A kind of dopo-phthalimide derivative, preparation method and application

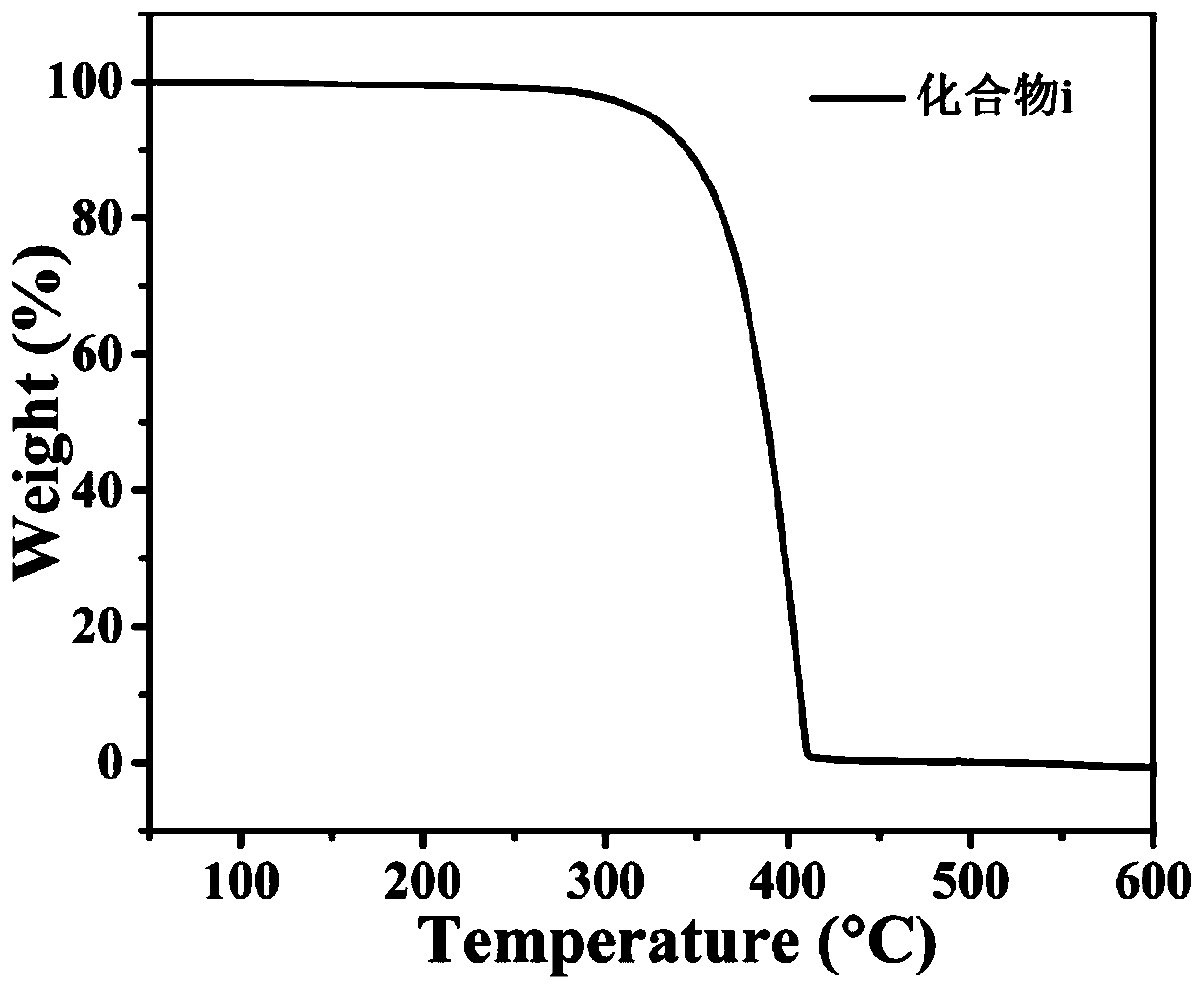

A technology of phthalimide and derivatives is applied in the field of flame retardant modification of polymer materials to achieve the effects of high thermal stability, satisfying processing conditions and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

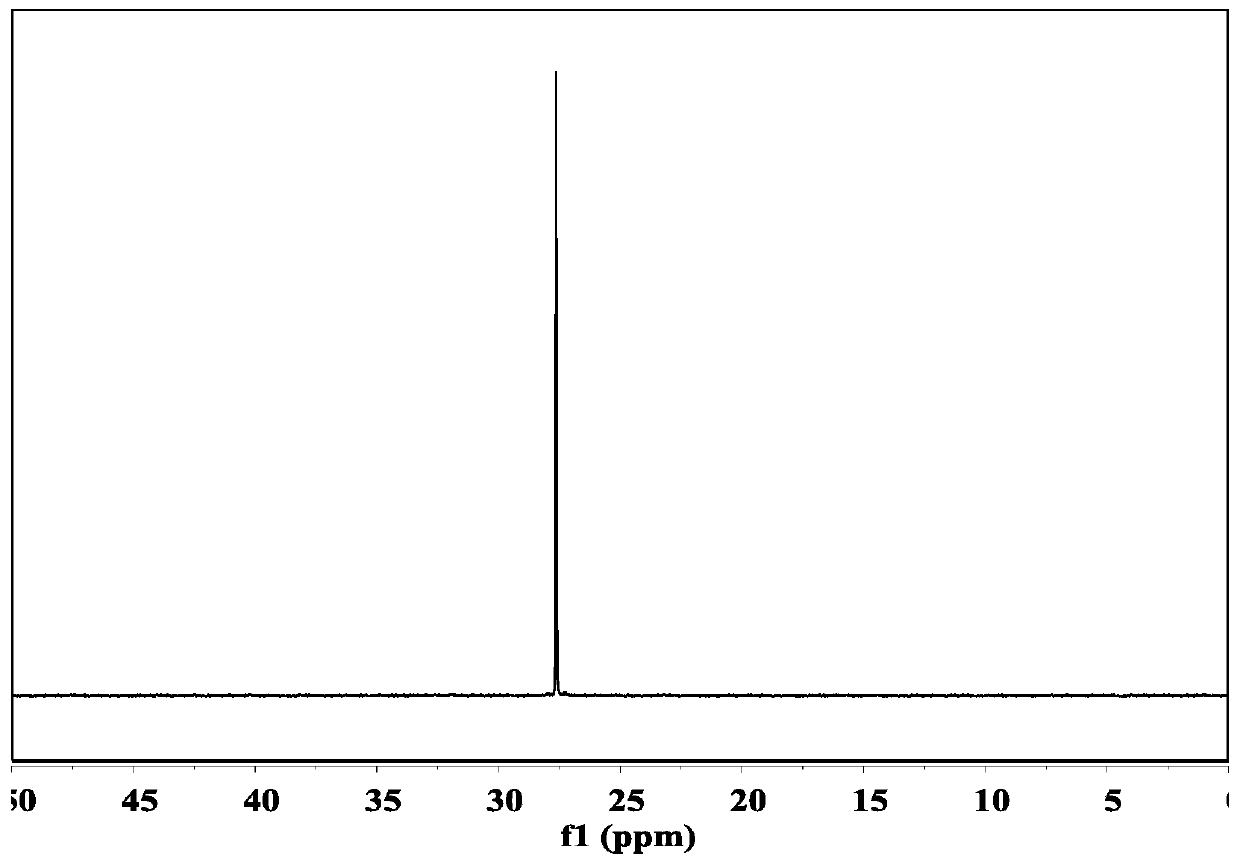

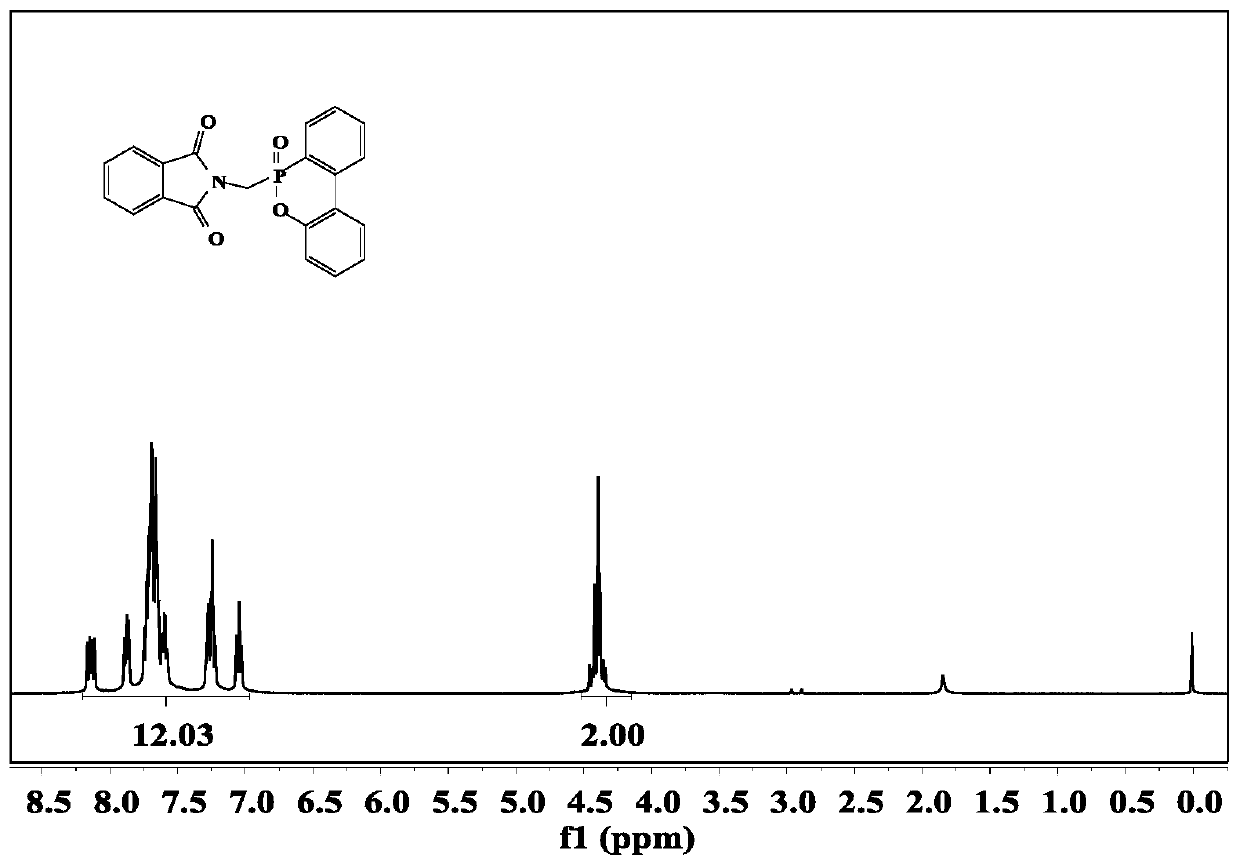

[0076] There is the preparation of formula (I-i) structure compound

[0077] (1) DOPO (162.00 g, 0.75 mol) and 200 ml of xylene were added to a three-necked flask equipped with a thermometer, a magnetic stir bar, and a spherical condenser. Under the protection of nitrogen, the temperature of the system was slowly raised to 95°C. After the system was completely transparent, 22.50 g of paraformaldehyde was added in batches within 3 hours. After feeding, the temperature was continued to stir and react for 6 hours. Suction filtration while hot, the obtained solid was dried under vacuum at 80° C. for 8 hours to obtain 179 g of product with a yield of 97.0%.

[0078] (2) Weigh 116.03 g (0.47 mol) of the adduct of DOPO and paraformaldehyde, and add 300 ml of pyridine into a three-neck flask equipped with a thermometer and a magnetic stir bar. Then 180.10 g (0.94 mol) of p-toluenesulfonyl chloride were added slowly over 1 hour. Stir overnight at 25°C. Suction filtration, washin...

Embodiment 2

[0083] There is the preparation of formula (I-i) structure compound

[0084] (1) DOPO (162.00 g, 0.75 mol) and 200 ml of benzene were added to a three-necked flask equipped with a thermometer, a magnetic stir bar, and a spherical condenser. Under the protection of nitrogen, the temperature of the system was slowly raised to 70°C. 27 g of paraformaldehyde were added in portions over 4 hours. After feeding was completed, the stirring reaction was continued for 8 hours at this temperature. Suction filtration while hot, the obtained solid was dried under vacuum at 80° C. for 8 hours to obtain 181 g of product with a yield of 98.0%.

[0085](2) Weigh 116.03 g (0.47 mol) of the above-mentioned DOPO-alcohol compound, and add 300 ml of picoline into a three-necked flask equipped with a thermometer and a magnetic stir bar. Under the condition of ice bath, 114.90 g (0.60 mol) p-toluenesulfonyl chloride was slowly added. After feeding, the temperature of the reaction system will ri...

Embodiment 3

[0088] There is the preparation of formula (I-i) structure compound

[0089] (1) DOPO (162.00 g, 0.75 mol) and 200 ml of cyclohexane were added to a three-necked flask equipped with a thermometer, a magnetic stir bar, and a spherical condenser. Under the protection of nitrogen, the temperature of the system was slowly raised to 70°C. 24.75 grams of paraformaldehyde were added in portions over 4 hours. After the feeding was completed, the stirring reaction was continued for 15 hours at this temperature. Suction filtration while hot, the obtained solid was dried under vacuum at 80° C. for 8 hours to obtain 175 g of product with a yield of 95.0%.

[0090] (2) Weigh 116.03 g (0.47 mol) of the adduct of DOPO and paraformaldehyde, add 200 ml of pyridine and 100 ml of triethylamine into a three-necked flask equipped with a thermometer and a magnetic stir bar. Then 180.10 g (0.94 mol) of p-toluenesulfonyl chloride were added slowly over 1 hour. Stir overnight at 25°C. Suction f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com