A cellulose-based temperature-sensitive conductive hydrogel and its preparation method and application

A temperature-sensitive, conductive hydrogel technology, which is applied in the field of fiber material preparation, can solve the problems of weakened stimulus responsiveness and weakened mechanical properties of hydrogels, and achieve excellent electrical conductivity, excellent mechanical properties, and unique thermal properties. The effect of responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

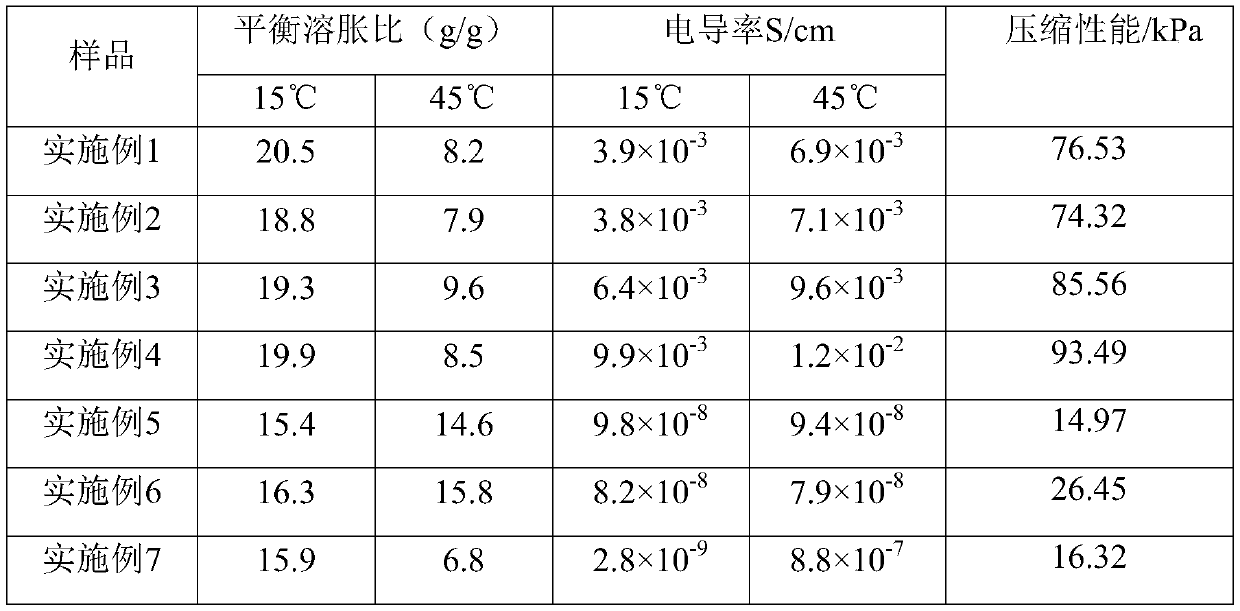

Examples

Embodiment 1

[0029] This embodiment provides a cellulose-based temperature-sensitive conductive hydrogel, the preparation method comprising the following steps:

[0030] (1) Weigh 15g of cellulose solution, add 1mL of 2wt% guar gum solution and 1mL of epichlorohydrin, stir at 30°C for 30 minutes, and then heat at 60°C for 30 minutes to obtain a cellulose-based hydrogel. Soak the cellulose-based hydrogel in excess glacial acetic acid for 12 hours, take out the above-mentioned cellulose-based hydrogel and soak it in a In the aqueous solution, the quality of NIPAAm, BIS and water in this aqueous solution is 0.10g, 0.006g and 4g respectively, pass through inert gas for 30 minutes, stand for 5 hours, add 0.12g of ammonium persulfate (APS) and continue to pass through nitrogen 10 minutes, react at 50°C for 8 hours. The gel formed by cross-linking was taken out, placed in a dialysis bag, immersed in deionized water, changed every 12 hours, and dialyzed for 6 days to remove impurity ions.

[003...

Embodiment 2

[0033] This embodiment provides a cellulose-based temperature-sensitive conductive hydrogel, the preparation method comprising the following steps:

[0034](1) Weigh 15g of cellulose solution, add 1mL of 2wt% guar gum solution and 1mL of epichlorohydrin, stir at 30°C for 30 minutes, and then heat at 60°C for 30 minutes to obtain a cellulose-based hydrogel. Soak the cellulose-based hydrogel in excess glacial acetic acid for 12 hours, take out the above-mentioned cellulose-based hydrogel and soak it in a In the aqueous solution, the quality of NIPAAm, BIS and water in this aqueous solution is 0.10g, 0.008g and 4g respectively, pass through inert gas for 30 minutes, stand for 5 hours, add 0.12g of ammonium persulfate (APS) and continue to pass through nitrogen 10 minutes, react at 50°C for 8 hours. The gel formed by cross-linking was taken out, placed in a dialysis bag, immersed in deionized water, changed every 12 hours, and dialyzed for 6 days to remove impurity ions.

[0035...

Embodiment 3

[0037] This embodiment provides a cellulose-based temperature-sensitive conductive hydrogel, the preparation method comprising the following steps:

[0038] (1) Weigh 15g of cellulose solution, add 1mL of 2wt% guar gum solution and 1mL of epichlorohydrin, stir at 30°C for 30 minutes, and then heat at 60°C for 30 minutes to obtain a cellulose-based hydrogel. Soak the cellulose-based hydrogel in excess glacial acetic acid for 12 hours, take out the above-mentioned cellulose-based hydrogel and soak it in a In the aqueous solution, the quality of NIPAAm, BIS and water in this aqueous solution is 0.10g, 0.008g and 4g respectively, pass through inert gas for 30 minutes, stand for 5 hours, add 0.12g of ammonium persulfate (APS) and continue to pass through nitrogen 10 minutes, react at 50°C for 8 hours. The gel formed by cross-linking was taken out, placed in a dialysis bag, immersed in deionized water, changed every 12 hours, and dialyzed for 6 days to remove impurity ions.

[003...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| compressive stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com