Testing method, device, system and storage medium for electronic equipment

A technology of electronic equipment and testing methods, applied in the field of communication, can solve the problems of low production line testing efficiency, and achieve the effect of shortening production line testing time and shortening production line testing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

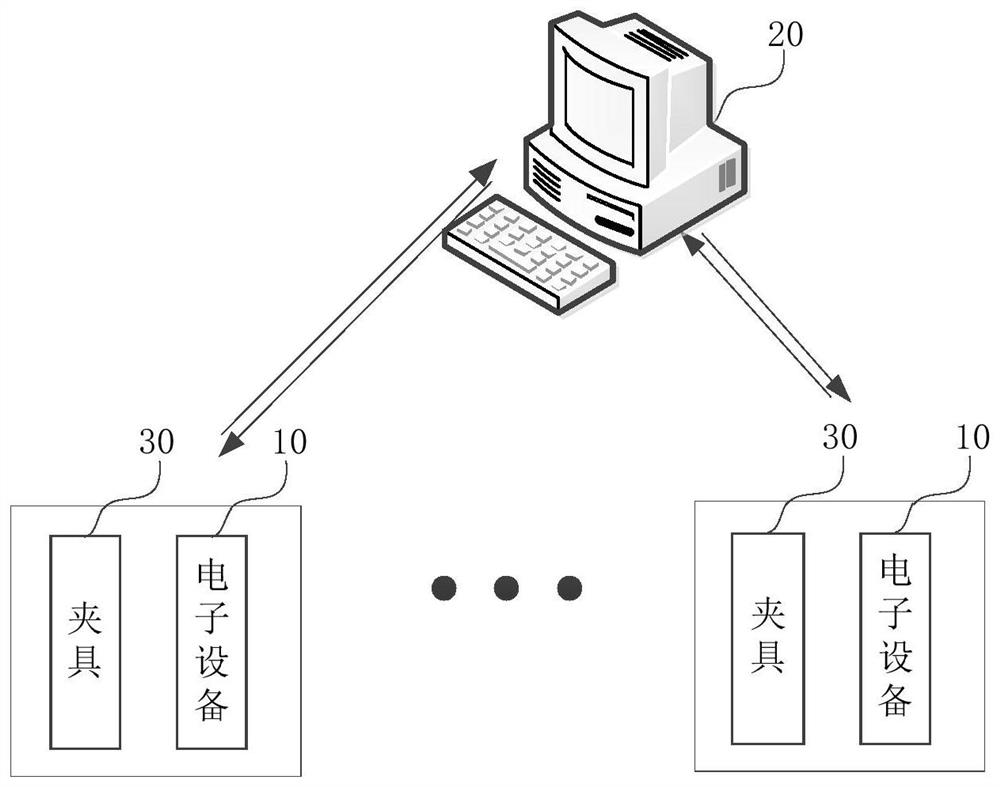

[0050] The testing method for an electronic device provided by the embodiment of the present invention can be applied to figure 1 The test system of the electronic device shown, the test system of the electronic device includes: a plurality of electronic devices 10, a host computer 20 and a fixture 30 for holding the electronic device 10, each electronic device 10 is respectively connected with the host computer 10. machine 20 is connected. Optionally, the above-mentioned electronic device 10 may be a mobile phone terminal, a tablet computer, or a smart terminal such as a smart bracelet, a smart watch, or the like. Optionally, the above-mentioned upper computer 20 may be a computer device with a data processing function, such as a PC stand-alone computer or a server. The above-mentioned clamp 30 can be used to clamp the electronic device 10, and can be provided with a slot for placing the electronic device 10, a positioning hole for calibrating the position of the electronic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com