Lignin surface sizing agent and preparation method thereof

A technology of surface sizing agent and lignin, which is applied in the preparation of lignin surface sizing agent and the field of lignin surface sizing agent, can solve the problems of high cost, large amount of sizing agent, and difficulty in improving grades, etc. Achieve the effect of being suitable for large-scale industrial production, improving the surface ring crush strength, and improving the Cobb value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

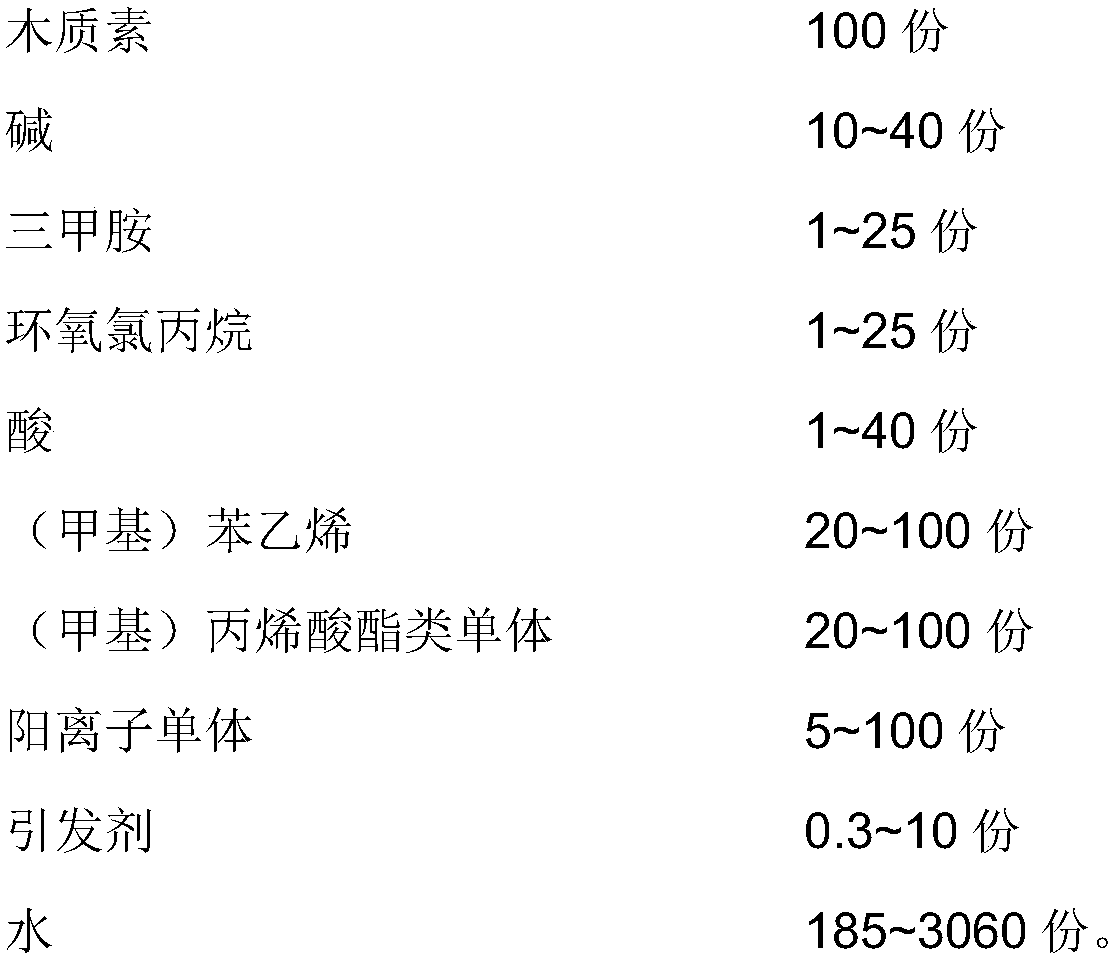

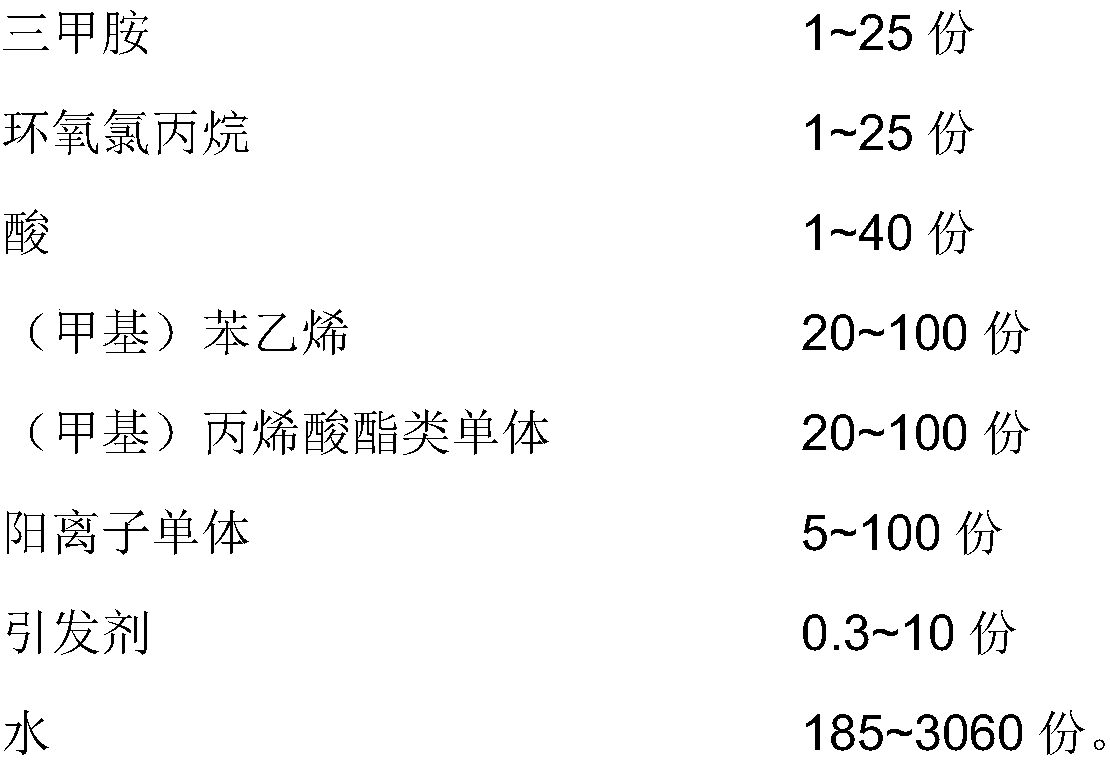

Method used

Image

Examples

Embodiment 1

[0033] Prepare lignin surface sizing agent ① according to the following steps:

[0034] Step A): Mix 20 grams of styrene, 20 grams of n-butyl acrylate, and 5 grams of N,N-dimethylaminoethyl acrylate, and set aside;

[0035] Step B): Dissolve 0.3 g of ammonium persulfate in 10 g of deionized water for use;

[0036] Step C): Add 148.3 grams of deionized water, 10 grams of potassium hydroxide, 1 gram of trimethylamine, and 100 grams of lignin into a four-necked flask equipped with a condenser, a dripping device, a stirrer and a thermometer. After it is completely dissolved Increase the temperature to 45°C, add 1 gram of epichlorohydrin dropwise, the dropping time is 0.25 hours, and the temperature is continued for 0.75 hours; the temperature is increased to 70°C, and 1 gram of hydrochloric acid is added; The dripping time is 1 hour; at the same time, the initiator aqueous solution prepared in step B) is dripped, and the dripping time is 1 hour; after the dripping, the reaction is kept ...

Embodiment 2

[0038] Prepare lignin surface sizing agent ② according to the following steps:

[0039] Step A): Mix 100 grams of methyl styrene, 100 grams of isooctyl acrylate, and 100 grams of methacrylamide propyl dimethyl amine, and set aside;

[0040] Step B): Dissolve 10 grams of sodium persulfate in 100 grams of deionized water for use;

[0041] Step C): Add 2960 grams of deionized water, 40 grams of ammonium hydroxide, 25 grams of trimethylamine, and 100 grams of lignin in a four-necked flask equipped with a condenser, a dripping device, a stirrer, and a thermometer. Warm up to 55°C, add 25 grams of epichlorohydrin dropwise, dropwise for 1 hour, continue to keep for 2 hours; warm up to 95°C, add 40 grams of dilute sulfuric acid; add dropwise the mixed monomer prepared in step A) at 95°C , The dripping time is 3 hours; the initiator aqueous solution prepared in step B) is dripped at the same time, the dripping time is 3 hours; after the dripping, the reaction is kept at 95°C for 2 hours, and...

Embodiment 3

[0043] Prepare lignin surface sizing agent ③ according to the following steps:

[0044] Step A): Mix 60 grams of methyl styrene, 50 grams of ethyl methacrylate, and 50 grams of methacrylamide propyl dimethyl amine, and set aside;

[0045] Step B): Dissolve 6 grams of hydrogen peroxide in 100 grams of deionized water for use;

[0046] Step C): Add 684 grams of deionized water, 20 grams of sodium hydroxide, 15 grams of trimethylamine, and 100 grams of lignin into a four-necked flask equipped with a condenser, a dripping device, a stirrer and a thermometer. Raise the temperature to 65°C, add 15 grams of epichlorohydrin dropwise, add dropwise for 2 hours, and continue to keep the temperature for 1 hour; raise the temperature to 85°C, add 20 grams of acetic acid; add dropwise the mixed monomer prepared in step A) at 85°C, The dripping time is 1.5 hours; the initiator aqueous solution prepared in step B) is dripped at the same time, and the dripping time is 2 hours; after the dripping is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com