Integrated full closed-loop ecological circular agriculture system and operation technology thereof

An ecological cycle and full-closed-loop technology, applied in the direction of gas production bioreactors, biochemical instruments, biomass post-processing, etc., can solve the problems of high energy and raw material consumption, low economic performance, etc., to reduce investment costs and system operation Energy consumption and the effect of ensuring fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

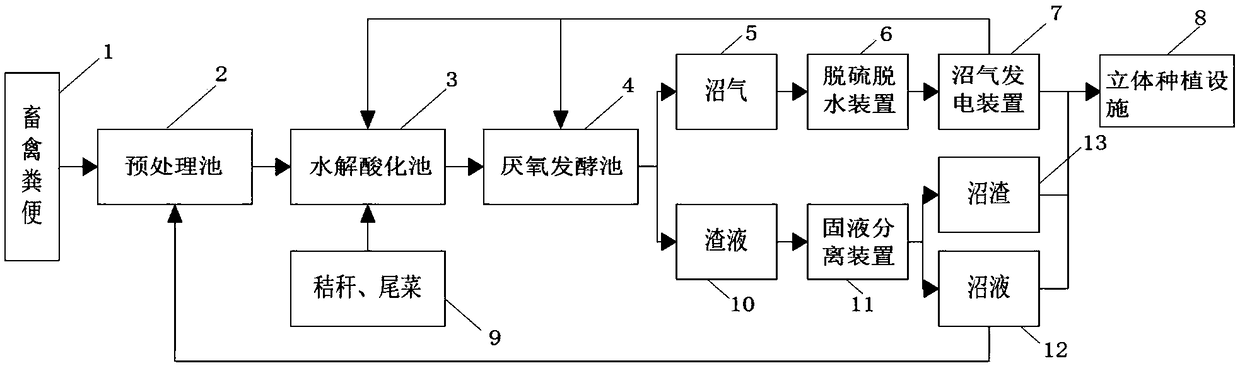

[0033] This embodiment provides an integrated fully closed-loop ecological cycle agricultural system, such as figure 1 As shown, the integrated fully closed-loop ecological cycle agricultural system includes a three-dimensional planting facility 8 built on the ground. The three-dimensional planting facility 8 in this embodiment can be any three-dimensional agricultural facility in the prior art, such as building on the ground The greenhouse above is provided with a three-dimensional frame for three-dimensional planting of crops in the greenhouse.

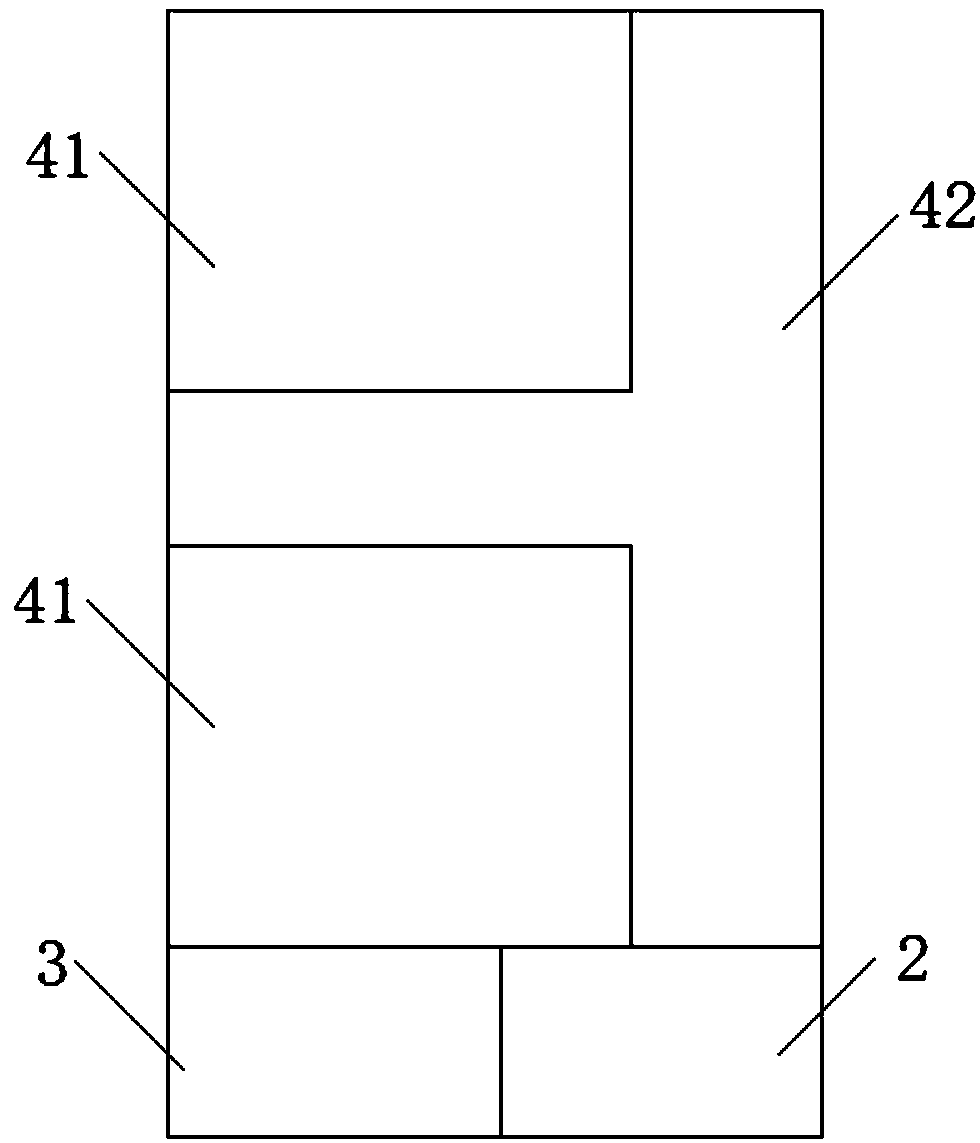

[0034] The agricultural system in this embodiment also includes an anaerobic fermentation subsystem arranged underground, such as figure 2 As shown, the anaerobic fermentation subsystem further includes a hydrolytic acidification tank 3 and an anaerobic fermentation tank 4 arranged in series, and the anaerobic fermentation zone 41 and pipelines and corridors 42 of the anaerobic fermentation tank 4 are all arranged underground; The a...

Embodiment 2

[0048] The integrated fully closed-loop ecological cycle agricultural system in this embodiment is the same as that in Embodiment 1, and this embodiment provides an optimized operation process of the integrated fully closed-loop ecological cycle agricultural system. The operation technique in the present embodiment comprises:

[0049] (1) Measuring the livestock and poultry manure 1 into the pretreatment tank 2, mixing it with the regulated water, and then carrying out the sedimentation and impurity removal treatment, the TS content of the livestock and poultry manure 1 in the pretreatment tank 2 after adding the regulated water is 6wt %, the pH value of the liquid in the pretreatment tank 2 is adjusted to 6.5-7.5;

[0050] Send the livestock and poultry manure 1 after sedimentation and removal of impurities together with the straw and tail vegetables 9 that have been crushed to a length of 3-5 cm into the hydrolysis acidification tank 3, and the residence time of the mixed ma...

Embodiment 3

[0056] The integrated full-closed-loop ecological cycle agricultural system in this embodiment is the same as that in Embodiment 2, and the operation process in this embodiment includes:

[0057] (1) Enter the pretreatment tank 2 after the livestock and poultry manure 1 is measured, and carry out the sedimentation and impurity removal treatment after mixing with the regulating water. The TS content of the livestock and poultry manure 1 in the pretreatment pond 2 after adding the regulating water is 5wt %, the pH value of the liquid in the pretreatment tank 2 is adjusted to 6.5-7.5;

[0058] Send the livestock and poultry excrement 1 after sedimentation and removal of impurities together with the stalks and tail vegetables 9 that have been crushed to 3-5cm long into the hydrolytic acidification tank 3, and the residence time of the mixed material in the hydrolytic acidification tank 3 is 3 days; the mixed material Pumped to the anaerobic fermentation tank 4 to enter the gas pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com