Forging device and forging method for multi-directional die forging of large complex forgings

A complex forging, multi-directional die forging technology, applied in forging/pressing/hammer devices, manufacturing tools, forging/pressing/hammering machinery, etc. High efficiency, good quality and the effect of simplifying the forging process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

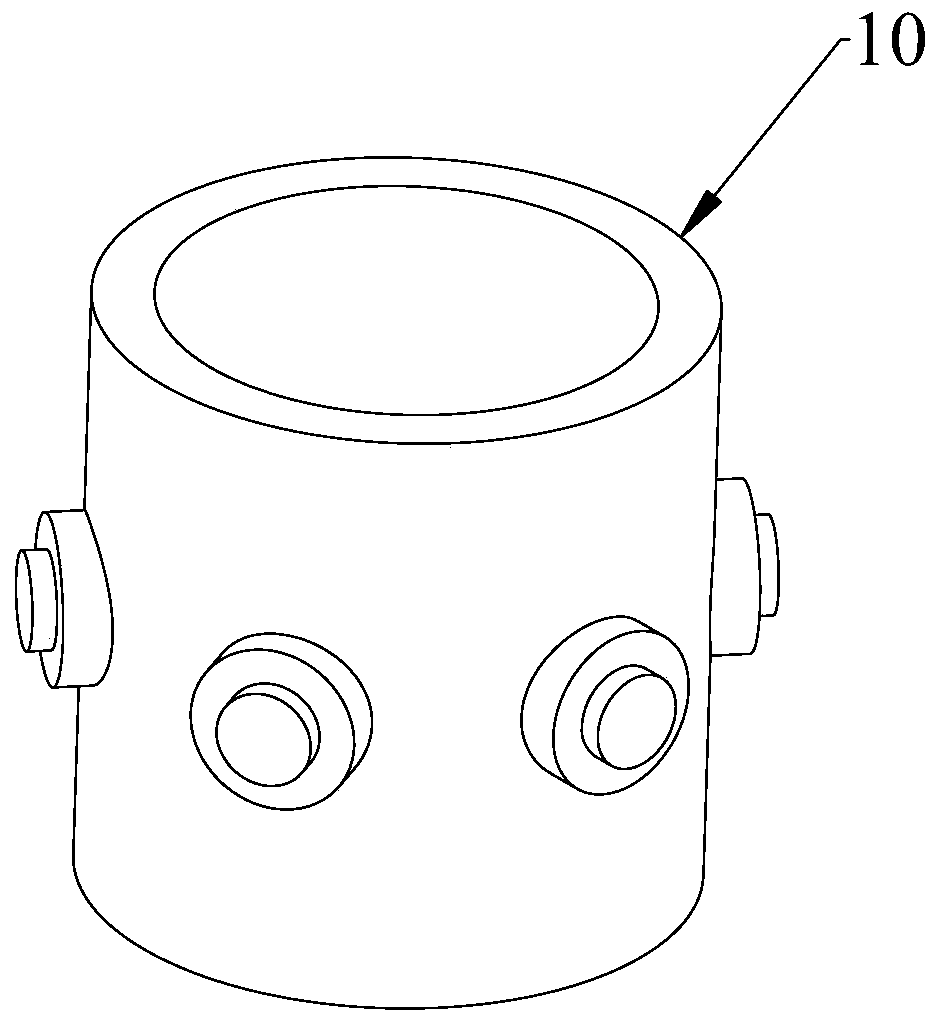

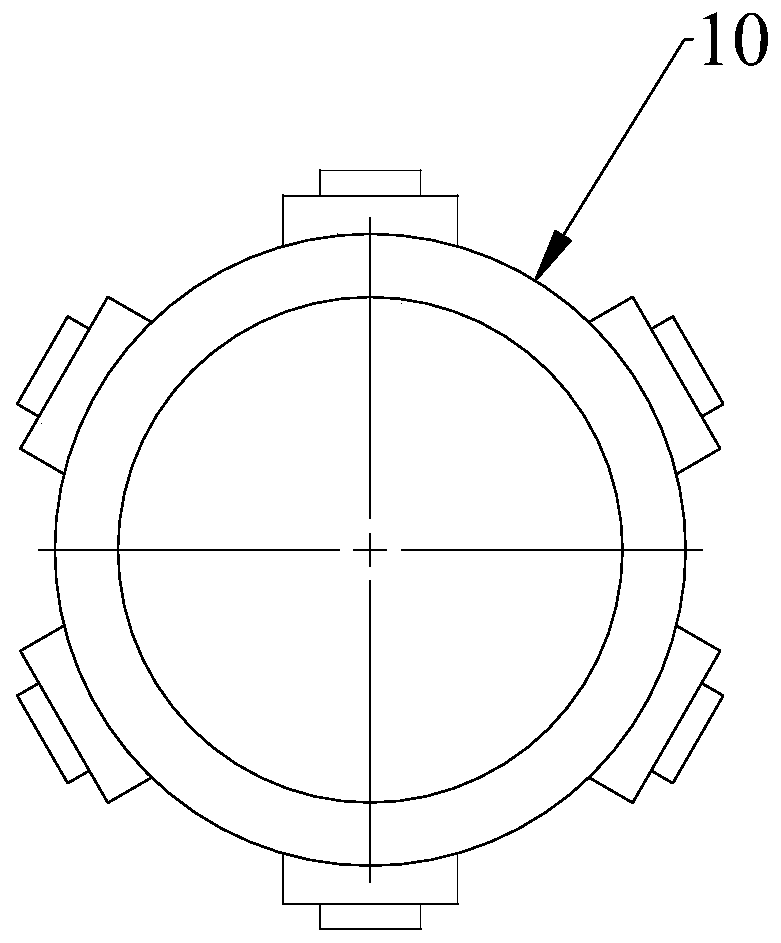

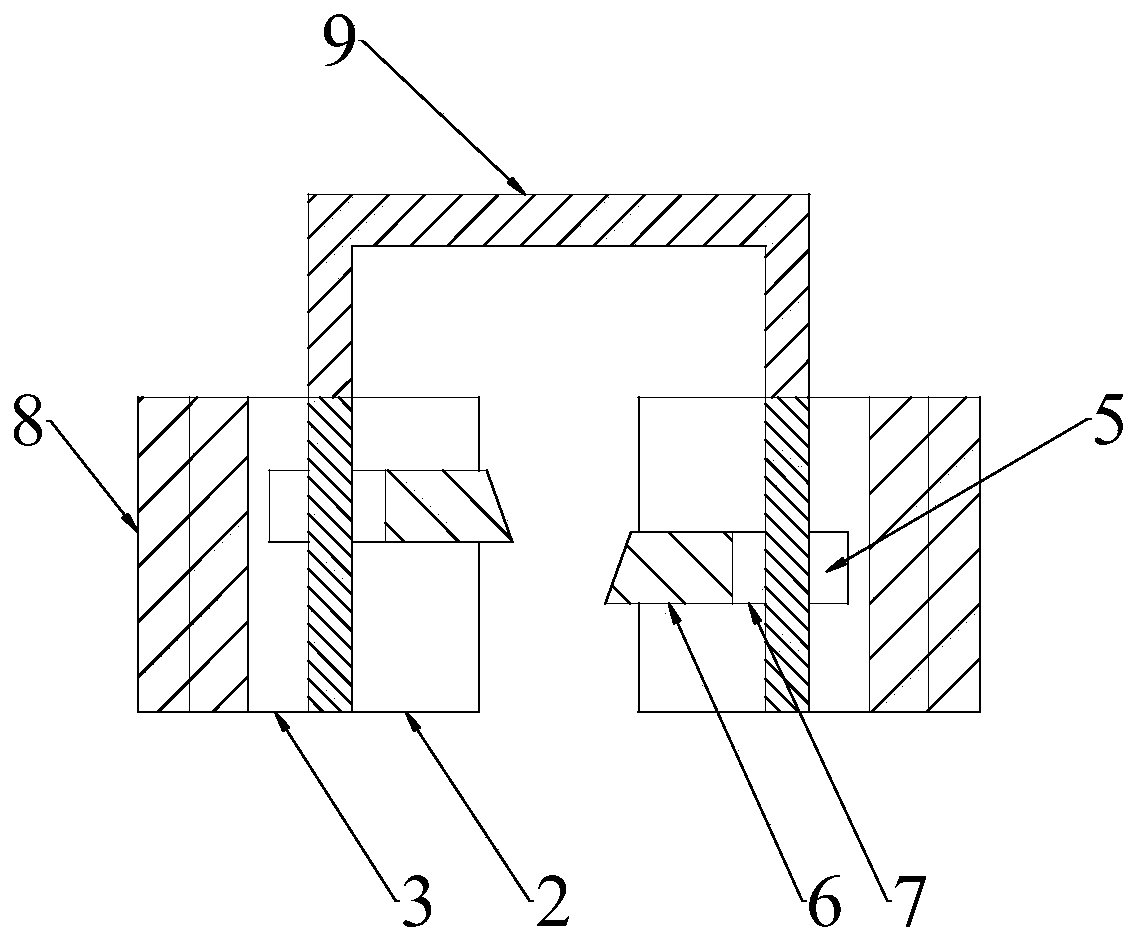

[0034] see in conjunction Figure 3 to Figure 8 , the present invention provides a multi-directional die forging forging device for large complex forgings, including a first upper die 9, a second upper die 1, a first lower die 2 and a second lower die 3; the first lower die 2 A through hole 4 is opened on the side wall of the through hole 4, and a molding pin is arranged in the through hole 4; the second lower mold 3 is detachably sleeved on the outer periphery of the first lower mold 2, and the inner surface of the second lower mold 3 is provided with a through hole 4. The die chamber 5 corresponding to the hole 4; the first upper mold 9 squeezes the blank into between the first lower mold 2 and the second lower mold 3 for arranging the blank, and the second upper mold 1 cooperates with the forming pin to push the blank A boss structure is formed in the die cavity 5 .

[0035] The forging device used for multi-directional die forging of large and complex forgings provided by...

Embodiment 2

[0052] According to another aspect of the present invention, an embodiment of the present invention also provides a forging method based on the forging device for multi-directional die forging of large complex forgings in Embodiment 1, including:

[0053] S1. Upsetting and punching the blank to form a preform;

[0054] In this step, materials such as steel ingots can be selected as the blank, and the steel ingot is upset and punched first, so as to obtain the cylinder blank;

[0055] S2. Squeeze the preform into between the first lower mold 2 and the second lower mold 3 through the first upper mold 9, so that the blank fills the gap between the first lower mold 2 and the second lower mold 3;

[0056] In this step, the preform formed in step S1 is squeezed between the first lower die 2 and the second lower die 3 through the extrusion of the first upper die 9, that is, the first upper die 9 The blank is pre-forged so that the blank fills the gap between the first lower die 2 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com