Ultra-long combined square drill rod and machining methods thereof

A processing method and kelly technology, which is applied in the direction of drill pipe, earthwork drilling, drill pipe, etc., can solve the problems of inability to realize integral structure and length exceeding the processing range, etc., so as to improve drilling efficiency and drilling depth , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further elaborated and illustrated below in conjunction with specific embodiments and accompanying drawings.

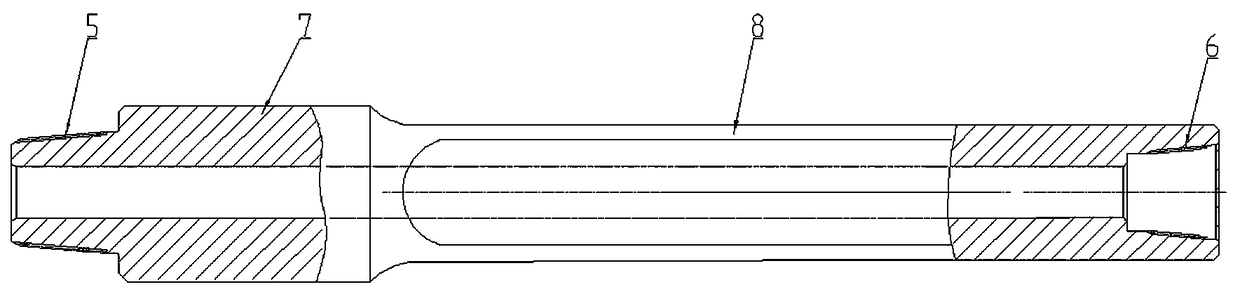

[0025] See attached figure 1 , 2 , an ultra-long combined square kelly, comprising an upper kelly and a lower kelly, both of which are hollow structures and both of which are composed of a joint end and a milled square end , the upper kelly milling square end 4 is threadedly connected to the lower kelly milling square end 6, and an upper kelly internal thread of type 6 5 / 8REG-LH is provided in the front end of the upper kelly joint end 3 1. At the rear end of the upper kelly milling square end 4, there is an upper kelly double shoulder external thread 2 of model ZYNC46, the length of the upper kelly is 13625 mm, and the lower kelly The front end of the joint end 7 is provided with a lower kelly external thread 5 of model 5 1 / 2FH, and the lower kelly milling square end 8 is provided with a lower kelly double-shoulder internal thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com