UV printing process for color packaging box

A packing box and color technology, applied in the printing process, printing, printing post-processing, etc., can solve the problems of unable to float the pattern, poor three-dimensional effect, etc., and achieve the effect of gorgeous appearance and good three-dimensional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

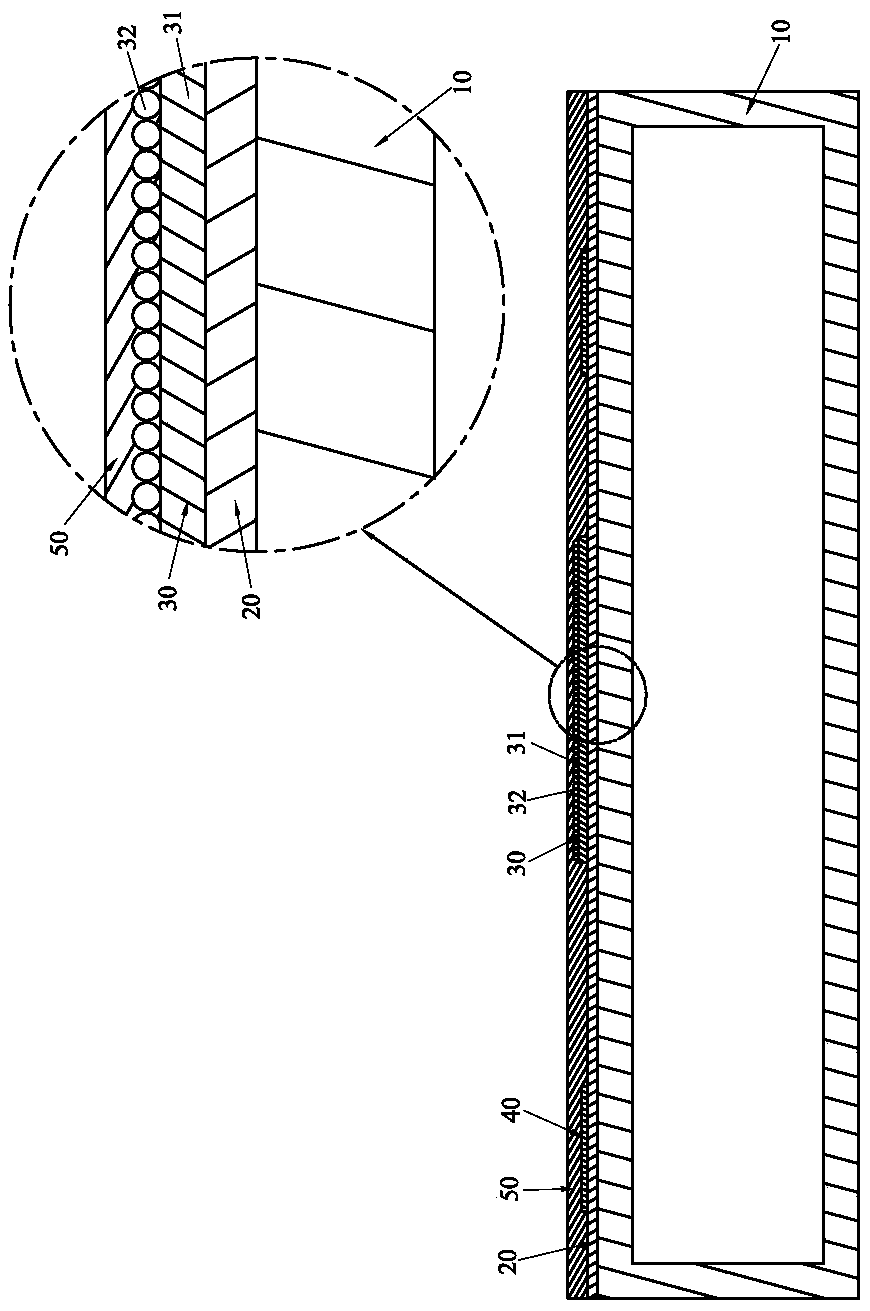

[0025] The invention discloses a UV printing process for color packaging boxes, including the following steps:

[0026] (1) Take the box blank 10, use the first screen to print the color ink on the entire surface area of the box blank 10, and use the UV lamp group to cure the printed color ink to form the background pattern layer 20; in this embodiment Among them, the color ink includes the following components by weight: 10-16 parts of acrylate oligomer, 50-80 parts of diluent, 5-10 parts of photoinitiator, 10-15 parts of color pigment, wetting fluid 0.8-1.5 parts of flat defoaming agent; 0.5-0.8 parts of polymerization inhibitor, and the acrylate oligomer is a polyacrylate with side chain carboxyl group, and the diluent is difunctional hexane with extremely low absolute viscosity. Diol diacrylate, the photoinitiator is a photoinitiator whose absorption peak is close to the absorption trough of the pigment, and the blue UV color ink uses a free radical cracking type photoin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com