Cloud rhyolitic plastic product processing method taking ABS as base material

A technology for ABS plastics and plastic products, which is applied in the field of cloud flow pattern plastic products processing, can solve the problems of prominent surface cracks and insufficient compatibility of plastic products, and achieve the effects of enhancing mechanical properties, gorgeous appearance, and improving interface adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

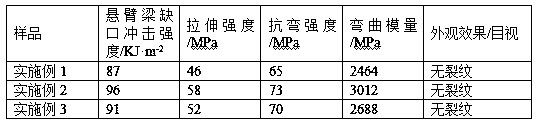

Examples

Embodiment 1

[0021] a. Take 60% of ABS plastic pellets, 15% of mica, 15% of modified glass fiber, 8% of compatibilizer ABS-g-MAH, 1% of SBS elastomer, 0.8% of zinc stearate and antioxidant Agent 1010 is 0.2%;

[0022] b. Add the cloud color masterbatch to the side feeding hopper of the twin-screw extruder, add other raw materials to the main hopper, and extrude the mixed material strip through the twin-screw extruder. The temperatures are: 185°C, 190°C, 200°C, 210°C, 220°C and 220°C, the speed of the control host screw is 275r / min, the speed of the main hopper feed screw is 30r / min, and the speed of the side feed feed screw The speed is 8r / min;

[0023] c. Cool, dry and pelletize the mixed material strip extruded by the twin-screw extruder to obtain the ABS composite material with cloud flow pattern;

[0024] d. Add the ABS composite material into the injection molding machine for injection, set the injection temperature of the injection molding machine to 240°C, the injection pressure t...

Embodiment 2

[0026] a. Take 71% of ABS plastic pellets, 10% of mica, 11% of modified glass fiber, 5% of compatibilizer ABS-g-MAH, 2% of SBS elastomer, 0.8% of zinc stearate and antioxidant Agent 1010 is 0.2%;

[0027] b. Add the cloud color masterbatch to the side feeding hopper of the twin-screw extruder, add other raw materials to the main hopper, and extrude the mixed material strip through the twin-screw extruder. The temperatures are: 180°C, 190°C, 200°C, 210°C, 215°C and 220°C, the speed of the control host screw is 230r / min, the speed of the main hopper feed screw is 30r / min, and the speed of the side feed feed screw The speed is 6r / min;

[0028] c. Cool, dry and pelletize the mixed material strip extruded by the twin-screw extruder to obtain the ABS composite material with cloud flow pattern;

[0029] d. Add the ABS composite material into the injection molding machine for injection, set the injection temperature of the injection molding machine to 240°C, the injection pressure t...

Embodiment 3

[0031] a. Take 63% of ABS plastic pellets, 14% of mica, 14% of modified glass fiber, 6% of compatibilizer ABS-g-MAH, 1.5% of SBS elastomer, 1.1% of zinc stearate and antioxidant Agent 1010 is 0.4%;

[0032] b. Add the cloud color masterbatch to the side feeding hopper of the twin-screw extruder, add other raw materials to the main hopper, and extrude the mixed material strip through the twin-screw extruder. The temperatures are: 170°C, 185°C, 195°C, 210°C, 220°C and 220°C, the speed of the control host screw is 320r / min, the speed of the main hopper feed screw is 30r / min, and the speed of the side feed feed screw The speed is 10r / min;

[0033] c. Cool, dry and pelletize the mixed material strip extruded by the twin-screw extruder to obtain the ABS composite material with cloud flow pattern;

[0034] d. Put the ABS composite material into the injection molding machine for injection, set the injection temperature of the injection molding machine to 238°C, the injection pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com