Calibration method for numerical control machining-based coordinate system

A calibration method and the technology of the base coordinate system, which are applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of time-consuming, labor-intensive, heavy workload of technicians, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

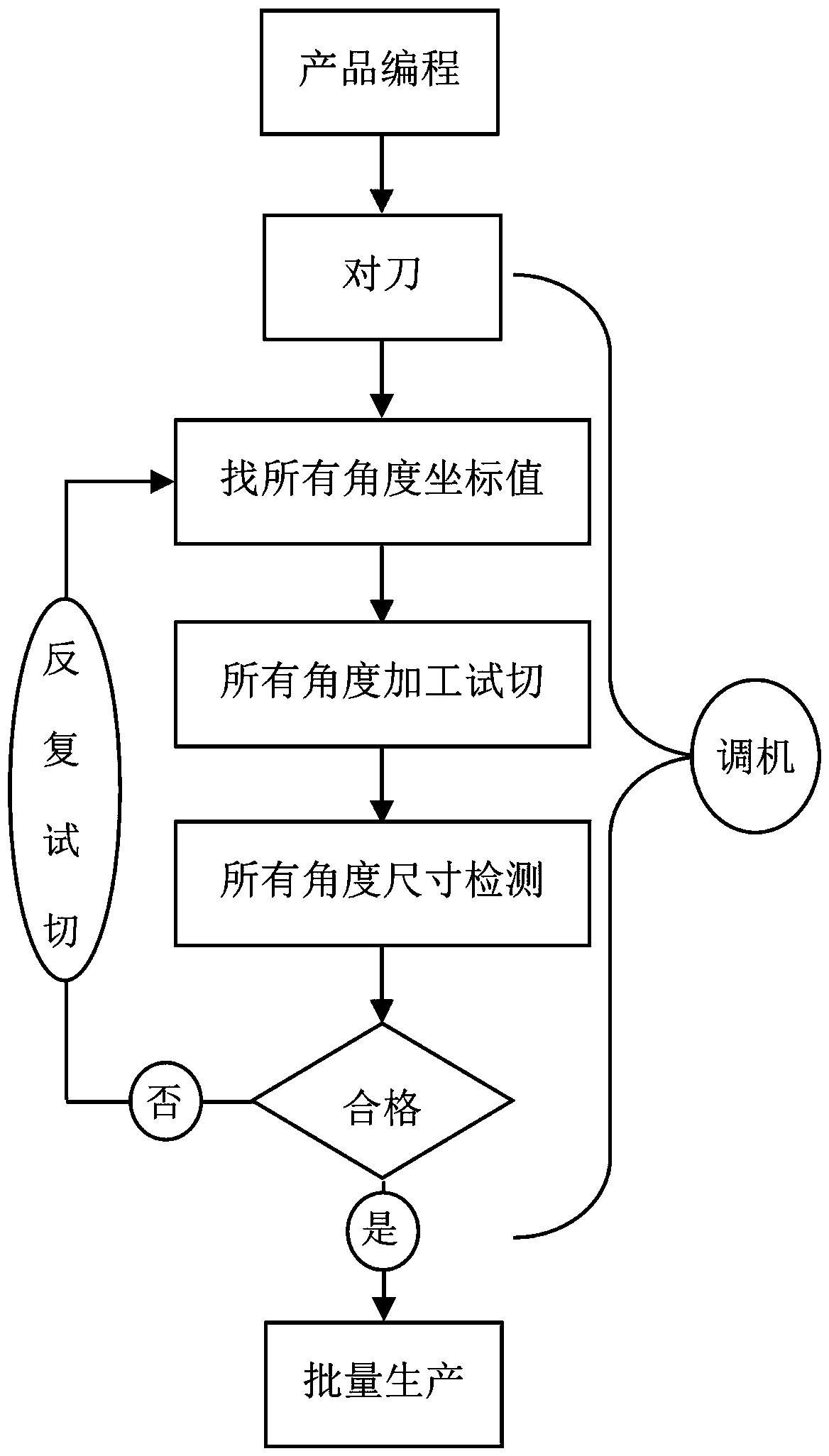

Problems solved by technology

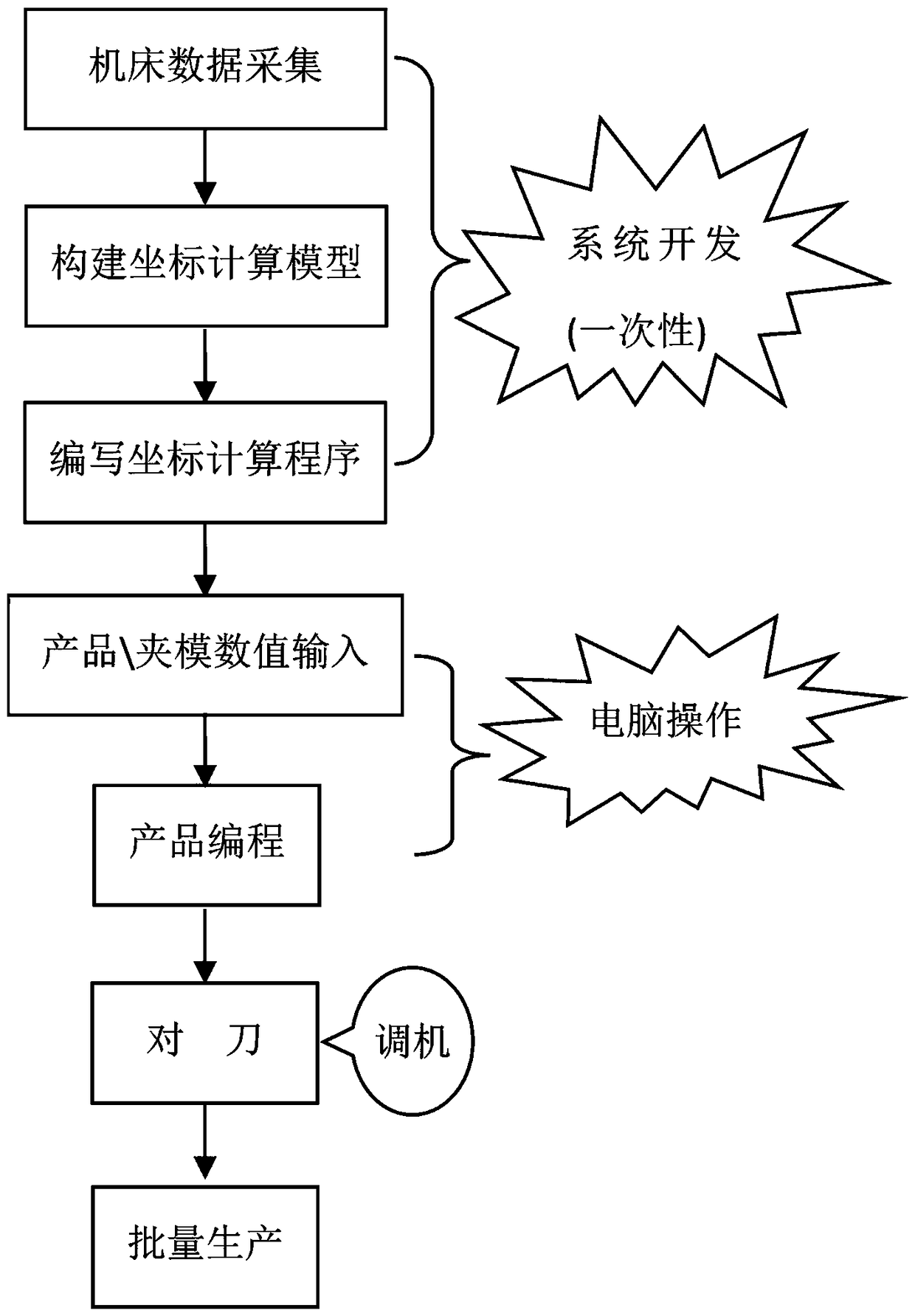

Method used

Image

Examples

Embodiment Construction

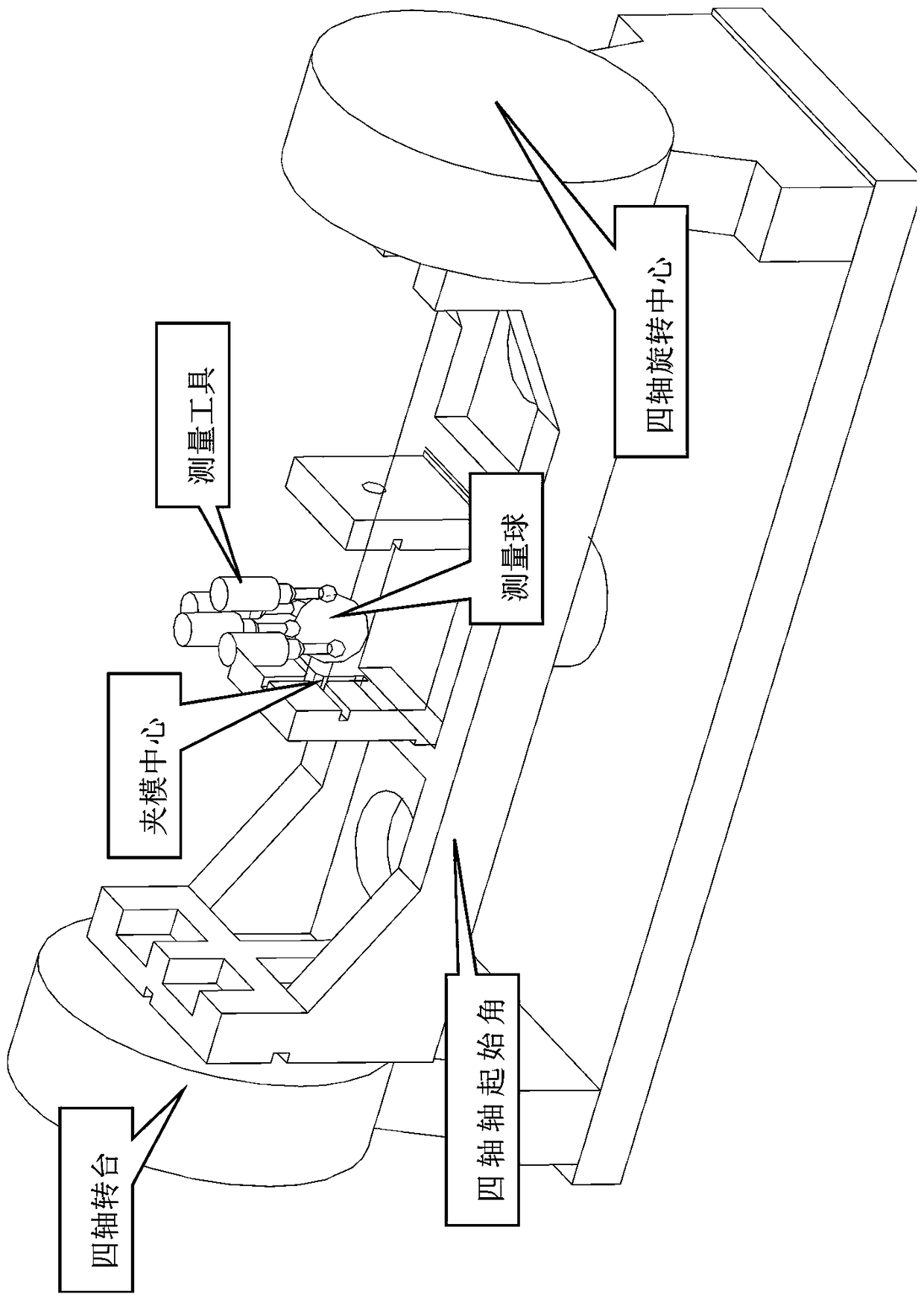

[0051] combine Figure 2 to Figure 7 Take a vertical CNC machine tool equipped with a four-axis turntable as an example to describe the specific implementation.

[0052] The present invention relates to a method for calibrating a numerically controlled machining base coordinate system. The numerically controlled machine tool is equipped with a four-axis turntable, which specifically includes the following steps:

[0053] Step 1. Collect machine tool data

[0054] (1) Calibrate the horizontal position of the clamping die mounting frame with a dial indicator, perform zero point correction on the A-axis starting angle of the four-axis turntable, and collect the A0 starting angle value of the A-axis of the four-axis turntable;

[0055] (2) Measure the center point of the four-axis rotation and calculate the center track of the clamping mold installation

[0056] Such as Figure 3A As shown, the measuring tool is installed on the spindle of the CNC machine tool, and the measuring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com