Edible fungi cultivation formula and simple type tunnel cultivation method thereof

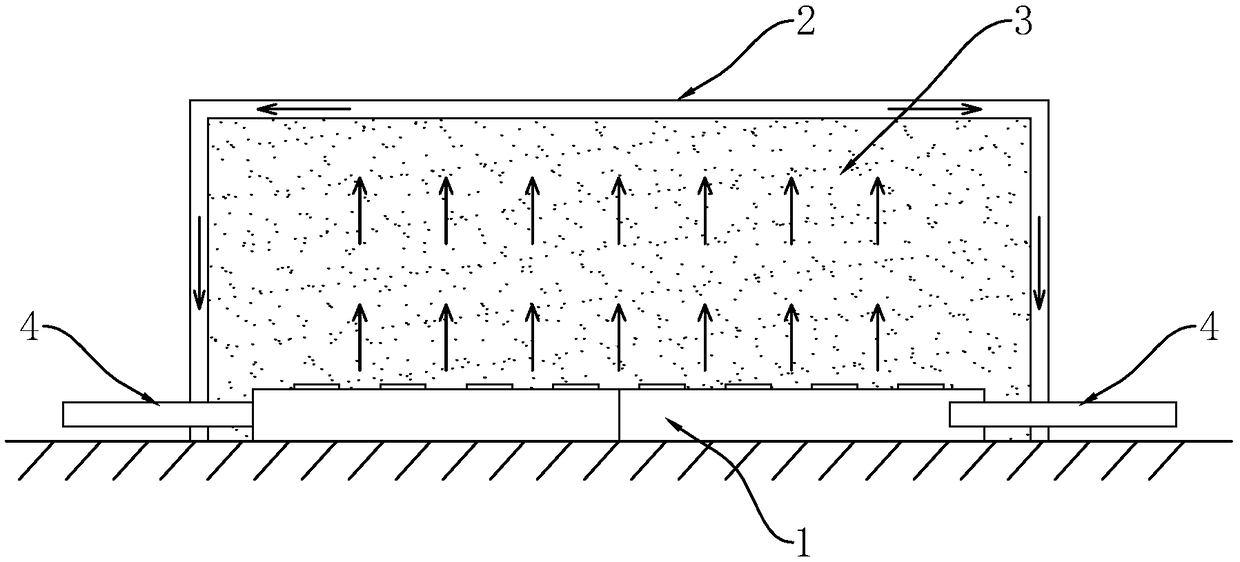

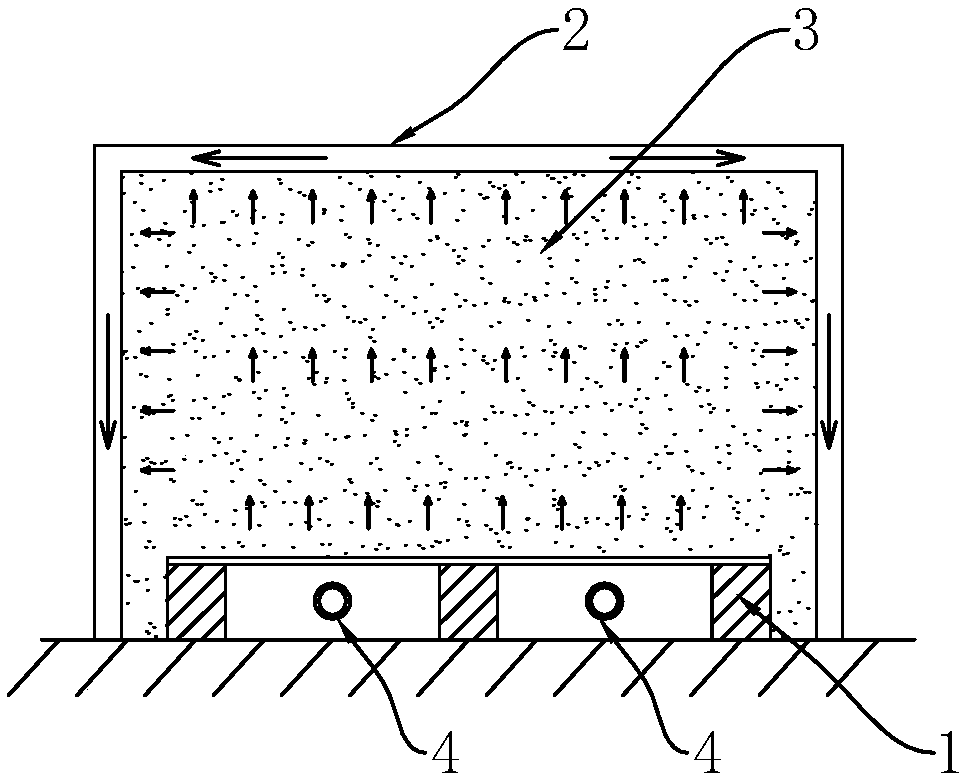

A cultivation method and technology of edible fungi, which are applied in cultivation, plant cultivation, mushroom cultivation, etc., can solve the problems that the overall quality of fermented materials cannot be improved, rancidity occurs in the fermentation process, and the investment cost is high, so as to reduce ammonia production and kill Bacteria and insect damage, the effect of uniform air flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

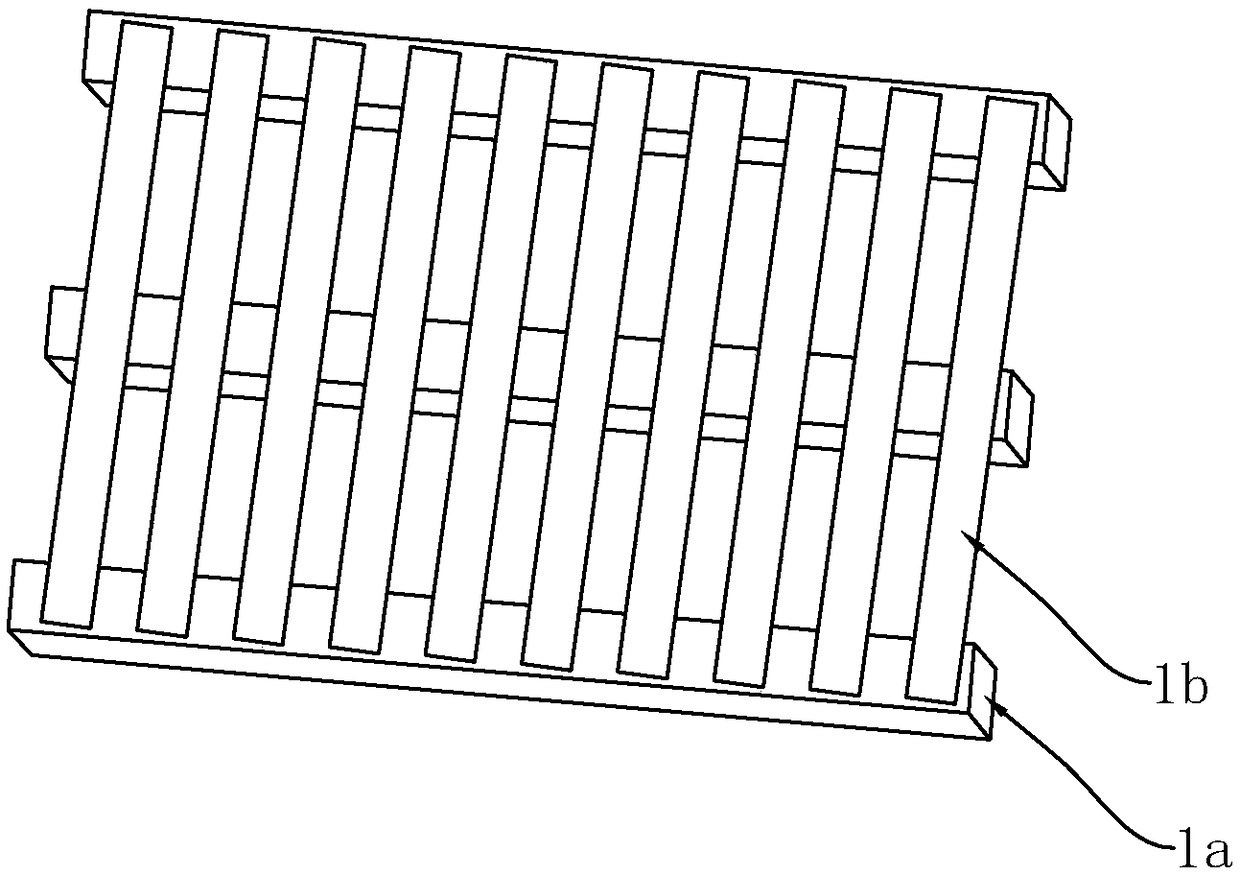

Method used

Image

Examples

Embodiment 1-1

[0038] Example 1-1: A cultivation formula for edible fungi, which consists of 63 kg of corncobs, 20 kg of sawdust, 10 kg of wheat bran, 5 kg of lime powder, 1.0 kg of gypsum powder, and 1.0 kg of superphosphate;

Embodiment 1-2

[0039] Example 1-2: A cultivation formula for edible fungi, consisting of 60 kg of corncobs, 18 kg of sawdust, 8 kg of wheat bran, 4 kg of lime powder, 0.8 kg of gypsum powder, and 0.8 kg of superphosphate;

Embodiment 1-3

[0040] Example 1-3: A cultivation formula for edible fungi, consisting of 65 kg of corncobs, 22 kg of sawdust, 12 kg of wheat bran, 6 kg of lime powder, 1.2 kg of gypsum powder, and 1.2 kg of superphosphate;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com