Method for predicting fatigue strength of metal material by hardening strength and tensile strength

A technology of tensile strength and hardening strength, applied in the analysis of materials, strength characteristics, and the use of stable tension/pressure to test the strength of materials, etc. The effect of time, less time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment is to carry out fatigue strength prediction to the 316L steel material of different tensile strength, test (experimental data) to 316L steel material of 4 kinds of different tensile strengths, and be used for predicting 3 kinds of 316L steel materials (verification) of remaining untested data).

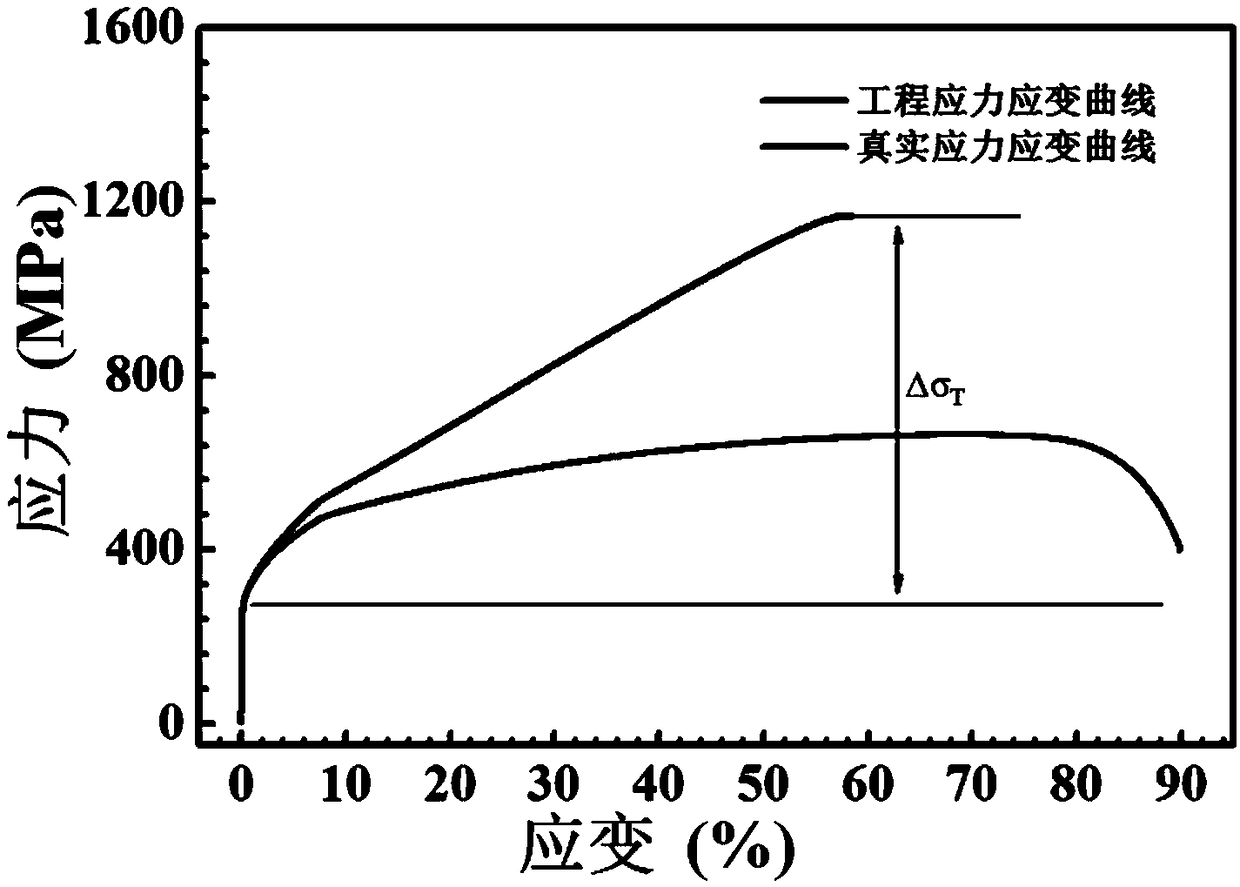

[0028] Step 1: Conduct axial tensile experiments on tensile samples of 316L steel materials with different tensile strengths, and obtain engineering stress-strain curves and tensile strengths of 316L steel materials with different tensile strengths. figure 1 It is the relationship between engineering stress-strain curve, real stress-strain curve and hardening strength of 316L steel material.

[0029] The four kinds of 316L steel materials used have tensile strengths of 1363MPa, 1170MPa, 904MPa and 667MPa respectively.

[0030] Step 2: Transform the engineering stress-strain curves in step 1 into true stress-strain curves according to formulas (2)-(3), and calcu...

Embodiment 2

[0034] This embodiment is to predict the fatigue strength of TWIP steel materials with different tensile strengths.

[0035] Step 1: Carry out axial tensile experiments on TWIP steel tensile samples with different tensile strengths, obtain engineering stress-strain curves of TWIP steel materials with different tensile strengths and four kinds of TWIP steel materials used for tensile strength, tensile strength The strengths are 1600MPa, 1443MPa, 1200MPa and 952MPa respectively.

[0036] Step 2: Transform the engineering stress-strain curves in step 1 into true stress-strain curves according to formulas (2)-(3), and calculate the hardening strength. The hardening strengths of the four TWIP steel materials used are 237MPa, 409MPa, 827MPa and 1462MPa, respectively.

[0037] Step 3: Carry out high-cycle fatigue test to obtain fatigue strength. According to the formula (1), the hardening strength in step 2 and the tensile strength in step 1 are substituted and fitted to obtain the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com