A kind of field calibration and fixed focus method of ptz camera

An on-site calibration and camera technology, applied in image analysis, image enhancement, image data processing, etc., can solve the problems of PTZ camera parameter calibration and uneven processing accuracy, and achieve the effect of reducing the calibration workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0023] In the existing PTZ camera self-calibration method, a polynomial distortion model is used to fit the lens distortion, but for a lens that is not strictly axisymmetric, a simple distortion model cannot be used to fit it. In order to solve this problem, the present invention proposes a PTZ camera on-site calibration and focusing method, which can automatically calculate the internal parameter matrix of the distorted image and the distortion correction parameters of each pixel point, so as to achieve high-precision and automatic correction of lens distortion.

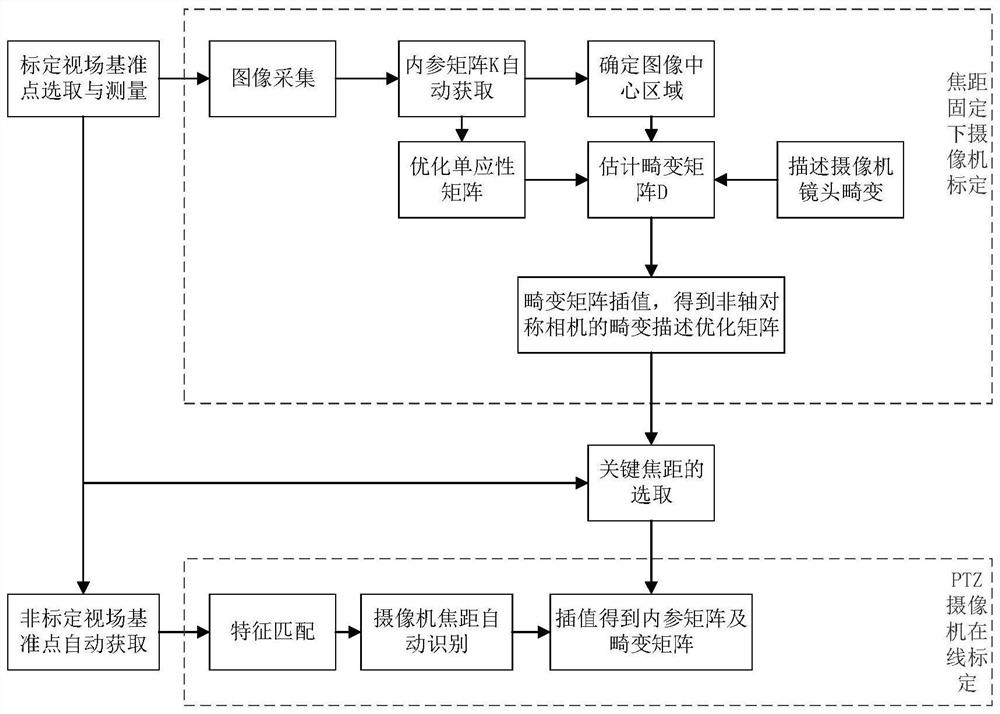

[0024] A PTZ camera on-site calibration and focusing method, the process is as follows figure 1 shown, including the following steps:

[0025] Step 1: Select and measure the reference point of the calibrated field of view;

[0026] The present invention uses the known reference po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com