Efficient cyclone dust removal device and dust removal method thereof

A cyclone dust removal and high-efficiency technology, which is applied in the direction of combined devices, separation methods, chemical instruments and methods, etc., can solve the problems of low dust removal efficiency and inability to remove small-size dust in the airflow, and achieve high dust removal efficiency, improve dust removal efficiency, and remove dust. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

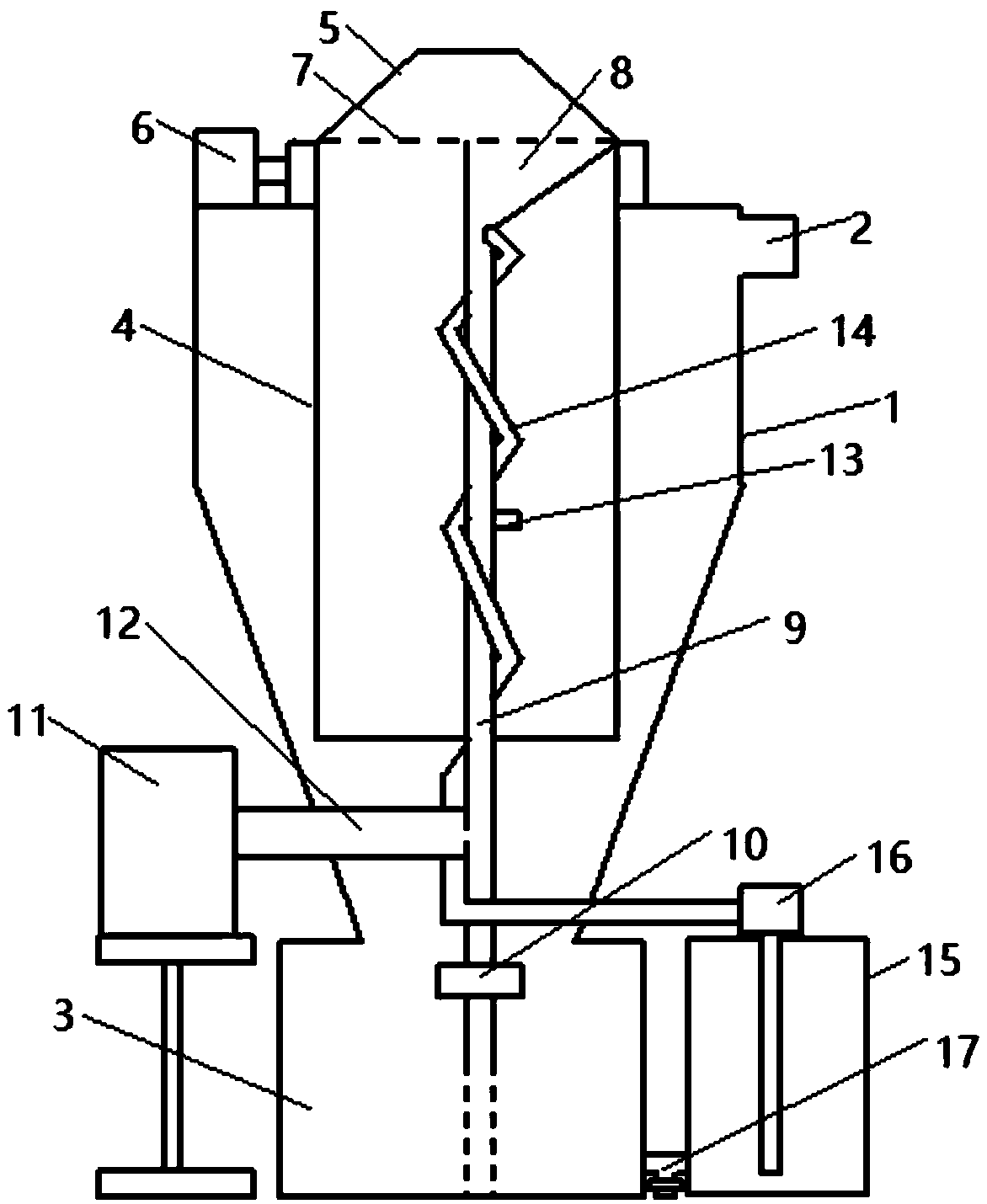

[0030] Such as figure 1 As shown, the present invention provides a kind of efficient cyclone dedusting device, comprising:

[0031] The outer shell 1 includes an integrally formed cylindrical upper shell and a truncated conical lower shell. The upper part of the outer shell 1 is provided with a waste gas inlet 2 along its tangential direction. The bottom of the outer shell 1 is connected to a storage tank. Ash tube 3 is detachably connected;

[0032] The inner casing 4 is sheathed inside the outer casing 1 and arranged coaxially therewith. A cavity for waste gas to pass is formed between the inner casing 4 and the outer casing 1. The inner casing 4 The upper part protrudes from the outer shell 1 and is tightly and rotationally connected with it, and the upper edge of the inner shell 4 shrinks upwards and inwards to form the mouth 5 of the truncated cone. The inner shell 4 is driven by a bidirectional motor 6 through a drive driving rotation, the driving member includes but i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com