Multi-grading concrete production system for bridge pier pouring and preparation technology thereof

A production system, concrete technology, applied in clay preparation equipment, mixing operation control, mixing plant, etc., to achieve high production efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

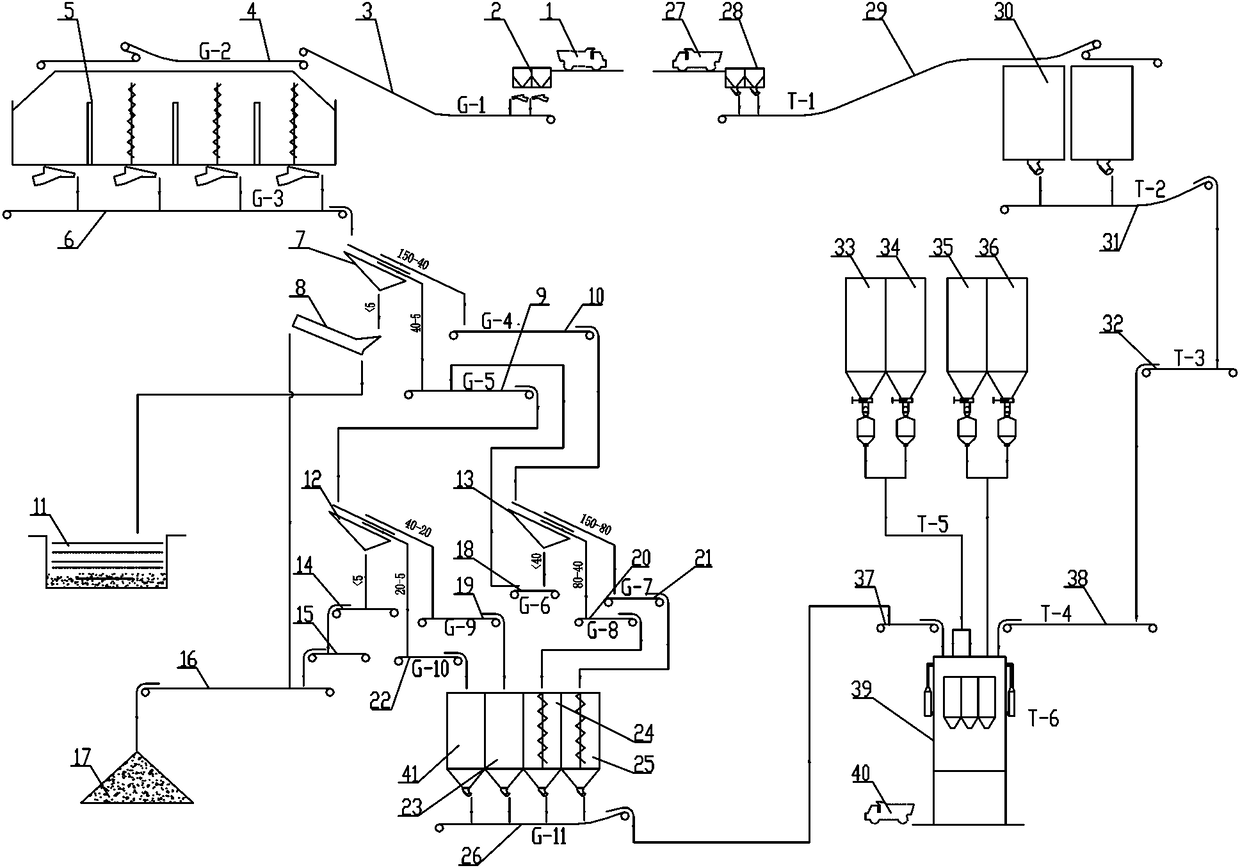

[0041] see figure 1 , a multi-graded concrete production system for pier pouring, which includes an aggregate lower hopper 2, and the discharge port of the aggregate lower hopper 2 is connected with a second aggregate conveyor belt 4 through a first aggregate conveyor belt 3, and the An aggregate vibrating feeder 5 is arranged directly below the second aggregate conveyor belt 4, and the feed opening of the aggregate vibrating feeder 5 is connected to the first trommel 7 through the third aggregate conveyor belt 6, so that The discharge port of the first drum sieve 7 is respectively provided with a small particle size aggregate conveyor belt 8, a medium particle size aggregate conveyor belt 9 and a large particle size aggregate conveyor belt 10; the outlet of the medium particle size aggregate conveyor belt 9 The feed port is connected with the second trommel 12, and the large-size aggregate conveyor belt 10 is connected with the third trommel 13; the discharge port of the seco...

Embodiment 2

[0050] The process flow of this system is divided into two parts: coarse aggregate preparation process and other raw material preparation process:

[0051] The coarse aggregate preparation process includes:

[0052] G-1: Transport the coarse aggregate to the first aggregate conveyor belt 3 through the aggregate lower hopper 2;

[0053] G-2: The coarse aggregate on the first aggregate conveyor belt 3 will fall onto the aggregate vibrating feeder 5;

[0054] G-3: The aggregate after the aggregate vibrating feeder 5 unloads falls to the third aggregate conveyor belt 6;

[0055] G-4: The aggregate enters the first trommel 7, and the aggregate with a particle size between 40 and 150 will enter the large-size aggregate conveyor belt 10;

[0056] G-5: Aggregate with a particle size between 5 and 40 will enter the medium-sized aggregate conveyor belt 9, and aggregates with a particle size smaller than 5 will enter the small-sized aggregate conveyor belt 8, and finally enter the Sed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com