Method for detecting evaporation process of droplet particles and measuring evaporation rate of droplet particles

A technology of evaporation rate and measurement method, which is applied in measurement devices, particle size analysis, particle and sedimentation analysis, etc. It can solve the problems affecting the measurement accuracy of droplet evaporation rate and inaccurate particle diameter, and achieve strong practicability and high measurement accuracy. , the effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the purpose, technical solution and advantages of the present invention clearer, the implementation manners of the present invention will be further described in detail below.

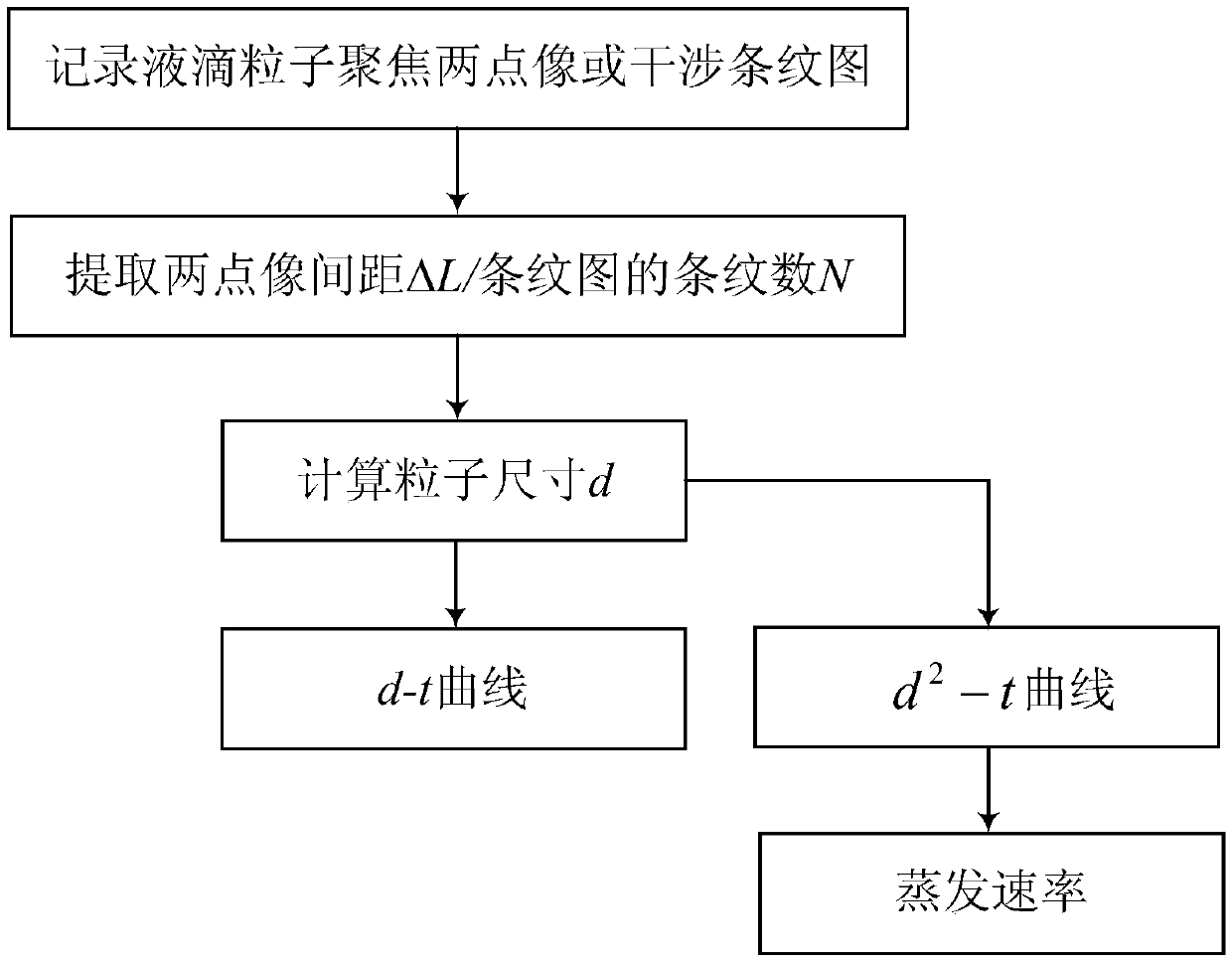

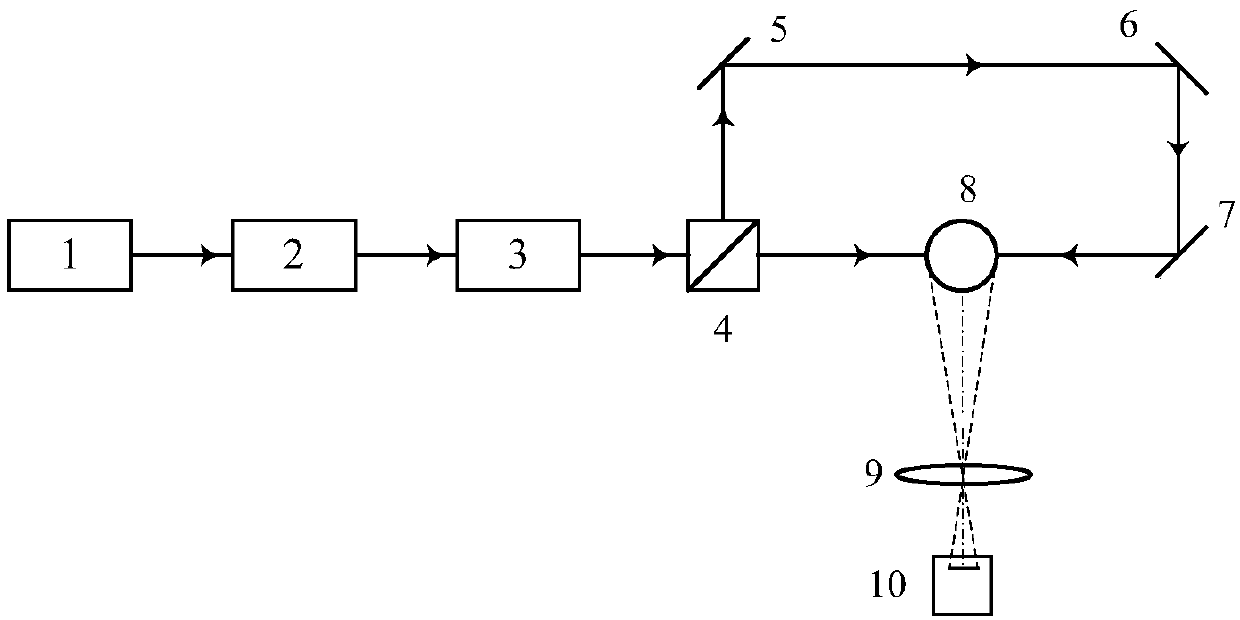

[0022] A kind of detection method of droplet particle evaporation process and its evaporation rate, see figure 1 and figure 2 , the measurement method includes the following steps:

[0023] 1. Build the optical system

[0024] according to figure 2 Build an optical path system, including: laser 1, beam expander collimation system 2, beam compression system 3, beam splitter 4, first mirror 5, second mirror 6 and third mirror 7, particles 8, imaging lens 9 , CCD 10.

[0025] Laser 1 is a vertically polarized semiconductor laser with a wavelength of λ=532nm and a maximum power of 1.5W. The thin beam emitted by the laser 1 is expanded, filtered, and collimated by the beam expander and collimator system 2 to form a circular beam with a diameter of 20mm;

[0026] Then the beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com