A radial well guiding plugging agent injection oil well water plugging method

A technology for oil well water plugging and radial wells, which is applied in wellbore/well components, earthwork drilling, sealing/isolation, etc. It can solve the problems of increasing operation difficulty and cost, high injection pressure, and inability of plugging agents to enter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0080] 1. Method description

[0081] (1) Determination of radial well orientation

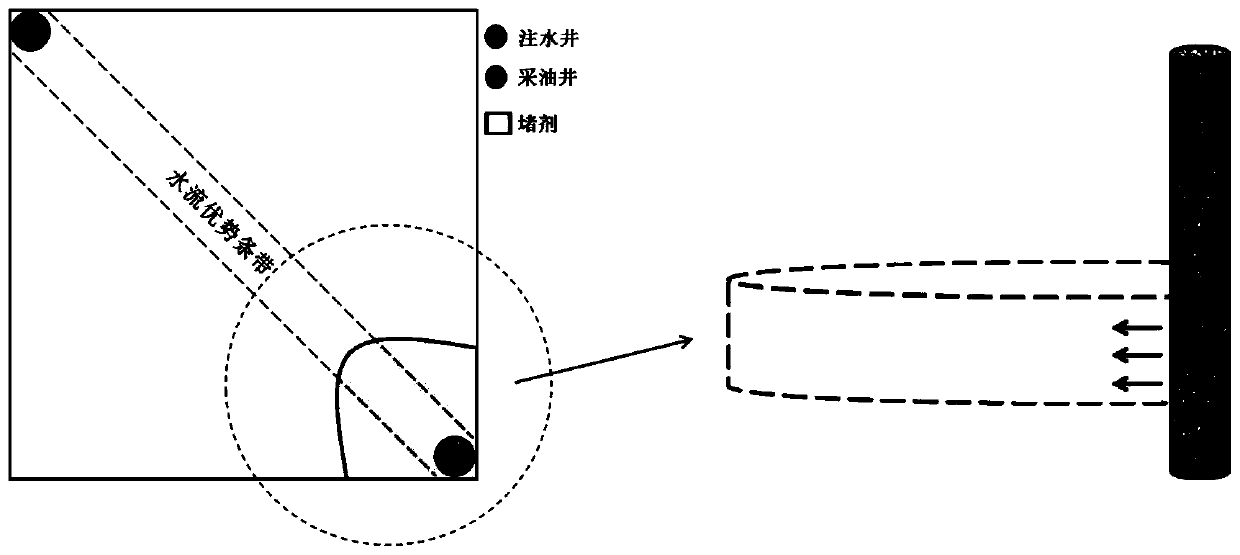

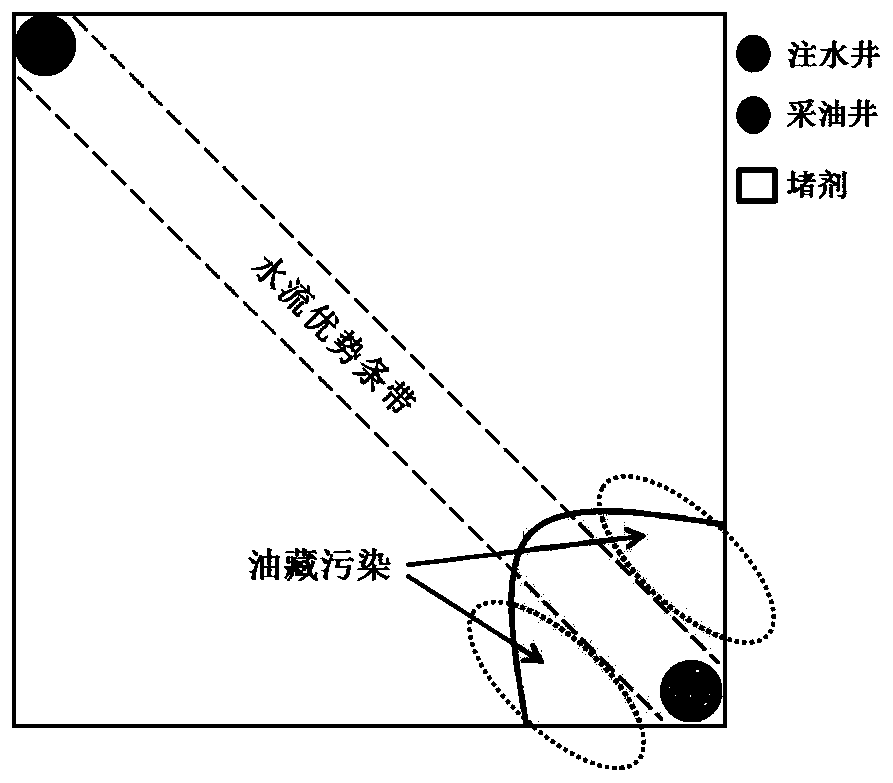

[0082] Using engineering methods (tracer method, PI isovalue map description method, log curve characteristic ratio judgment method, etc.) to determine the orientation of the dominant water flow zone in the formation, the orientation of the radial well is consistent with the orientation of the dominant water flow zone.

[0083] (2) Determination of radial well length

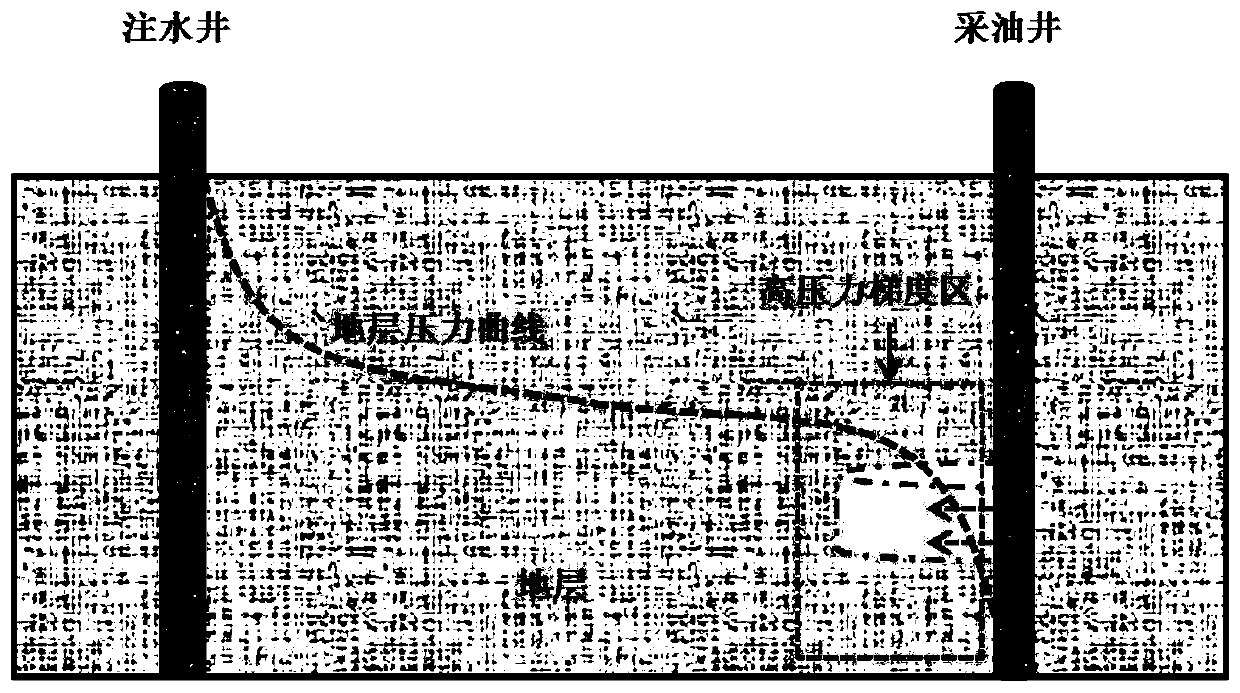

[0084] The pressure distribution in the formation shows the characteristics of large pressure gradient between water injection well and oil production well, and small pressure gradient in the deep formation (such as Figure 4 shown). The strength of the plugging agent selected for oil well water plugging must at least be able to withstand the pressure gradient of the formation around the oil we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com