Mechanical arm space trajectory optimization method for optimal time under multiple constraint conditions

An optimal time and trajectory optimization technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as not considering constraints, not being able to obtain the optimal solution of time, and easily falling into local extremum, etc., to achieve increased The effect of diversity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described below in conjunction with accompanying drawing.

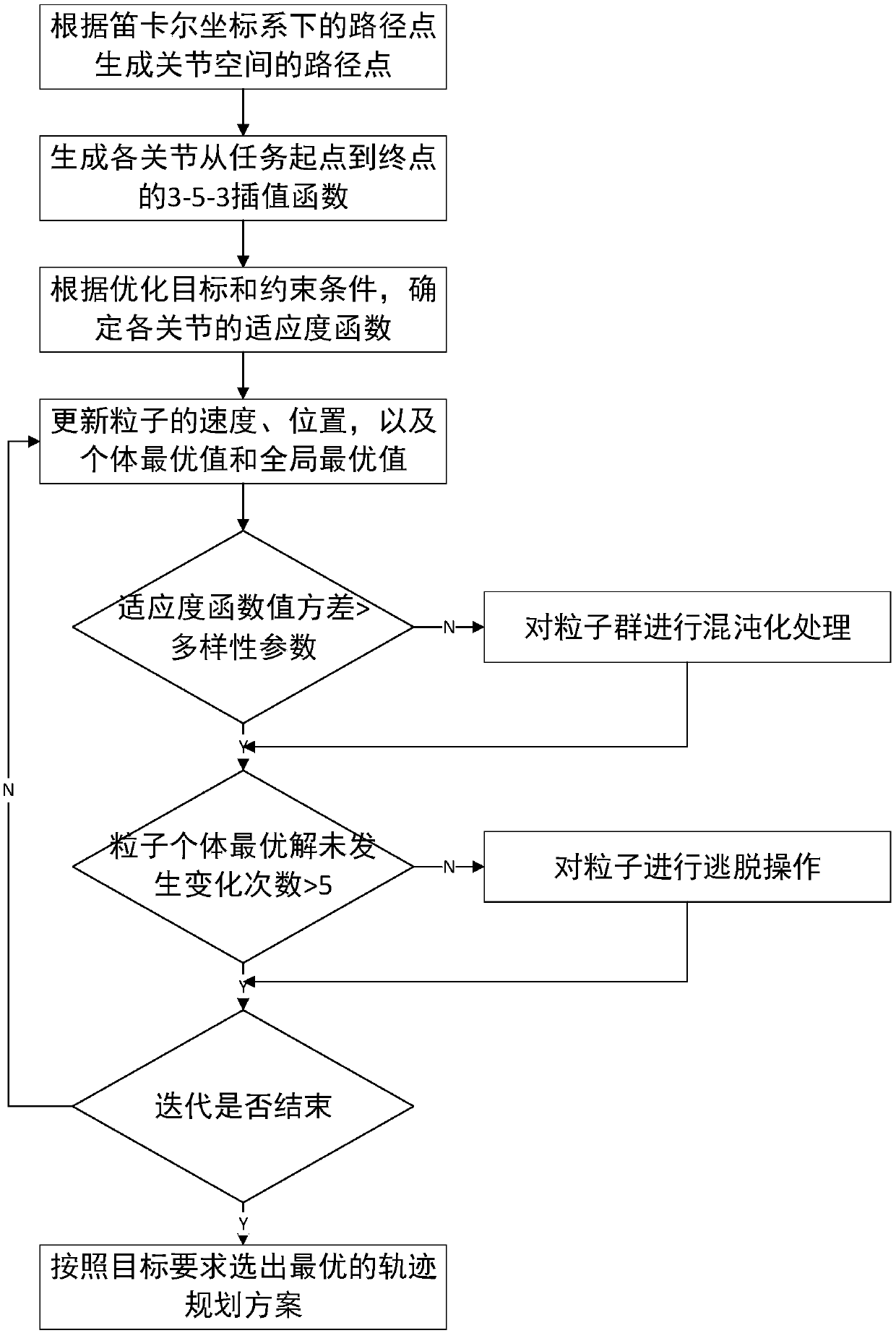

[0060] figure 1 It is a flow chart of the method of the present invention, combined with figure 1 Shown:

[0061] 1. Generate path points in joint space based on path points in the Cartesian coordinate system

[0062] Convert the trajectory in the Cartesian coordinate system of the end effector of the manipulator to the angle change in the joint coordinate system, and set the path point θ that the manipulator needs to pass through to complete the entire trajectory:

[0063] θ={θ sr |s=1,...m; r=1,...n+1}

[0064] Among them, θ sr Indicates the position of the rth waypoint of the sth joint, m is the number of joints of the robot arm, and n+1 is the number of waypoints.

[0065] 2. Generate a 3-5-3 interpolation function for each joint from the start point to the end point of the task

[0066] Assuming that a joint of the manipulator moves from two points B and C on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com