Industrial sludge deep dehydration conditioning agent and preparation method and application thereof

A technology for deep dehydration and industrial sludge, applied in water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, chemical instruments and methods, etc. Deal with high cost, endanger human health and other problems, achieve good environmental benefits, low dehydration cost, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

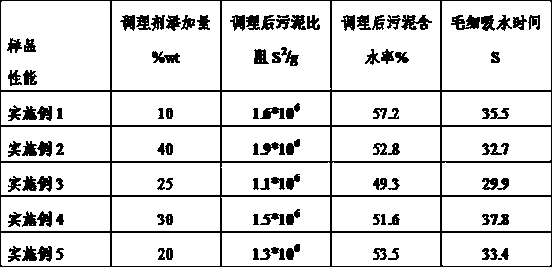

Examples

Embodiment 1

[0027] The deep dehydration conditioner for industrial sludge in this example is made from the following raw materials in parts by weight: 50 parts of rectorite, 30 parts of coal gangue, 30 parts of kaolin, 20 parts of biological bacteria, 16 parts of coconut shell fiber, and 16 parts of cellulose acetate , 20 parts of chitosan, 20 parts of protease, 15 parts of Lactobacillus plantarum, 23 parts of borax, 20 parts of blue-green algae powder, 17 parts of iron sulfate, 17 parts of calcium carbonate, 17 parts of aluminum sulfate, 12 parts of citric acid, 100 parts of deionized water share;

[0028] Among them, the cyanobacteria powder is a powder with a particle size of 80 mesh; it is made of a mixture of biological bacteria dephenolizing bacteria, aniline degrading bacteria, nitrifying bacteria, and flocculating bacteria;

[0029] The preparation method of the industrial sludge deep dehydration conditioner of the present embodiment comprises the following steps:

[0030] S1, ea...

Embodiment 2

[0035] The industrial sludge deep dehydration conditioner in this embodiment is made of the following raw materials in parts by weight: 100 parts of rectorite, 80 parts of coal gangue, 70 parts of kaolin, 40 parts of biological bacteria, 32 parts of coconut shell fiber, and 32 parts of cellulose acetate , 35 parts of chitosan, 28 parts of protease, 25 parts of Lactobacillus plantarum, 40 parts of borax, 36 parts of blue-green algae powder, 37 parts of iron sulfate, 37 parts of calcium carbonate, 37 parts of aluminum sulfate, 28 parts of citric acid, 150 parts of deionized water share;

[0036] Among them, the cyanobacteria powder is a powder with a particle size of 100 mesh; it is made of a mixture of biological bacteria dephenolizing bacteria, aniline degrading bacteria, and nitrifying bacteria;

[0037] The preparation method of the industrial sludge deep dehydration conditioner of the present embodiment comprises the following steps:

[0038] S1, each raw material is weigh...

Embodiment 3

[0043] The industrial sludge deep dehydration conditioner in this embodiment is made of the following raw materials in parts by weight: 75 parts of rectorite, 50 parts of coal gangue, 50 parts of kaolin, 30 parts of biological bacteria, 24 parts of coconut shell fiber, and 24 parts of cellulose acetate , 28 parts of chitosan, 24 parts of protease, 20 parts of Lactobacillus plantarum, 32 parts of borax, 28 parts of blue-green algae powder, 27 parts of iron sulfate, 27 parts of calcium carbonate, 27 parts of aluminum sulfate, 20 parts of citric acid, 125 parts of deionized water share;

[0044] Among them, the cyanobacteria powder is a powder with a particle size of 90 mesh; it is made of a mixture of biological bacteria dephenolizing bacteria, aniline degrading bacteria, nitrifying bacteria, and flocculating bacteria;

[0045] The preparation method of the industrial sludge deep dehydration conditioner of the present embodiment comprises the following steps:

[0046] S1, take ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com