Antiskid membrane resin lens and production process thereof

A resin lens and production process technology, applied in the field of lenses, can solve the problems of inconvenient batch operation, affecting production efficiency, trouble attaching and removing anti-skid stickers, etc., achieving scientific film system and production process design, obvious anti-skid effect, and convenience. Effects of bulk operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

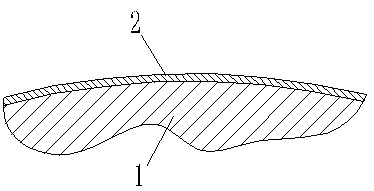

[0022] In this embodiment, preferably 1.598 acrylic (acrylic resin) materials are coated with 250 super waterproof film lenses, and a layer of fluoride is coated by vacuum coating, and the fluoride is magnesium fluoride, calcium fluoride, potassium fluoride, fluorine Any one or more of aluminum chlorides, with a thickness of 40 nm to 60 nm, to obtain anti-slip film resin lenses.

[0023] The anti-slip film resin lens of the present invention comprises a super waterproof film lens 1 and an anti-slip film, and the super waterproof film lens 1 is a resin lens coated with a super waterproof film on the outer surface, and the lens includes a plano lens, a myopia lens, and a hyperopia lens Or presbyopia lens, described anti-slip film comprises outer anti-slip film 2 and inner anti-slip film 3, and described anti-slip film is fluoride film, and thickness is preferably 40nm, and in this embodiment, described fluoride is preferably fluorine magnesium oxide.

[0024] The production pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com