A bms AC charging process simulation test equipment

A technology of AC charging and process simulation, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of high cost, long time consumption, and a large amount of test time spent waiting for the battery to be fully charged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

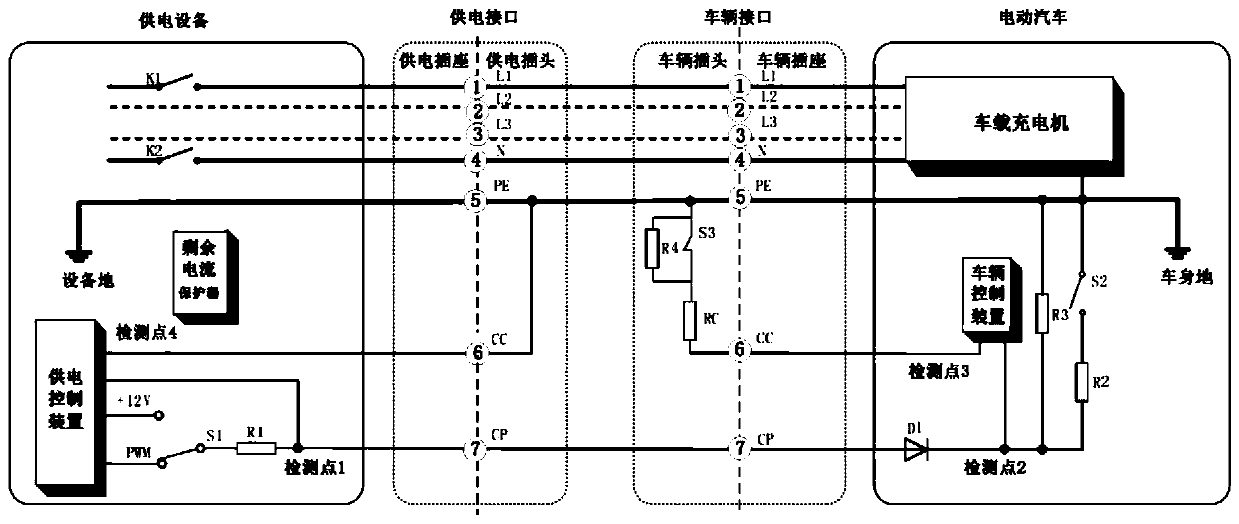

[0088] Figure 4 It is the simulation test equipment for the BMS AC charging process of this embodiment (hereinafter referred to as the equipment of this embodiment, that is, Figure 4 The analog device in ), when the interface is docked with the BMS connector, the schematic diagram of the circuit connection relationship with the BMS. In this embodiment, a PC is used as a display module, and the device in this embodiment is connected to the PC through its UART terminal. After docking the device interface of this embodiment with the BMS connector, it is realized Figure 4 The docking relationship between the simulated device and the BMS. Figure 4 The PWR_CTRL, CAN, CC, and CP of the simulated device in the interface represent the pins connected to the BMS power supply circuit, CAN signal transceiver circuit, CC signal circuit, and CP signal circuit in the interface, and the POWER, CAN, CC, and CP of the BMS represent the BMS respectively. Power input pins, CAN communication...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com