Equipment for manufacturing ring type components

A technology of ring parts and equipment, which is applied in the field of equipment for producing large quantities of small-sized ring parts, can solve the problems of waste of materials and energy, prolong the manufacturing cycle, increase manufacturing costs, etc., and achieve simplified forging process, improved processing efficiency, The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

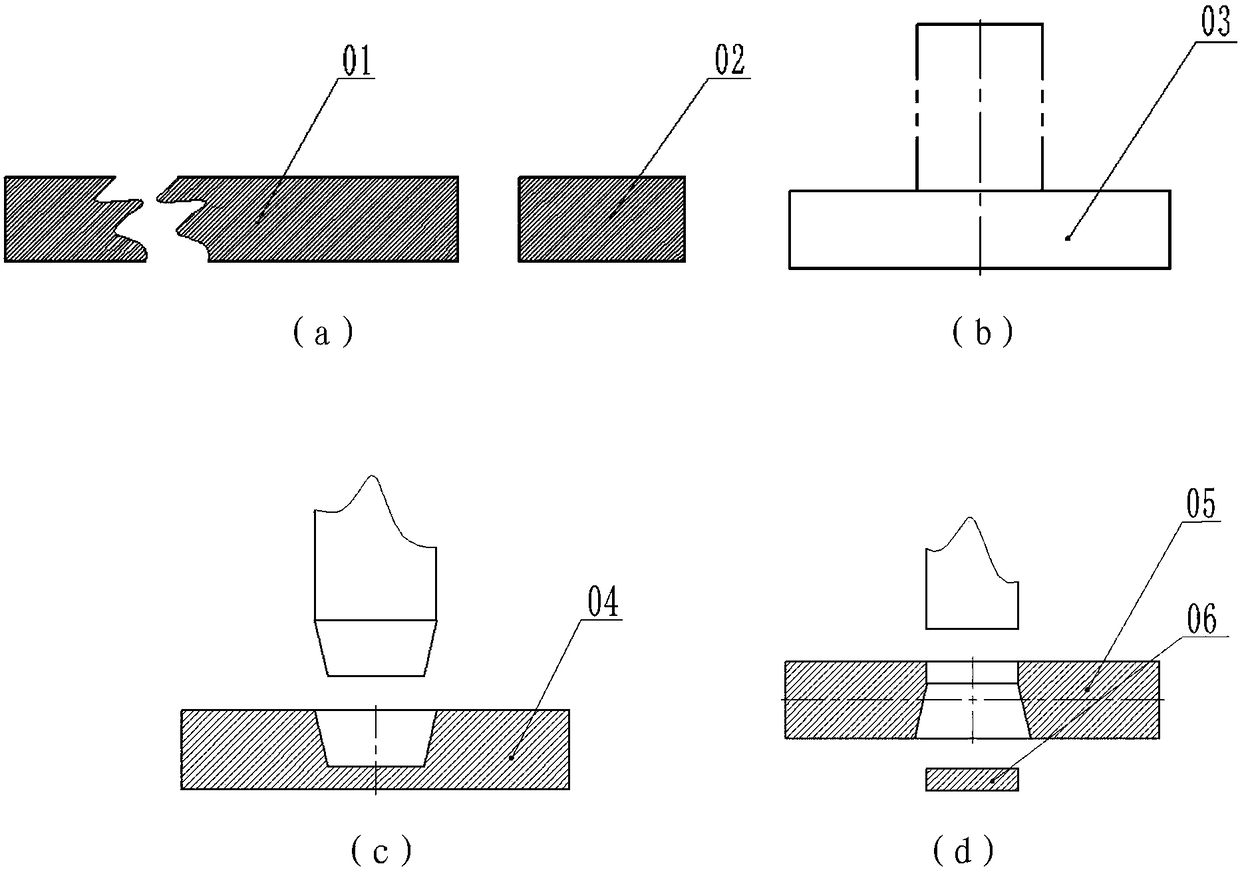

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

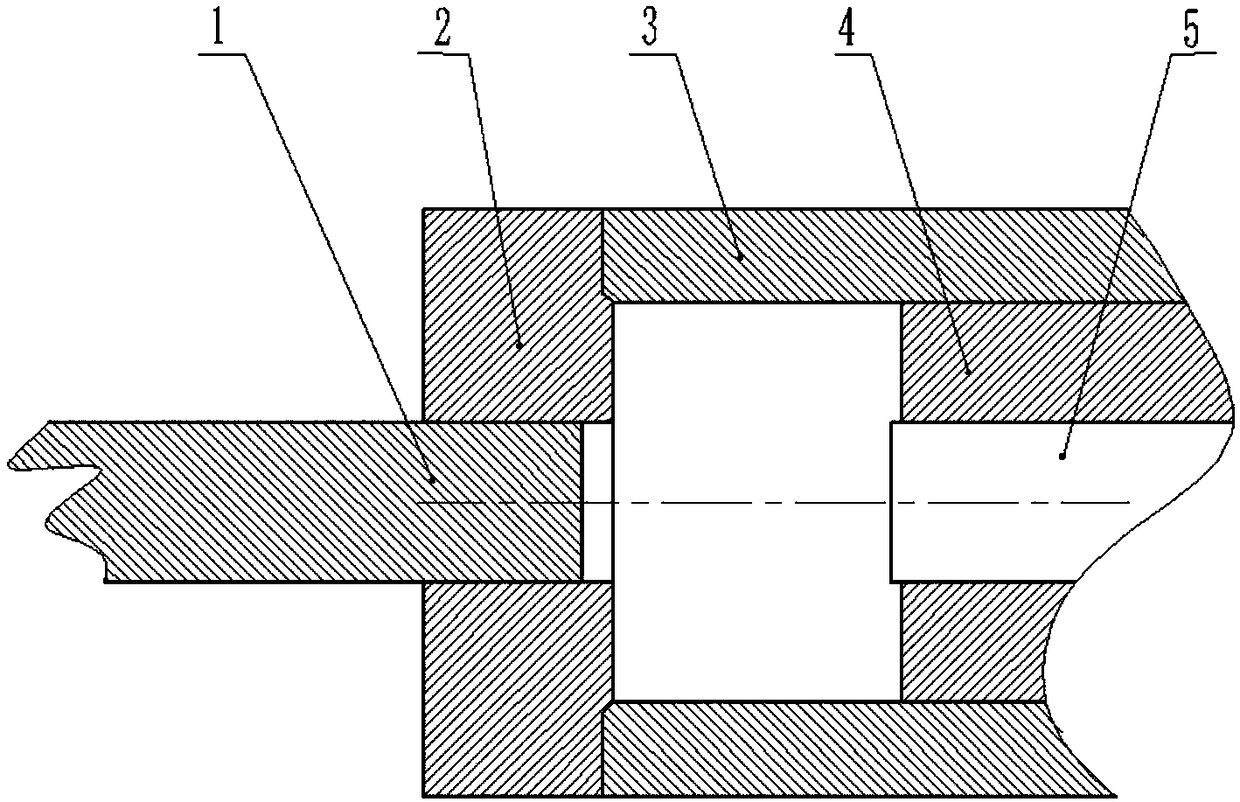

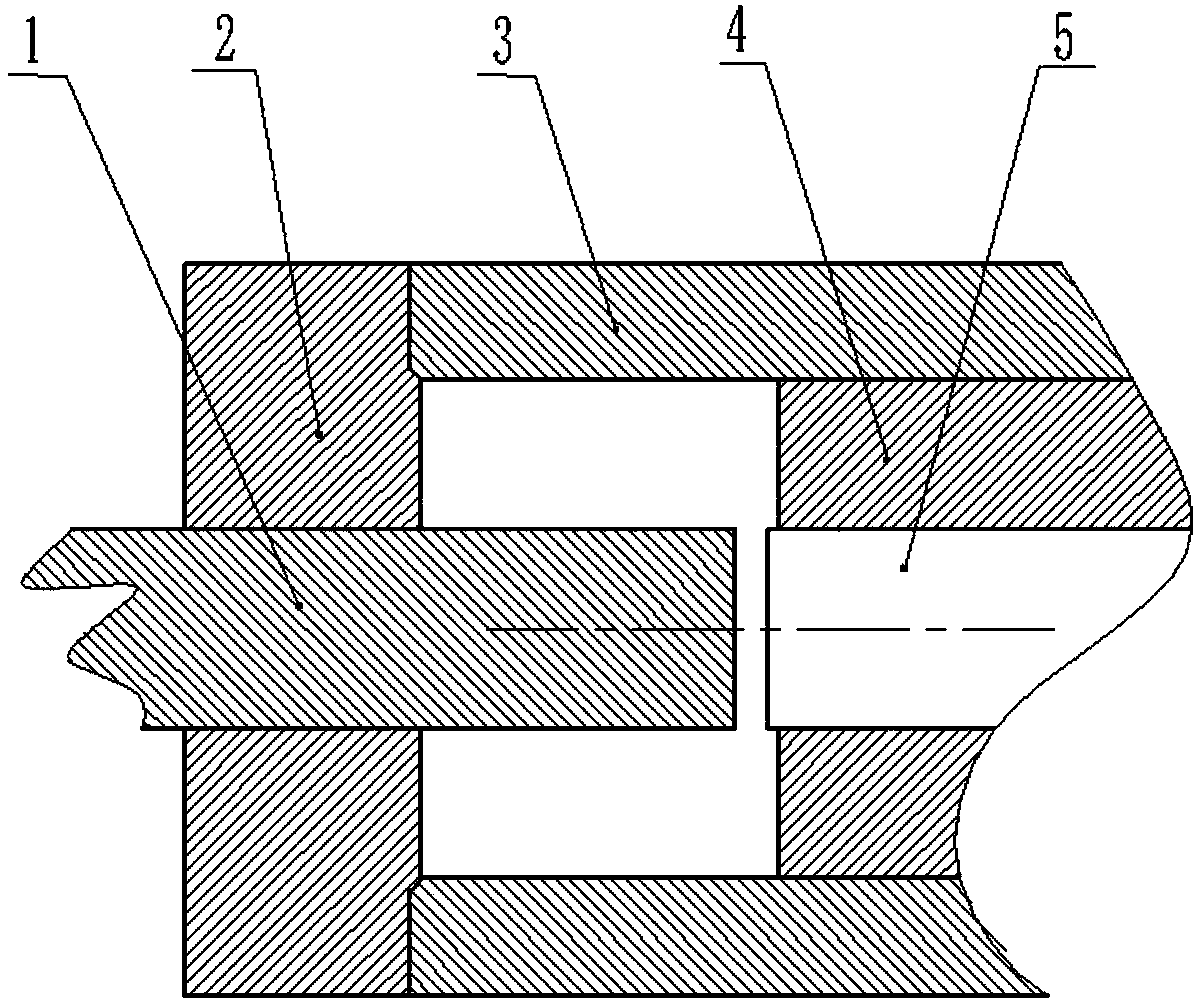

[0024] The present invention will be further described below in conjunction with accompanying drawing:

[0025] The processing object of this embodiment is the rod-shaped raw material 1 .

[0026] In order to process the rod-shaped raw material 1 into a ring shaped workpiece 6, the equipment provided in this embodiment is as figure 2 As shown, it includes a die 2 and a movable die 3 matching with the die 2 to form a closed cavity. The die 2 is composed of two parts that can move along its radial direction. The space for clamping the raw material 1 is formed after each part is docked, and each part is respectively connected with a heating mechanism. The heating mechanism here is an electric heating rod. The die 2 can be fixed on the workbench, and the movable die 3 can be driven by the first driving mechanism to move axially along the die 2 . The end face of the die 2 is radially designed with a limit step that matches the movable die 3, and the part of the limit step that i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com