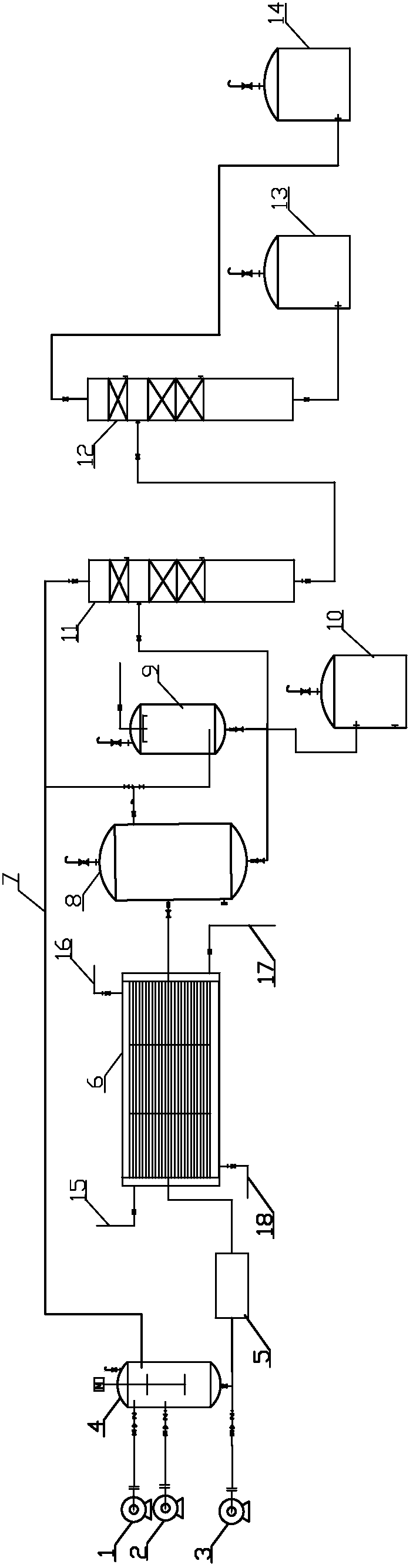

Technology and device for preparing chloroacetic acid through catalytic chlorination by means of micro-channel reactor

A microchannel reactor, chloroacetic acid technology, applied in the field of chloroacetic acid, can solve the problems of high equipment investment, high operating cost, easy generation of temperature difference, etc., and achieve the effects of improving reaction efficiency, reducing operating cost, and reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Put 500kg of acetic acid and 65kg of acetic anhydride into the mixer for pretreatment for 15 minutes to form a mixed solution, then mix the mixed solution with 590kg of liquid chlorine in the pipeline before the precatalytic tank, and enter the inner wall with a solid acid catalyst SO4 2- / ZrO 2 -Eu 2 o 3 The pre-catalytic reaction is carried out in the pre-catalytic tank; the pre-catalytic tank is controlled at normal pressure, the temperature is 75°C, and the reaction residence time is 10s; the solid acid catalyst SO4 on the inner wall of the pre-catalytic tank 2- / ZrO 2 -Eu 2 o 3 The thickness of the coating was 5 mm.

[0031] Then enter the inner wall of the microchannel with solid acid catalyst SO4 2- / ZrO 2 -Eu 2 o 3 Catalytic chlorination reaction is carried out in the microchannel reactor to obtain the chloroacetic acid reaction solution; the microchannel reaction system is controlled at a pressure of 0.35MPa, a temperature of 90°C, and a reaction resid...

Embodiment 2

[0034] Put 500kg of acetic acid and 42kg of acetic anhydride into the mixer for pretreatment for 10 minutes to form a mixed solution, then mix the mixed solution with 620kg of liquid chlorine in the pipeline before the precatalytic tank, and enter the inner wall with a solid acid catalyst SO4 2- / ZrO 2 -Eu 2 o 3 The pre-catalytic reaction is carried out in the pre-catalytic tank; the pre-catalytic tank is controlled at normal pressure, the temperature is 50°C, and the reaction residence time is 100s; the solid acid catalyst SO4 on the inner wall of the pre-catalytic tank 2- / ZrO 2 -Eu 2 o 3 The thickness of the coating was 7 mm.

[0035] Then enter the inner wall of the microchannel with solid acid catalyst SO4 2- / ZrO 2 -Eu 2 o 3 Catalytic chlorination reaction is carried out in the microchannel reactor to obtain the chloroacetic acid reaction solution; the microchannel reaction system is controlled at a pressure of 0.4MPa, a temperature of 80°C, and a reaction resid...

Embodiment 3

[0038] Put 500kg of acetic acid and 80kg of acetic anhydride into the mixer for pretreatment for 20 minutes to form a mixed solution, then mix the mixed solution with 610kg of liquid chlorine in the pipeline before the precatalytic tank, and enter the inner wall with a solid acid catalyst SO4 2- / ZrO 2 -Eu 2 o 3 The pre-catalytic reaction is carried out in the pre-catalytic tank; the pre-catalytic tank is controlled at normal pressure, the temperature is 60°C, and the reaction residence time is 50s; the solid acid catalyst SO4 on the inner wall of the pre-catalytic tank 2- / ZrO 2 -Eu 2 o 3 The thickness of the coating was 6 mm.

[0039] Then enter the inner wall of the microchannel with solid acid catalyst SO4 2- / ZrO 2 -Eu 2 o 3 Catalytic chlorination reaction is carried out in the microchannel reactor to obtain the chloroacetic acid reaction solution; the microchannel reaction system is controlled at a pressure of 0.3MPa, a temperature of 95°C, and a reaction reside...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com