Clean and environment-friendly type compound thickening agent for fracturing fluid and preparation method

A compound thickener, clean and environmentally friendly technology, applied in chemical instruments and methods, drilling compositions, other chemical processes, etc., can solve the problems of low viscosity, low gel strength, etc., achieve less system, easy to degrade, The effect of the value of good practical application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] In yet another specific embodiment of the present invention, the preparation method of the aminohydroxyethyl polyacrylamide comprises:

[0052] (1) Slowly add glyoxal into the aqueous solution of polyacrylamide at 45-55°C until the mixture is completely uniform, and keep it in this temperature range for 1.5-2.5 hours to obtain an aqueous solution of hydroxyethyl polyacrylamide;

[0053] (2) Slowly add ethylenediamine to the aqueous solution of hydroxyethyl polyacrylamide prepared in step (1) at 45-55°C until the mixture is completely uniform, and then react at 75-85°C for 2.5-3.5 hours to obtain amine Hydroxyethyl polyacrylamide.

[0054] In yet another specific embodiment of the present invention, in the step (1),

[0055] The polyacrylamide aqueous solution is 1%~3% (mass fraction) polyacrylamide aqueous solution (preferably 2%);

[0056] The molar ratio of polyacrylamide to glyoxal is 1 to 3:1 (preferably 2:1);

[0057] In yet another specific embodiment of the pr...

Embodiment 1

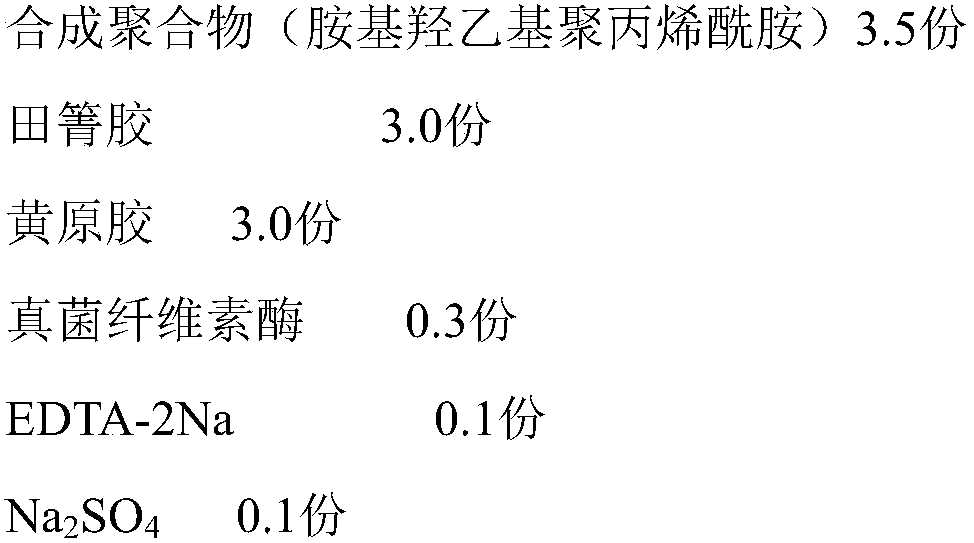

[0080] 1. The formula of the compound thickener for clean and environment-friendly fracturing fluid is as follows, in parts by mass:

[0081]

[0082] 2. Synthetic method of synthetic polymer (amino hydroxyethyl polyacrylamide)

[0083] A. Make polyacrylamide into a 2% aqueous solution, add glyoxal to the 2%-polyacrylamide aqueous solution, and the molar ratio of polyacrylamide to glyoxal is 1:0.5. Add glyoxal to the aqueous solution of polyacrylamide dropwise at 50°C until the mixture is completely uniform, and keep at 50(±5)°C for 2 hours to obtain an aqueous solution of hydroxyethyl polyacrylamide.

[0084] B. Add ethylenediamine to hydroxyethyl polyacrylamide (the molar ratio of ethylenediamine to hydroxyethyl polyacrylamide is 1:1), and dropwise add ethylenediamine to the hydroxyethyl group in step A at 50°C In the polyacrylamide aqueous solution, react at 80 (±5)°C for 3 hours until the mixture is completely uniform to prepare aminohydroxyethyl polyacrylamide.

[00...

Embodiment 2

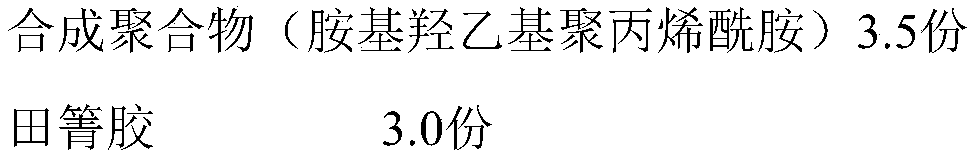

[0089] 1. The formula of the compound thickener for clean and environment-friendly fracturing fluid is as follows, according to the mass fraction,

[0090]

[0091] 2. Synthetic method of synthetic polymer (amino hydroxyethyl polyacrylamide)

[0092] A. Make polyacrylamide into a 4% aqueous solution, add glyoxal to the 4% polyacrylamide aqueous solution, and the molar ratio of polyacrylamide to glyoxal is 1:0.5. Add glyoxal to the aqueous solution of polyacrylamide dropwise at 50°C until the mixture is completely uniform, and keep at 50(±5)°C for 2 hours to obtain an aqueous solution of hydroxyethyl polyacrylamide.

[0093] B. Add ethylenediamine to hydroxyethyl polyacrylamide (the molar ratio of ethylenediamine to hydroxyethyl polyacrylamide is 1:1), and dropwise add ethylenediamine to the hydroxyethyl group in step A at 50°C In the polyacrylamide aqueous solution, react at 80 (±5)°C for 3 hours until the mixture is completely uniform to prepare aminohydroxyethyl polyacry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com