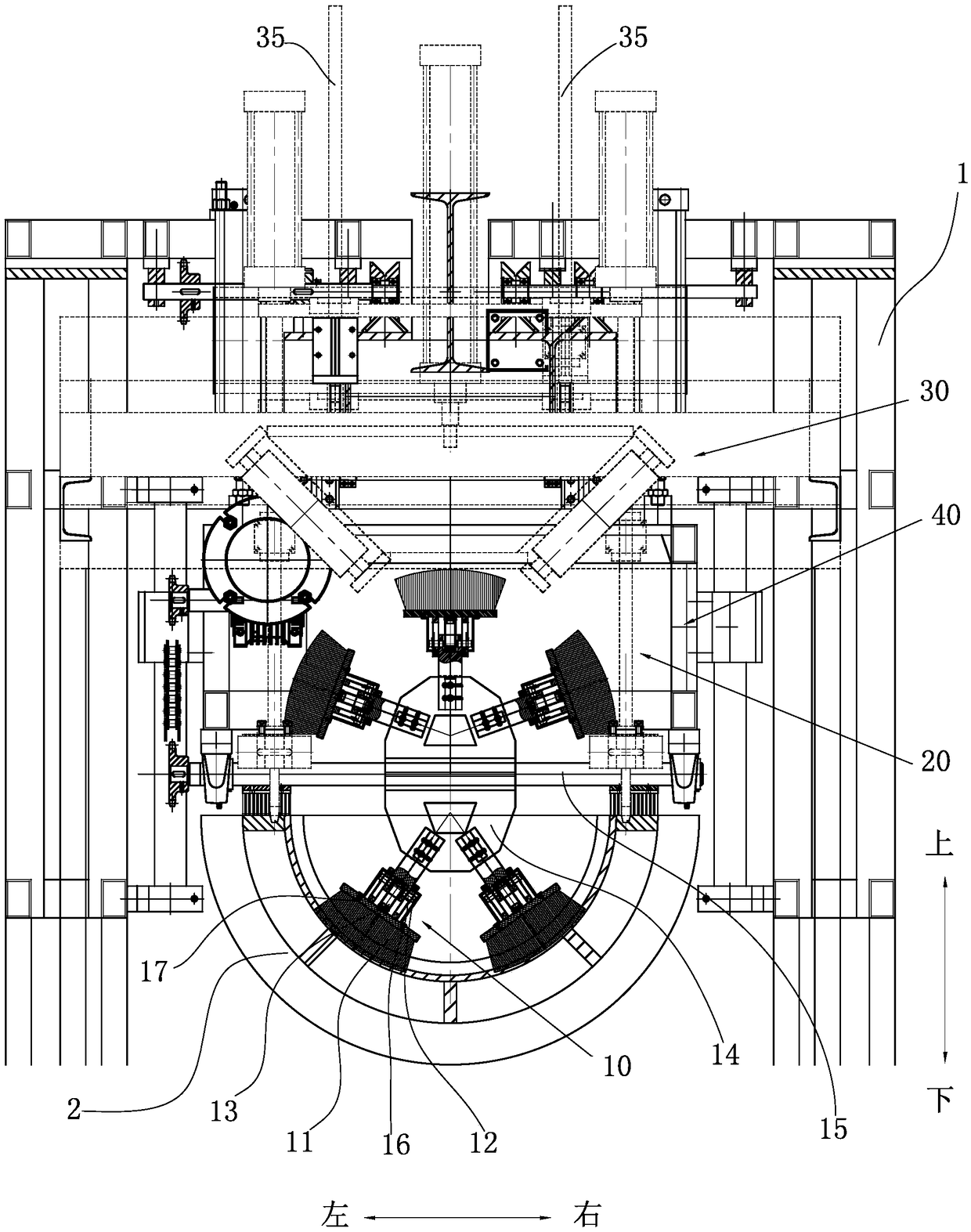

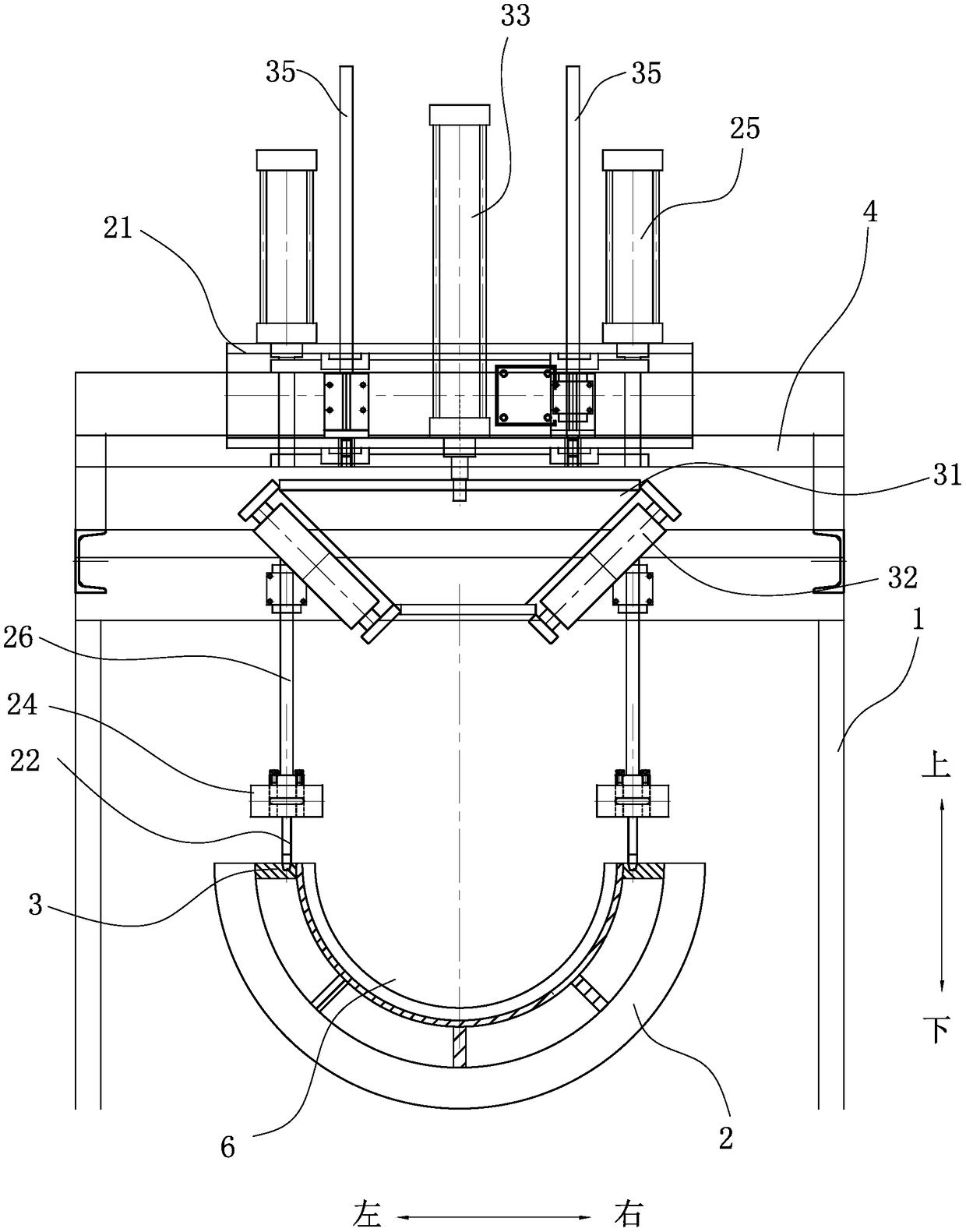

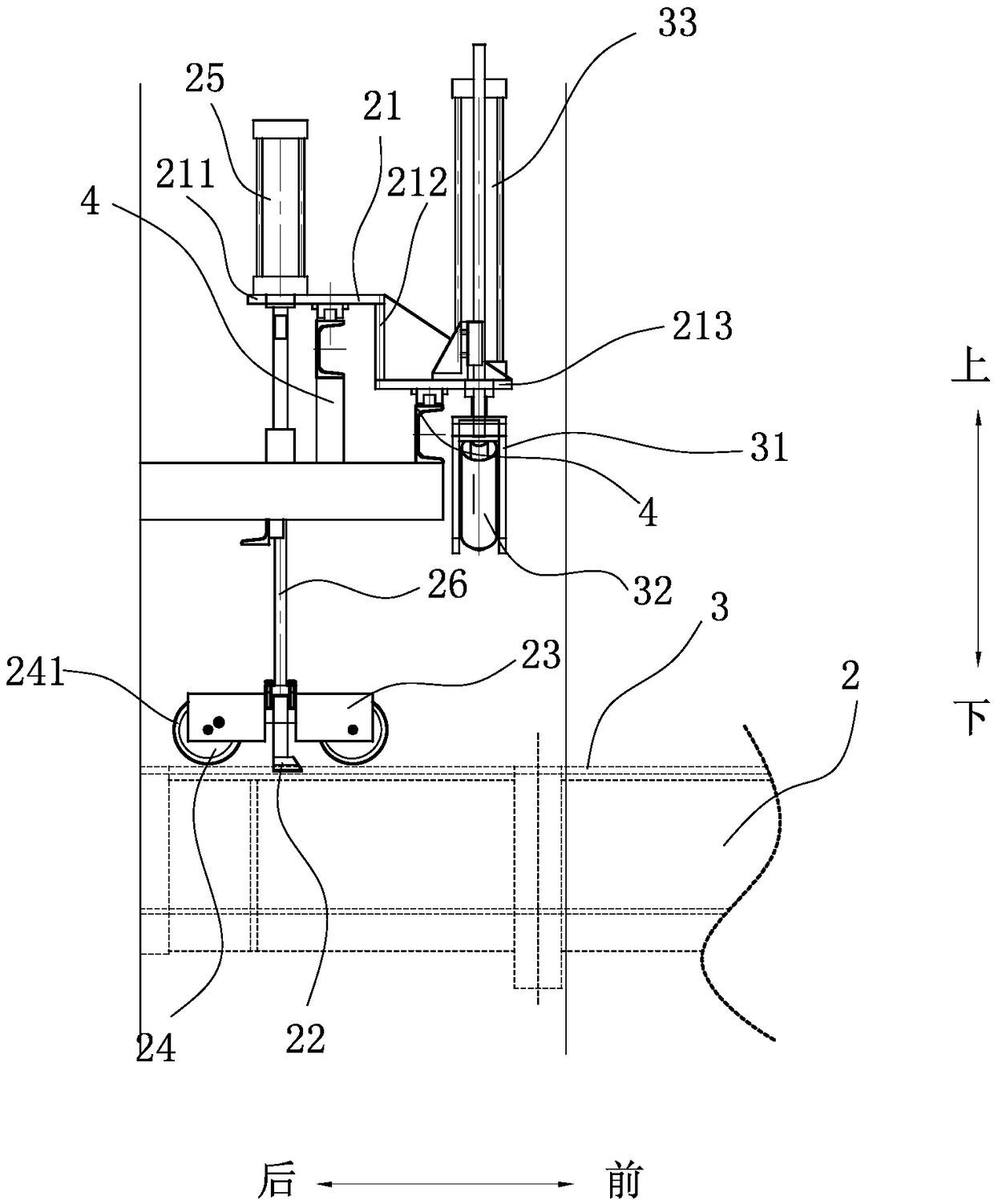

[0026] Such as Figure 1~5 As shown, a centering guide mechanism of a pipe mold cleaning machine, the pipe mold cleaning machine includes a frame 1, a brush frame 40 is installed in the frame, and the brush frame 40 is rotatably connected with a brush with a brush head 11 installed on the edge. The disk assembly 10 is equipped with a scraper device 20 and a centering guide mechanism 30 on the frame 1 . The scraper device 20 includes a scraper frame 21, a scraper 22 and a connecting rod 26 symmetrically arranged on the scraper frame 21, the transverse section of the scraper 22 is generally a right-angled trapezoid, and the front is a slope for scraping. The scraper frame 21 is arranged on the guide rail beam 4 on the upper end of the frame 1 , the guide rail beam 4 is arranged generally along the radial direction of the pipe mold, and the scra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com