Casting machine

A casting machine and stretching box technology, applied in thin material processing, coating, metal processing, etc., can solve the problems of low productivity and inability to cut longer film tapes, and achieve the effect of avoiding low productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

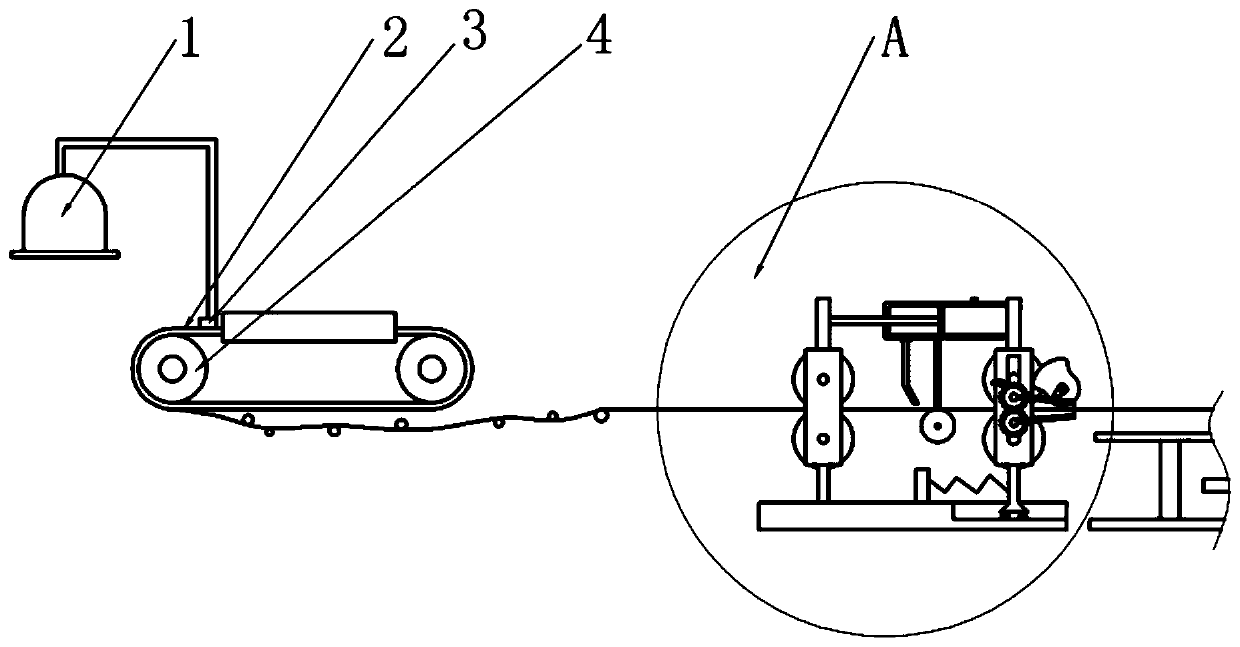

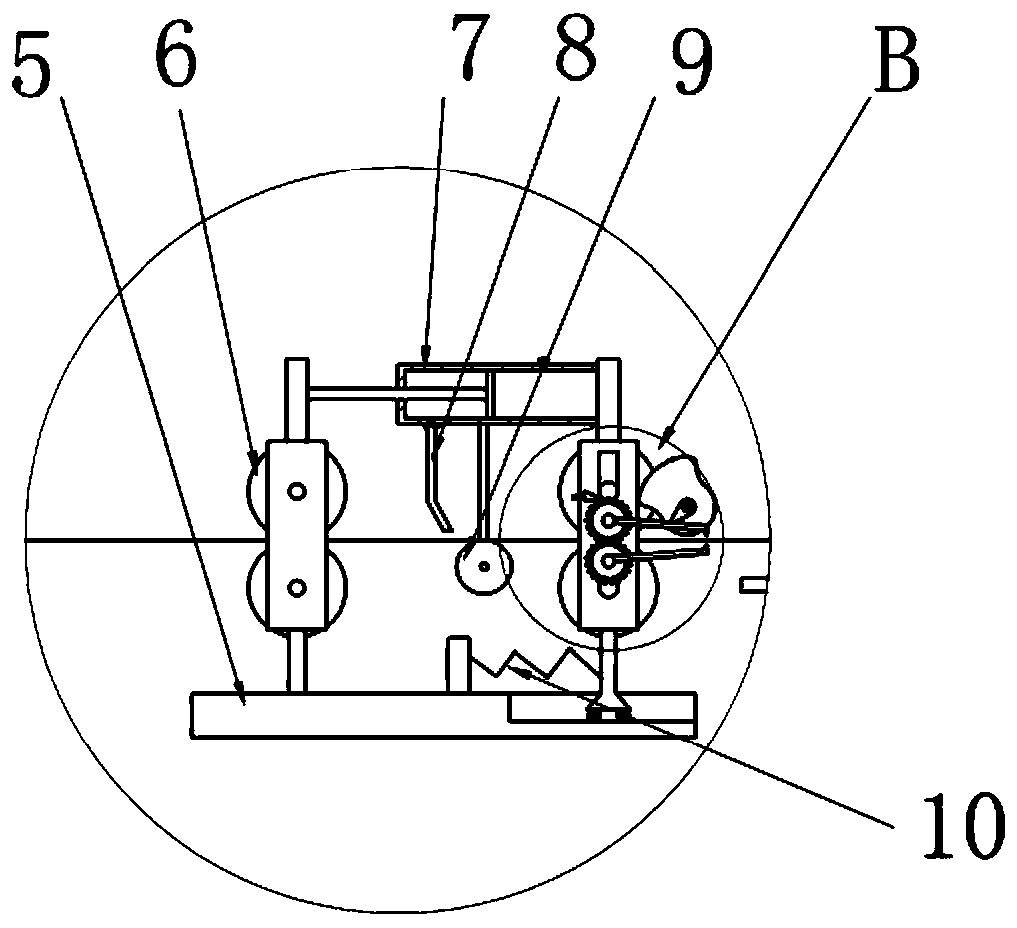

[0022] Embodiment: the casting machine in this scheme, as figure 1 , figure 2 and image 3 As shown, it includes a main frame 5, a slurry supply device 1, a casting box 3, a cutting device and a conveying device for sending the film tape to the cutting device. The slurry supply device 1 communicates with the casting box 3 , and the conveying device includes a base belt 2 and two driving rollers 4 , the base belt 2 is set on the two driving rollers 4 , and the driving roller 4 is rotatably connected to the main frame 5 . The casting box 3 is located above the base tape 2 and covers the base tape 2 . The cutting device includes an active transmission mechanism and a cutting transmission mechanism, and the transmission device, the active transmission mechanism and the cutting transmission mechanism are arranged in sequence from left to right.

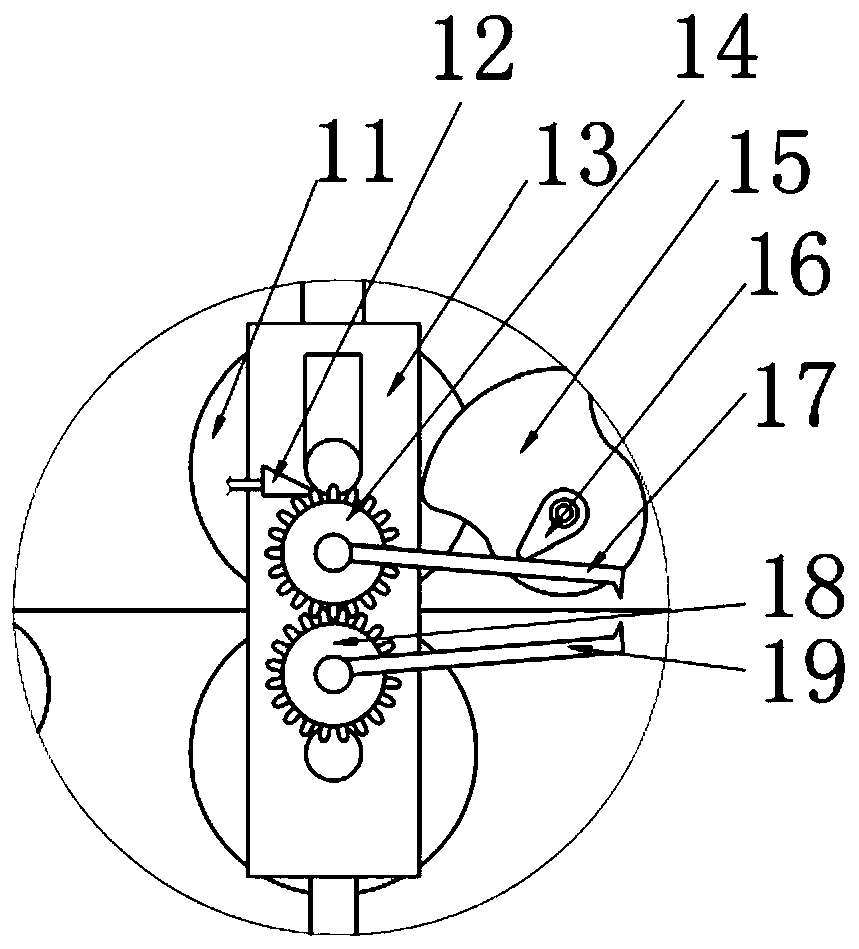

[0023] The driving transmission mechanism includes a driving roller 6 for actively conveying the film belt. The driving roller 6 is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com