Visual measurement system dynamic correction method based on zero-expansion ceramic calibration plate

A technology of visual measurement and system dynamics, applied in the field of correction, to reduce the impact and achieve the effect of distortion correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

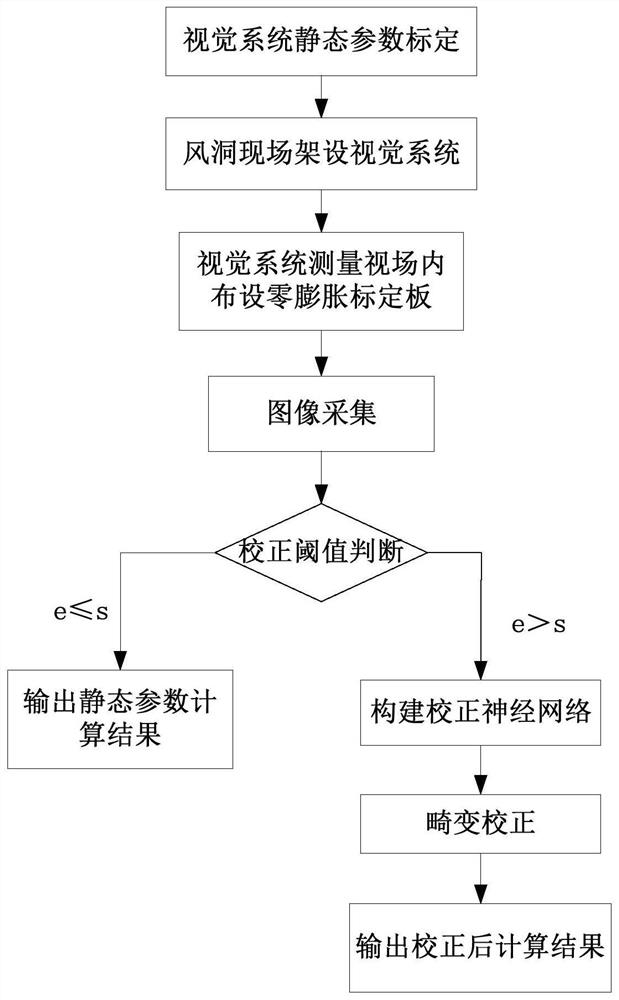

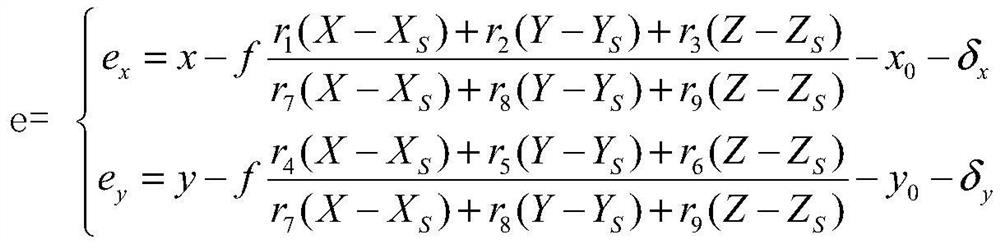

[0028] This embodiment provides a dynamic correction method for the visual measurement system based on the zero-expansion ceramic calibration plate, which is applied to the parameter optimization of the visual measurement system in the special environment of the wind tunnel test. In order to reduce the influence of the parameterized model on the measurement results, all Taking the distortion into account, and using the nonlinear learning ability of the neural network, it is a distortion correction method that does not depend on the internal parameters of the camera.

[0029] The visual measurement system is installed outside the observation window of the wind tunnel to measure the measured object in the wind tunnel through the observation window. The visual measurement system includes: two cameras, lenses, image acquisition computer and cables;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com