Bottle cap assembly equipment

A technology for assembling equipment and bottle caps, which is applied in the direction of metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of low production volume, time-consuming and laborious, etc., and achieve the effect of solving work output and high labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

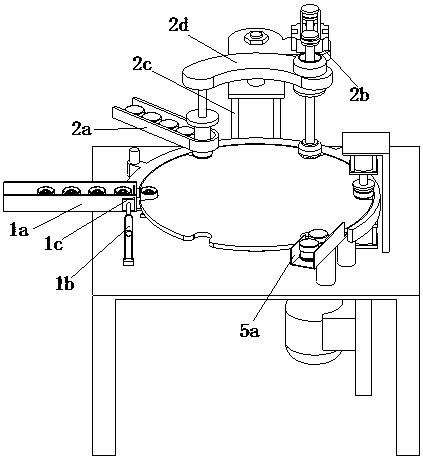

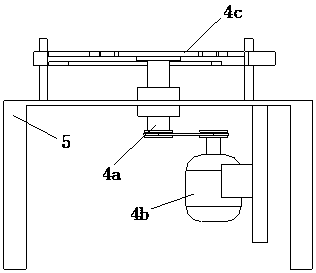

[0029] refer to Figure 1 to Figure 8 The shown bottle cap assembly equipment includes a base 5, and also includes an inner cap feeding assembly 1, an outer cap mounting assembly 2, a pressing assembly 3, a discharge chute 5a and a rotating assembly 4, the rotating assembly 4 Fixedly installed on the base 5, the rotating assembly 4 includes a rotating shaft 4a, a rotating motor 4b and a turntable 4c, the rotating motor 4b is arranged at the bottom of the base 5, and one end of the rotating shaft 4a passes through the base 5 and is connected with the rotating motor 4b by a belt , the turntable 4c is horizontally arranged at the other end of the rotating shaft 4a, and several station slots 4d are also arranged on the turntable 4c, the inner cover feeding assembly 1, the outer cover installation assembly 2, the pressin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com