Lithium battery waste liquid treatment technology

A treatment process, lithium battery technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Water requirements, low denitrification efficiency, etc., to achieve the effect of maintaining the microbial content and decontamination ability, increasing the content, and improving the treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

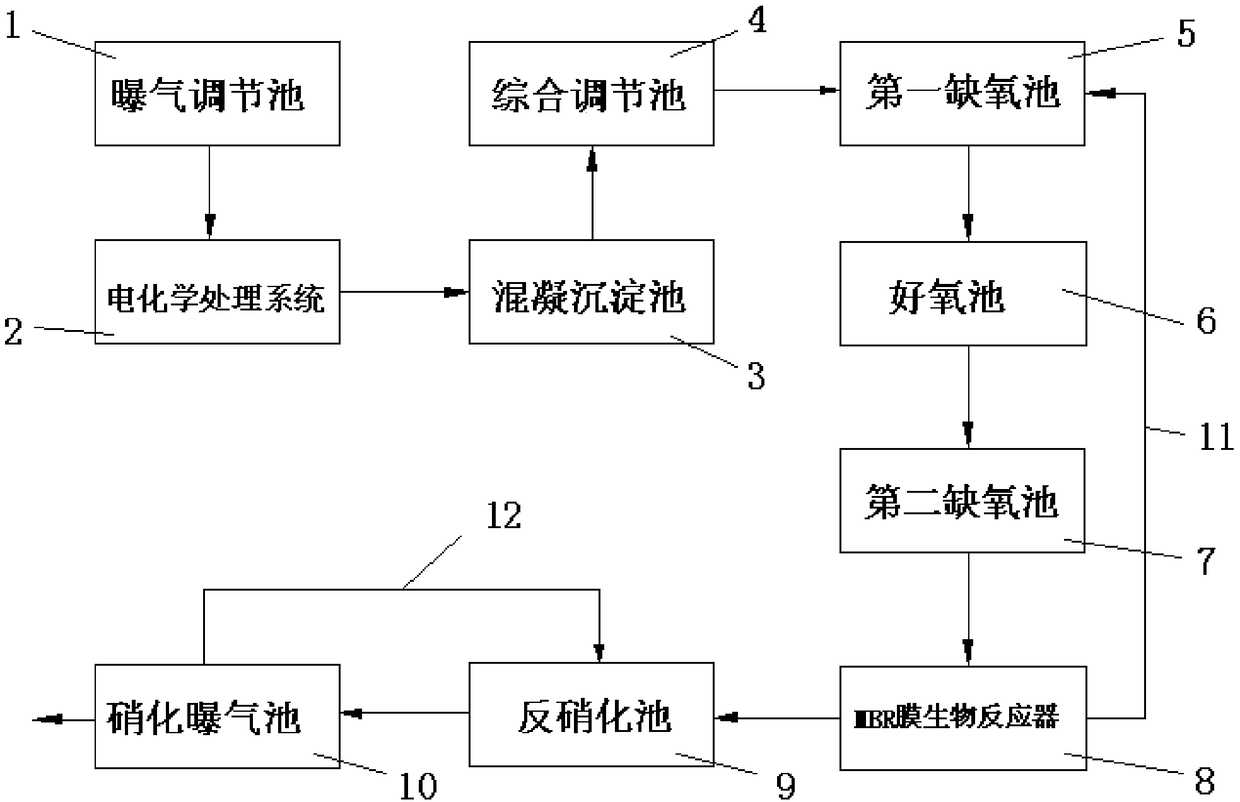

[0021] figure 1 It is a schematic flow chart of the treatment process of lithium battery waste liquid. The lithium battery waste liquid first flows into the aeration regulating tank 1 and is stirred in the aeration regulating tank 1. The ratio of aeration gas to water is 1:1, and the residence time is 6h. , enter the electrochemical treatment system 2 after processing.

[0022] In the electrochemical treatment system 2, the voltage between the two pole plates of the electrochemical treatment system 2 is 5V, the pole distance is 3cm, and the electrocoagulation reaction time is 0.1h to further remove pollutants by electrocoagulation, and the next step is to flow into the coagulation sedimentation tank 3. The coagulation-sedimentation tank 3 performs sedimentation treatment on the lithium battery waste liquid, and after the treatment, it continues to flow to the comprehensive adjustment tank 4 that uses domestic sewage as nutrients. The amount of domestic sewage is 5% of the ma...

Embodiment 2

[0026] figure 1 It is a schematic flow chart of the treatment process of lithium battery waste liquid. The lithium battery waste liquid first flows into the aeration regulating tank 1, and is stirred in the aeration regulating tank 1. The aeration gas-water ratio is 4:1, and the residence time is 12h. , enter the electrochemical treatment system 2 after processing.

[0027] In the electrochemical treatment system 2, the voltage between the two pole plates of the electrochemical treatment system 2 is 45V, the pole distance is 5cm, and the electrocoagulation reaction time is 2h for electrocoagulation to further remove pollutants, and the next step is to flow into the coagulation sedimentation tank 3 . The coagulation-sedimentation tank 3 performs sedimentation treatment on the lithium battery waste liquid, and after the treatment, it continues to flow to the comprehensive adjustment tank 4 that uses domestic sewage as nutrients. The amount of domestic sewage is 35% of the mass...

Embodiment 3

[0031] figure 1 It is a schematic flow chart of the treatment process of lithium battery waste liquid. The lithium battery waste liquid first flows into the aeration regulating tank 1 and is stirred in the aeration regulating tank 1. The ratio of aeration gas to water is 6:1, and the residence time is 18h. ,

[0032] After processing, enter the electrochemical treatment system 2.

[0033] In the electrochemical treatment system 2, the voltage between the two pole plates of the electrochemical treatment system 2 is 85V, the pole distance is 7cm, and the electrocoagulation reaction time is 3h for electrocoagulation to further remove pollutants, and the next step is to flow into the coagulation sedimentation tank 3 . The coagulation-sedimentation tank 3 performs sedimentation treatment on the lithium battery waste liquid, and after the treatment, it continues to flow to the comprehensive adjustment tank 4 that uses domestic sewage as nutrients. The amount of domestic sewage is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com