Sea tying carrying pole device and sea tying method for heavy equipment

A technology of heavy equipment and shoulder poles, which is applied to the device for preventing multi-way movement of goods, load handling device, transportation and packaging, etc. It can solve the problems of high transportation cost, great influence of lashing operations, and long operation cycle, etc., to achieve guaranteed reliability. Ease of dismantling, avoiding difficulties in lifting and installation, saving cost and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

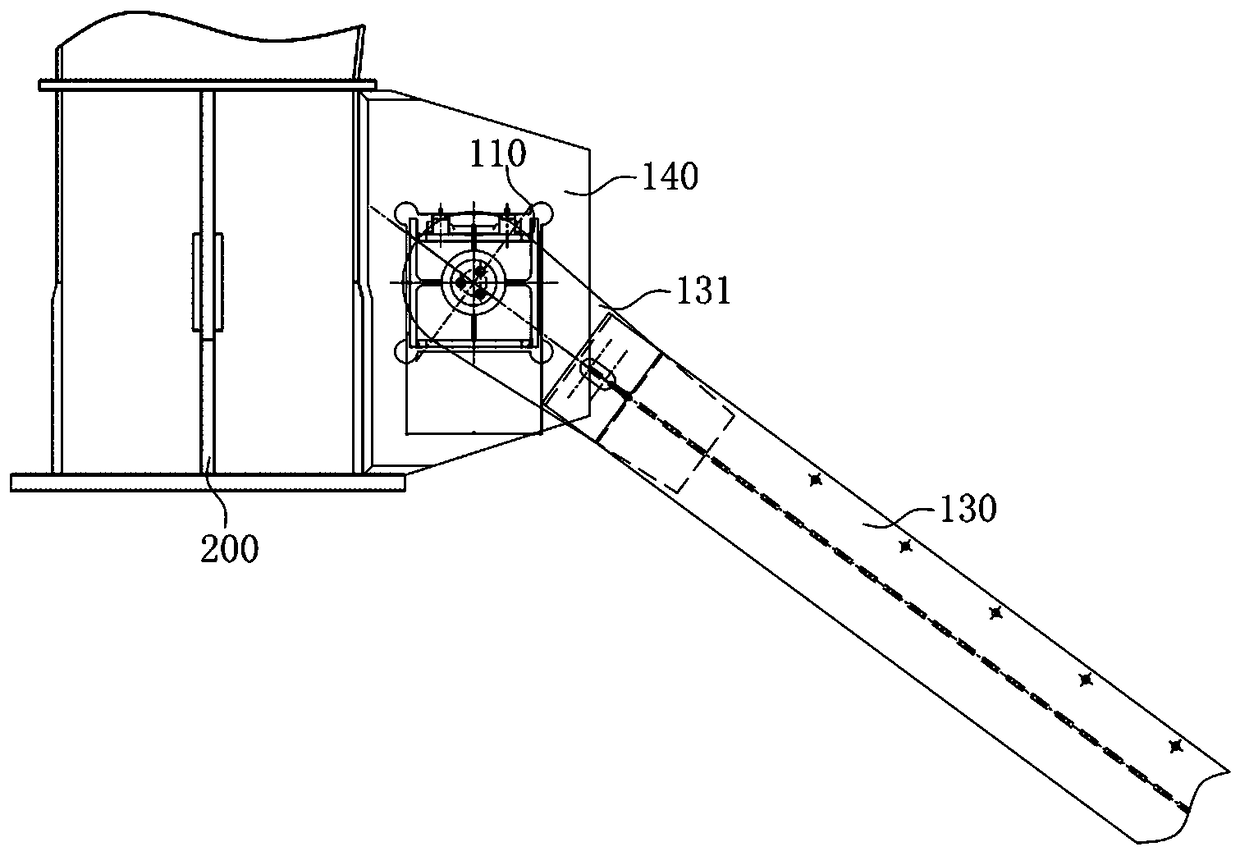

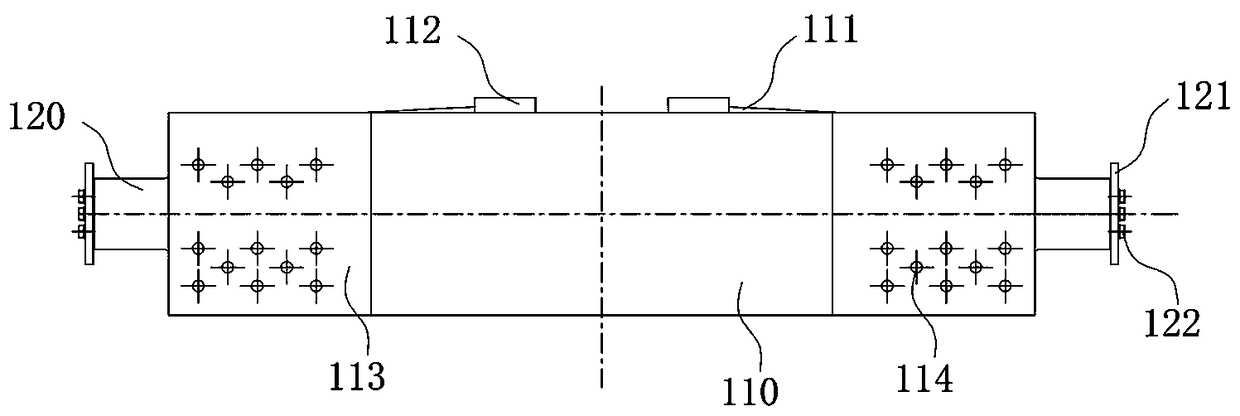

[0036] see Figure 1-Figure 7 , the present invention is a sea-tied shoulder pole device for heavy equipment, comprising a shoulder pole main body 110, a pin shaft 120 and a support beam 130, the pin shaft 120 is matched and arranged in the shoulder pole main body 110, and the end of the pin shaft 120 extends out of the shoulder pole main body 110; The upper end of the support beam 130 is matched and sleeved on the end of the pin shaft 120, and both ends of the pin shaft 120 are provided with a shaft end limit assembly. The shaft end limit assembly and the main body of the shoulder pole limit the lateral sliding movement of the support beam. The shaft end limit assembly in the example is an end cover 121 fixedly arranged at the end of the pin shaft. The end cover 121 and the pin shaft 120 are fixedly connected by bolts 122, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com